Variable air volume air conditioning system total air volume control method based on operation curve

A technology for operating curves and air-conditioning systems, applied in the direction of high-efficiency regulation technology, climate sustainability, mechanical equipment, etc., which can solve the problems of slow regulation speed, insufficient stability, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

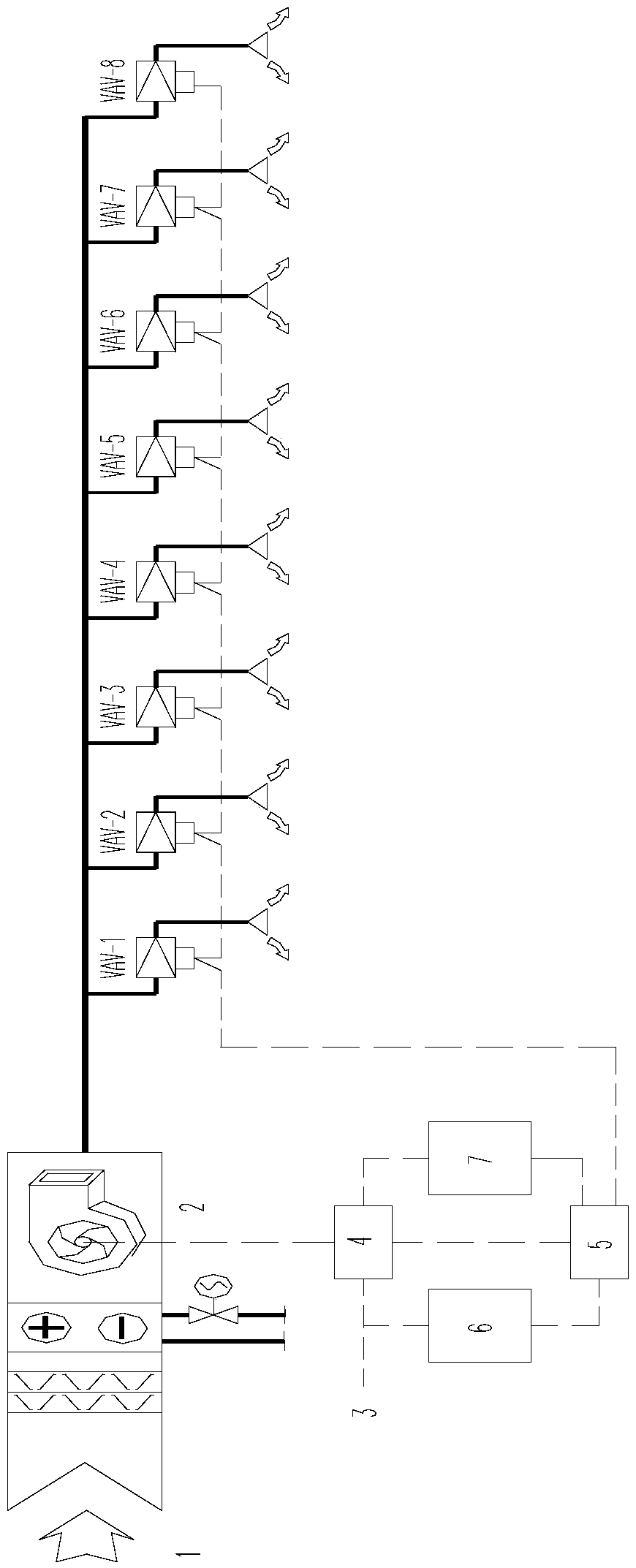

[0041] see figure 1 Schematic diagram of the principle of the total air volume control method based on the operating curve according to the embodiment of the present invention, wherein the entire control system includes fresh air and return air input terminal 1, blower fan 2, power input 3, frequency converter 4, AHU DDC controller 5, fan power consumption A detection unit 6, a fan speed detection unit 7 and a plurality of VAV units.

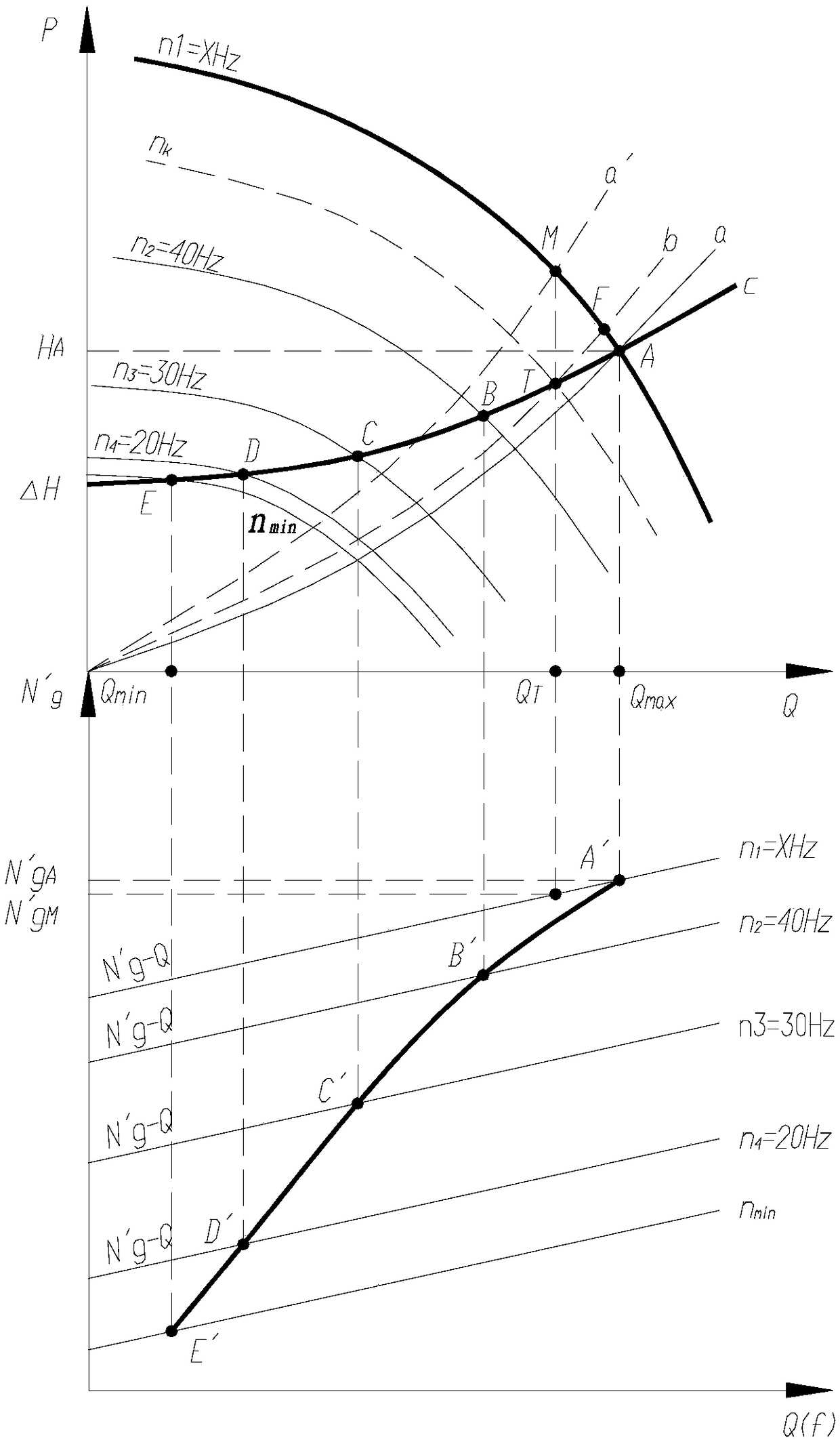

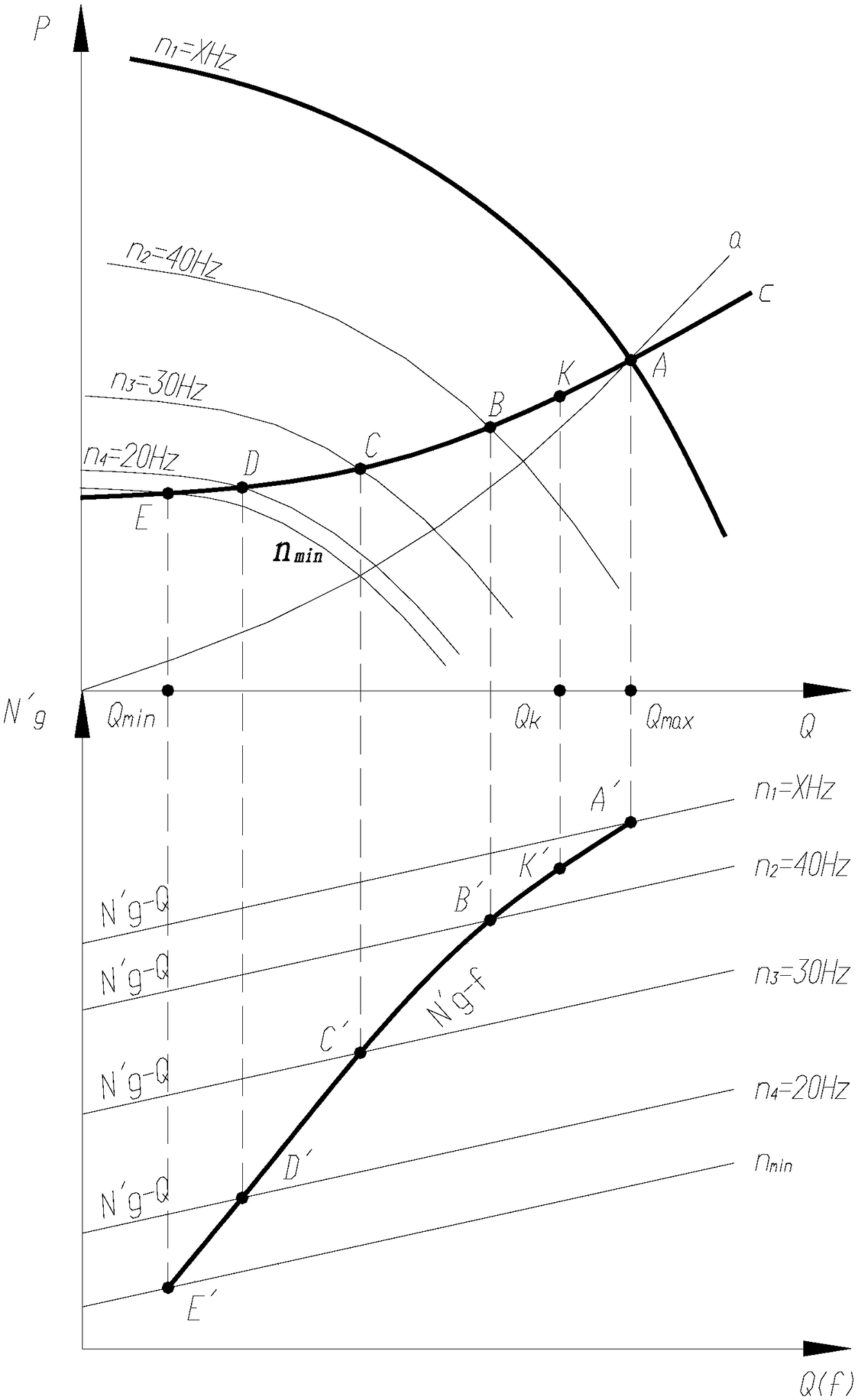

[0042] The method for controlling the total air volume of a variable air volume air-conditioning system (VAV) based on an operating curve comprises the following steps:

[0043] Step 1: Obtain the resistance characteristic curve a of the pipeline system, and its mathematical expression is: P=S a ·Q 2 ; where

[0044] P--Pipeline resistance, Pa;

[0045] S a - pipeline resistance coefficient;

[0046] Q-air volume, m 3 / h;

[0047] Step 2: Obtain fan characteristic curves at various speeds, including P-Q curves and N g ′-Q curve, where P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com