Printing pressure measurement and correction method of plane screen printing machine

A technology of printing pressure and correction method, applied in force/torque/work measuring instruments, printing, printing presses, etc., can solve the problems affecting the balanced transmission of printing pressure, affecting the effect of flat screen printing production process, etc., to overcome the blindness of control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is further described:

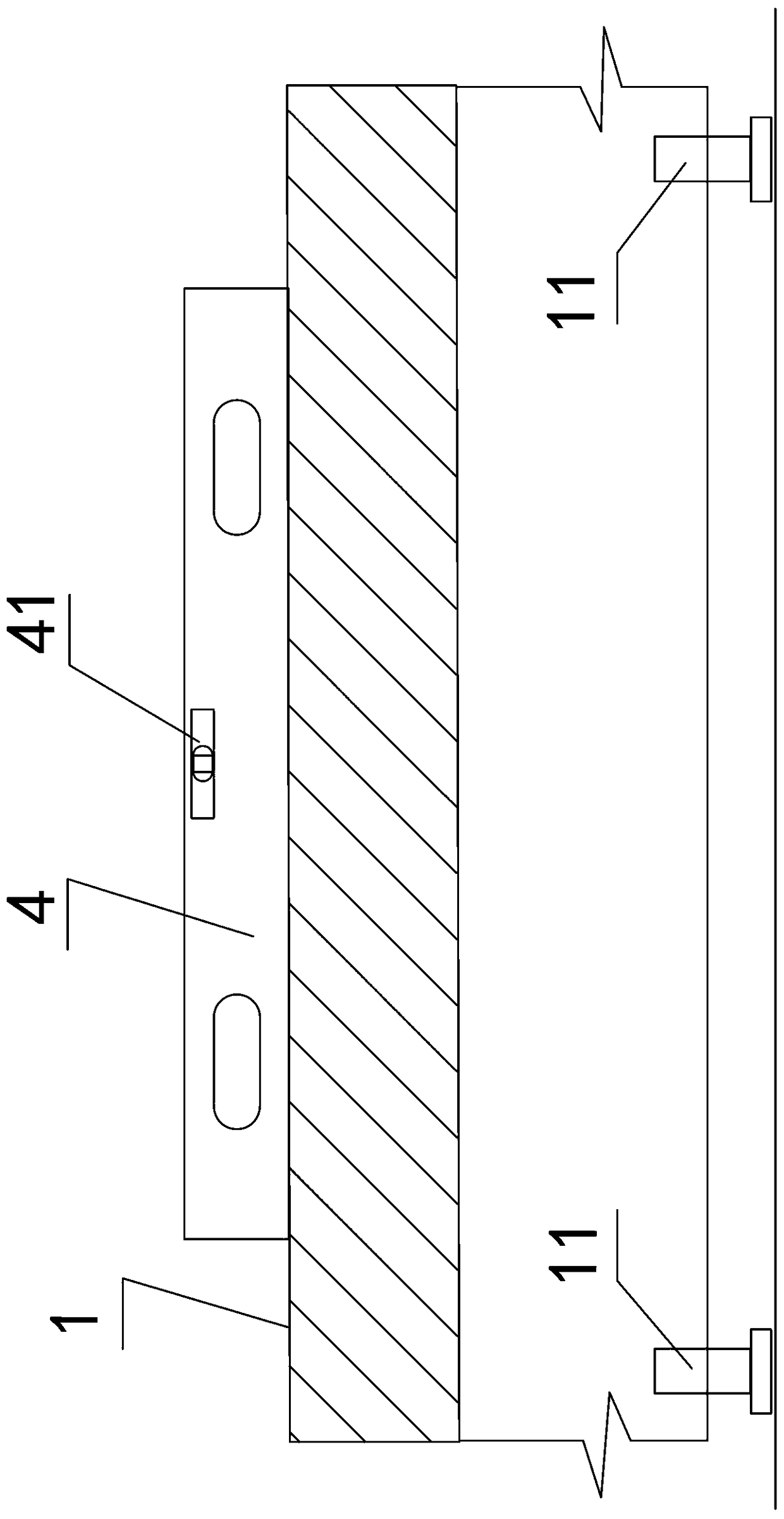

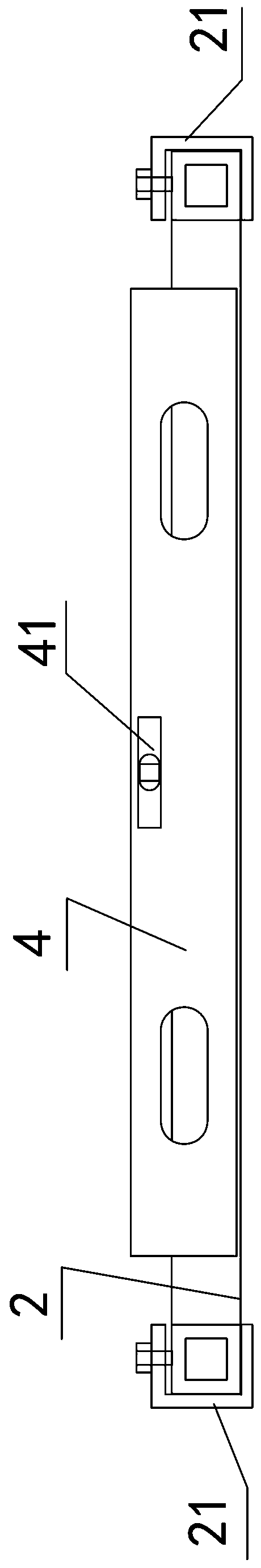

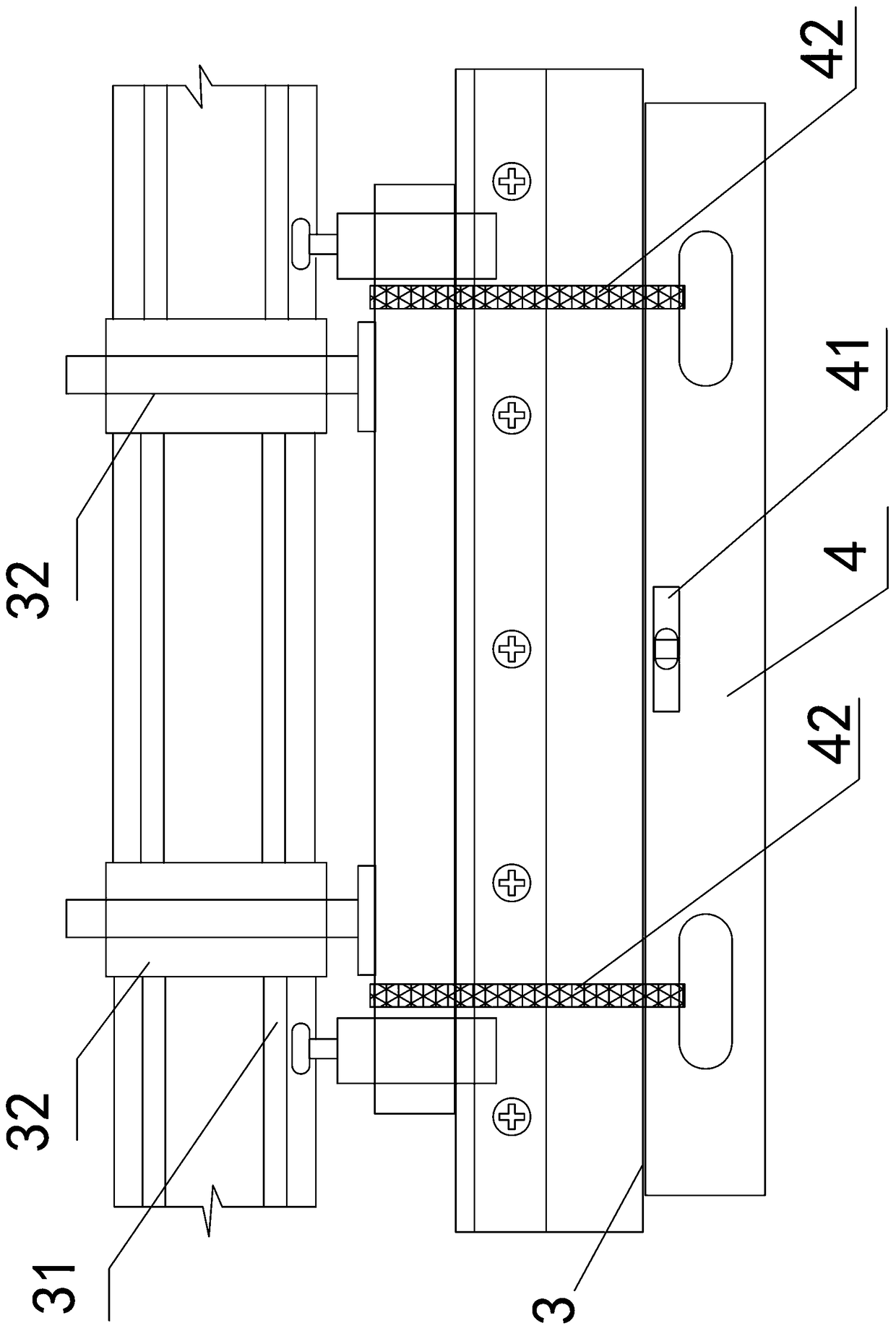

[0017] Based on the measurement and correction of the printing pressure of the flat screen printing machine, specifically through the horizontal correction of the printing platform, screen, and knife edge, the key parameters of the printing pressure in the flat screen printing production process can be balanced to maintain the printing pressure of the printing knife edge. On the stencil, the printing pressure acts synchronously on the printing workpiece of the platform, which completely overcomes the blindness of the control of the printing production process.

[0018] For this reason, the method for measuring and correcting the printing pressure of a plane screen printing machine according to the present invention includes: using a level to measure and correct the screen printing machine platform in both longitudinal and transverse directions; The posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com