Drilling and sampling device used for geological prospecting

A sampling device and geological exploration technology, applied in the field of geological exploration, can solve problems such as single function, laborious work, increased labor intensity of workers, etc., and achieve the effect of increasing work efficiency, reducing labor intensity, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

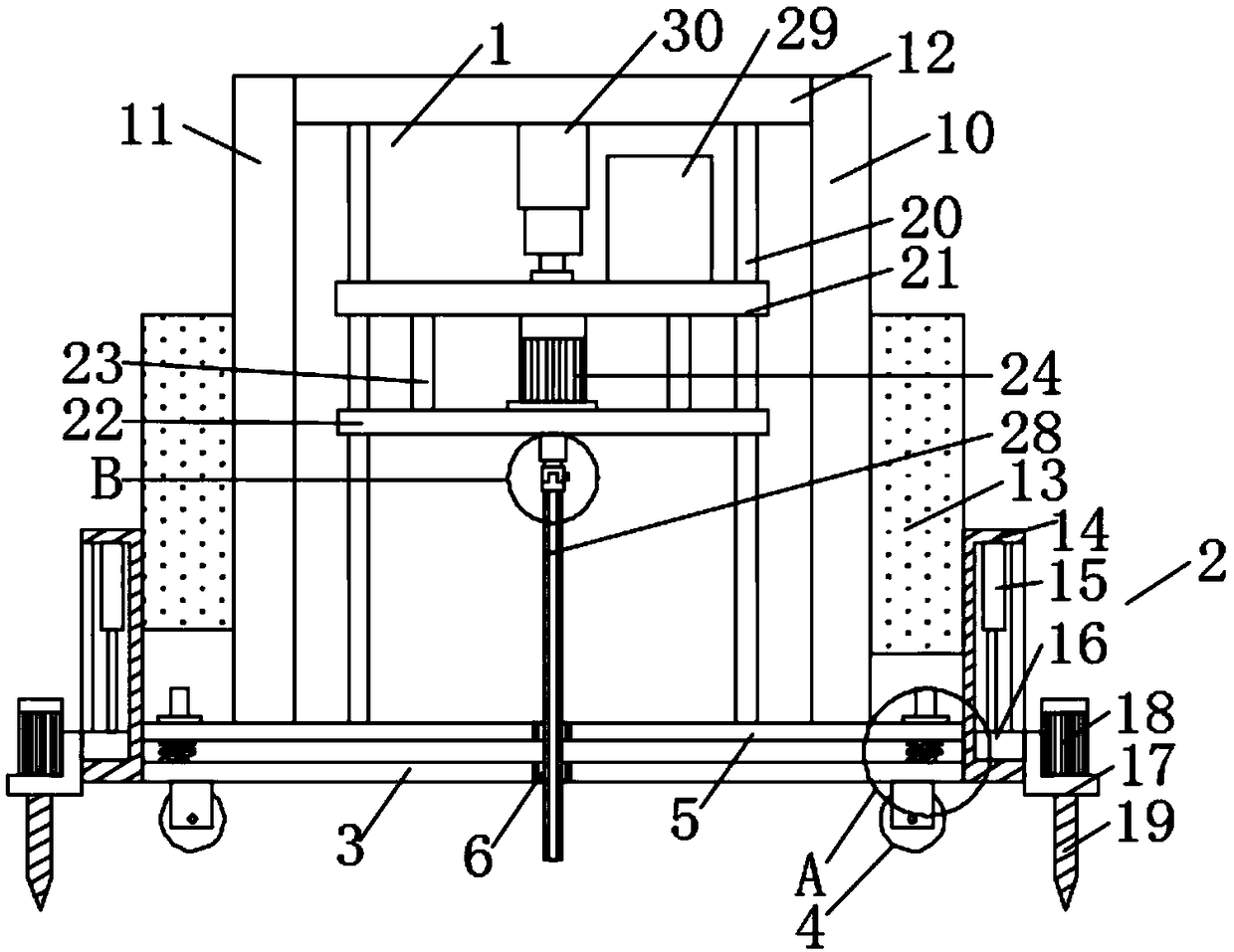

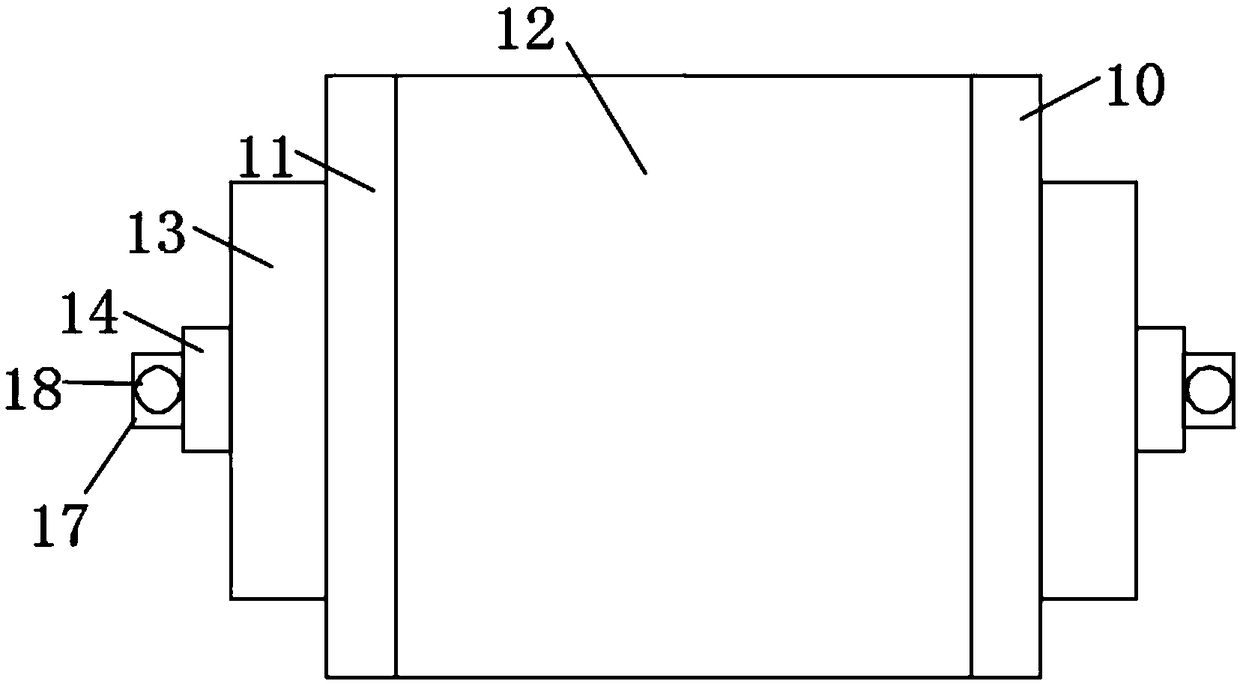

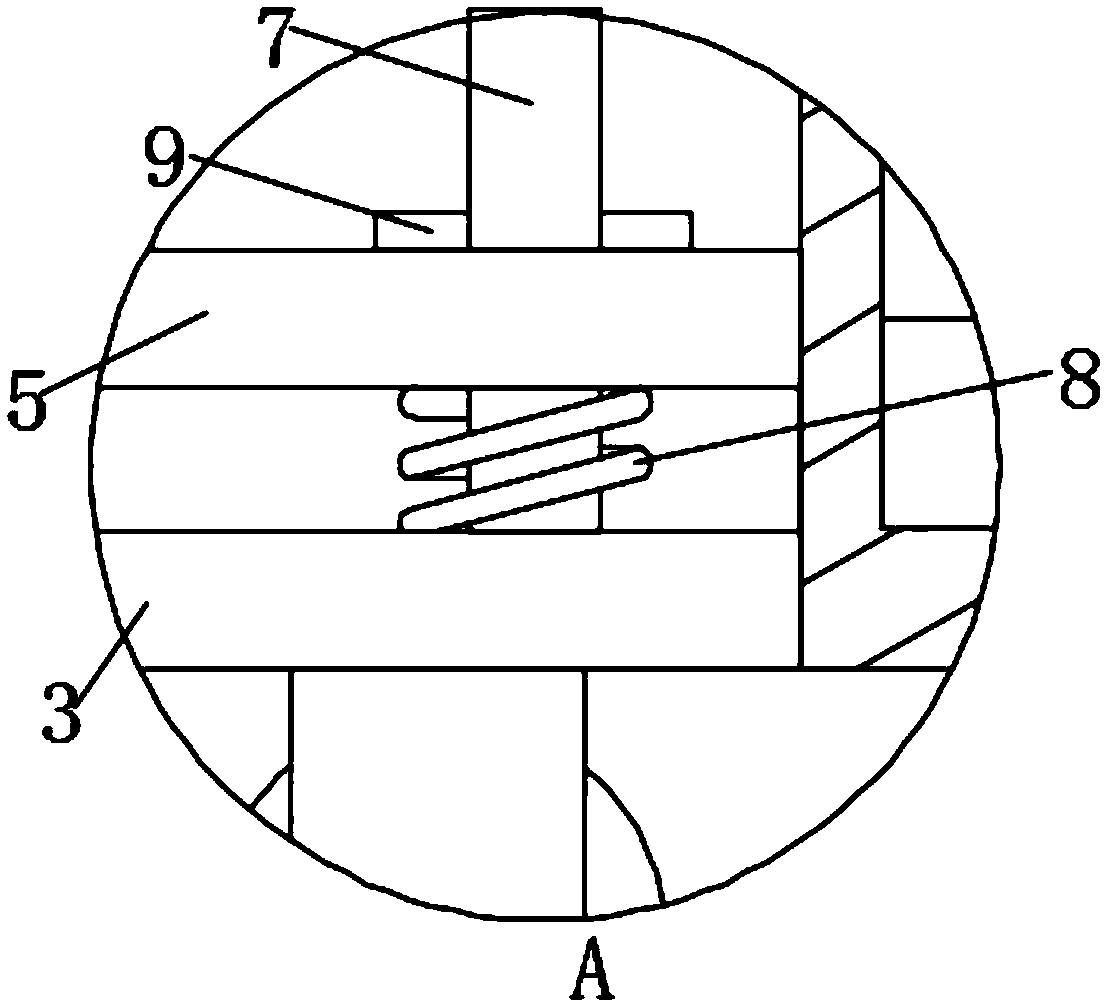

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solution: a drilling sampling device for geological exploration, comprising a lifting mechanism 1 and a fixing mechanism 2, the fixing mechanism 2 is provided with a lifting mechanism 1 above the fixing mechanism 2 A supporting base plate 3, universal wheels 4, a second supporting base plate 5, a sampling hole 6, a limit sliding rod 7, a buffer spring 8, a limit pin 9, a first fixed plate 10, a second fixed plate 11, and a fixed top plate 12 , The counterweight 13, the fixed chute 14, the first electric telescopic rod 15, the fixed slider 16, the lifting slider 17, the fixed motor 18 and the fixed drill bit 19. The four corners of the top of the first support base plate 3 are all limited in connection The second support bottom plate 5 is provided above the first support bottom plate 3, and the limit slide rods 7 all pass through the top of the second support bottom plate 5. Both are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com