Method and apparatus for crimping and cutting pouched dough products

一种切割设备、面团的技术,应用在面团成型和切割设备、面团成型的机械或设备、处理面团等方向,能够解决内部填充材料泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

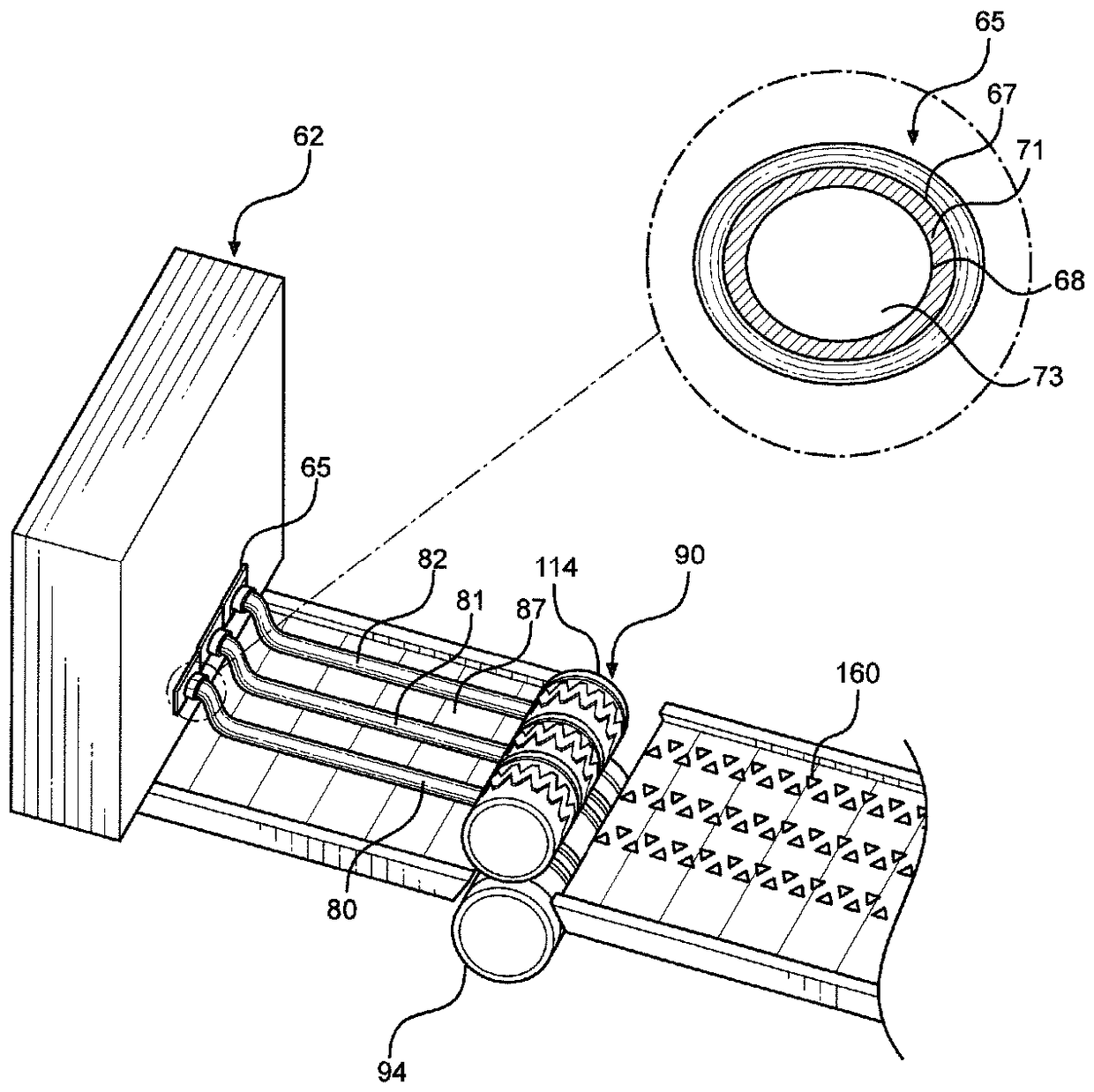

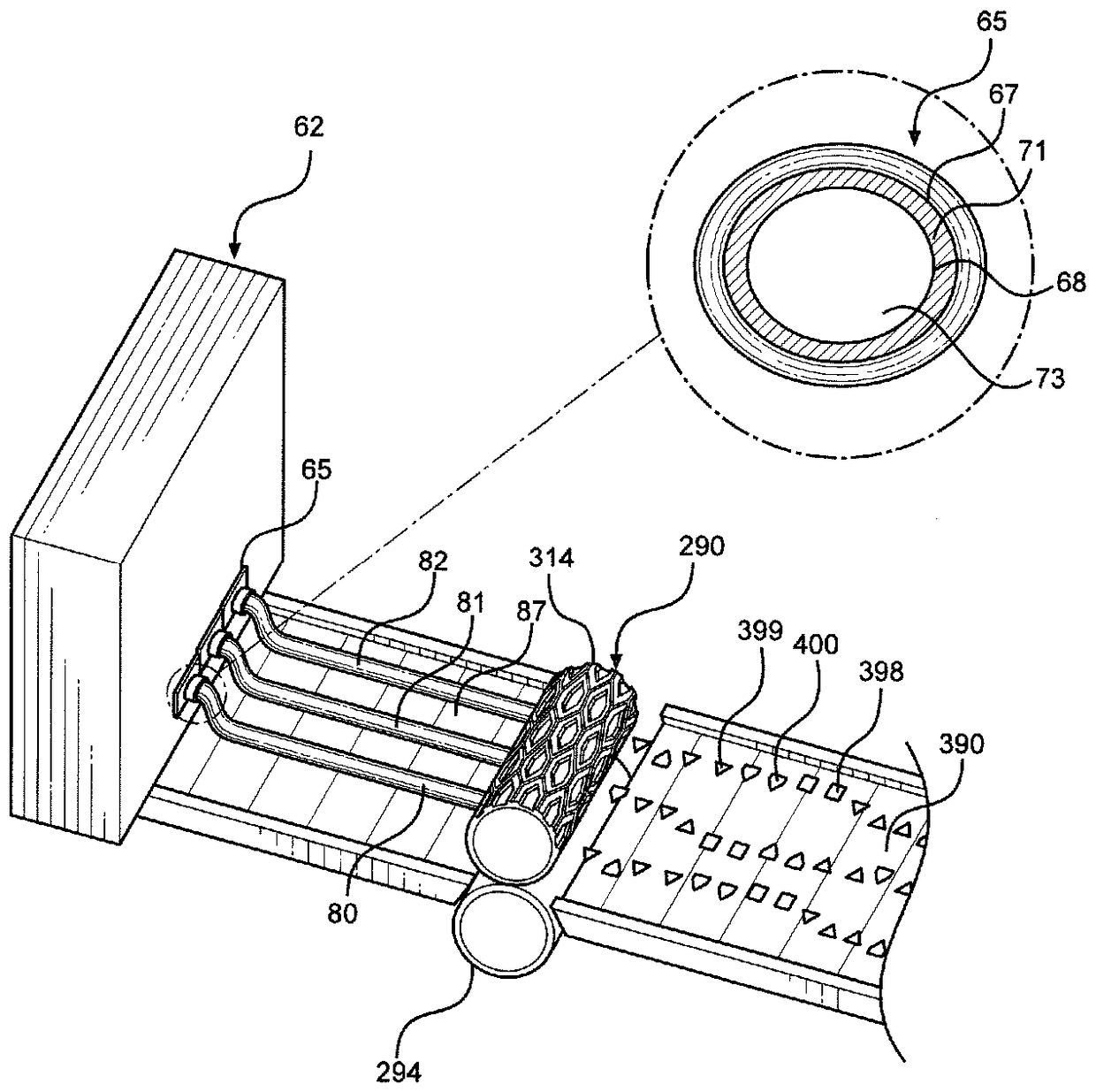

[0013] As mentioned above, figure 1 and 2 The originally conceived crimping and cutting arrangement is shown. This arrangement uses a multi-row extruder 62 having a plurality of laterally spaced heads, one of which is indicated at 65 . As shown in the enlarged view, each head 65 includes an outer channel-defining member 67 and a concentric inner channel-defining member 68 forming an outer die opening 71 and a central die opening 73 . Outer dough material 72 (which may be cooked or uncooked so long as it can be sealed with pressure) flows through outer die opening 71 while filling material 75 flows through central die opening 73 at the same time. With the arrangement shown, the extruder 62 forms a plurality of elongated laterally spaced rows (eg rows) of food products that are placed in continuous ropes 80-82 on a common conveyor 87 on.

[0014] A combined nip and cut assembly is provided downstream of the extruder 62 , indicated generally at 90 , extending across the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com