External-pressure-type hollow fiber membrane module

A fiber membrane and external pressure technology, applied in the field of external pressure hollow fiber membrane modules, can solve the problems of reducing the filtration efficiency of hollow fiber membranes, reducing the filtration efficiency, and increasing the contact area, so as to achieve less uneven flow, less fouling, and non-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

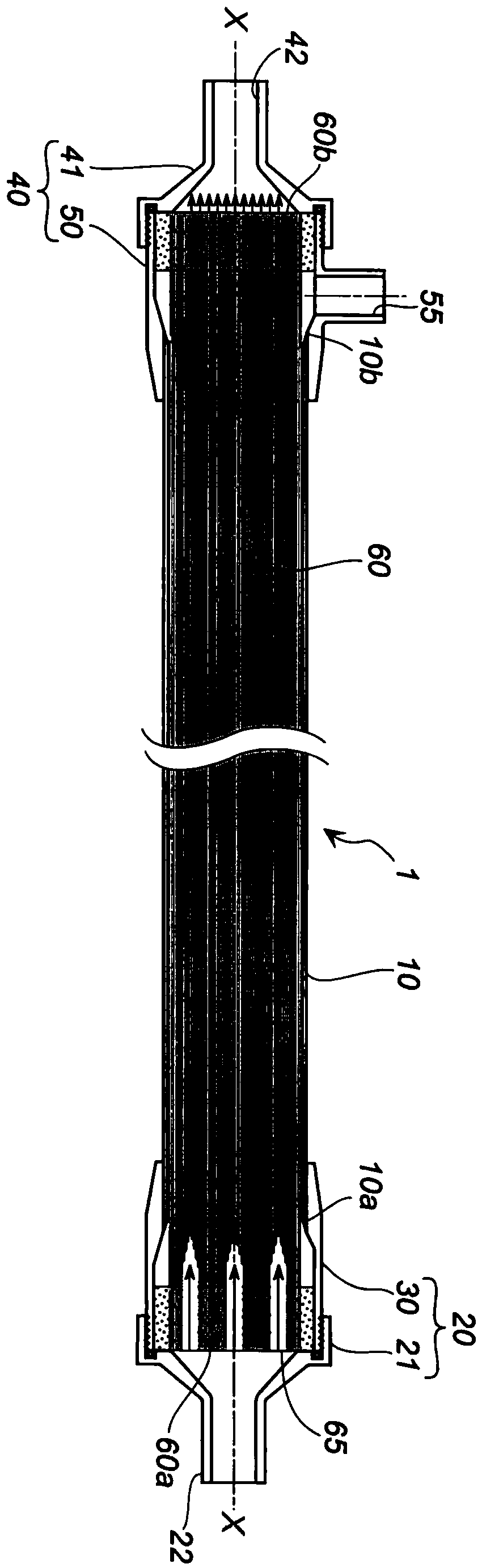

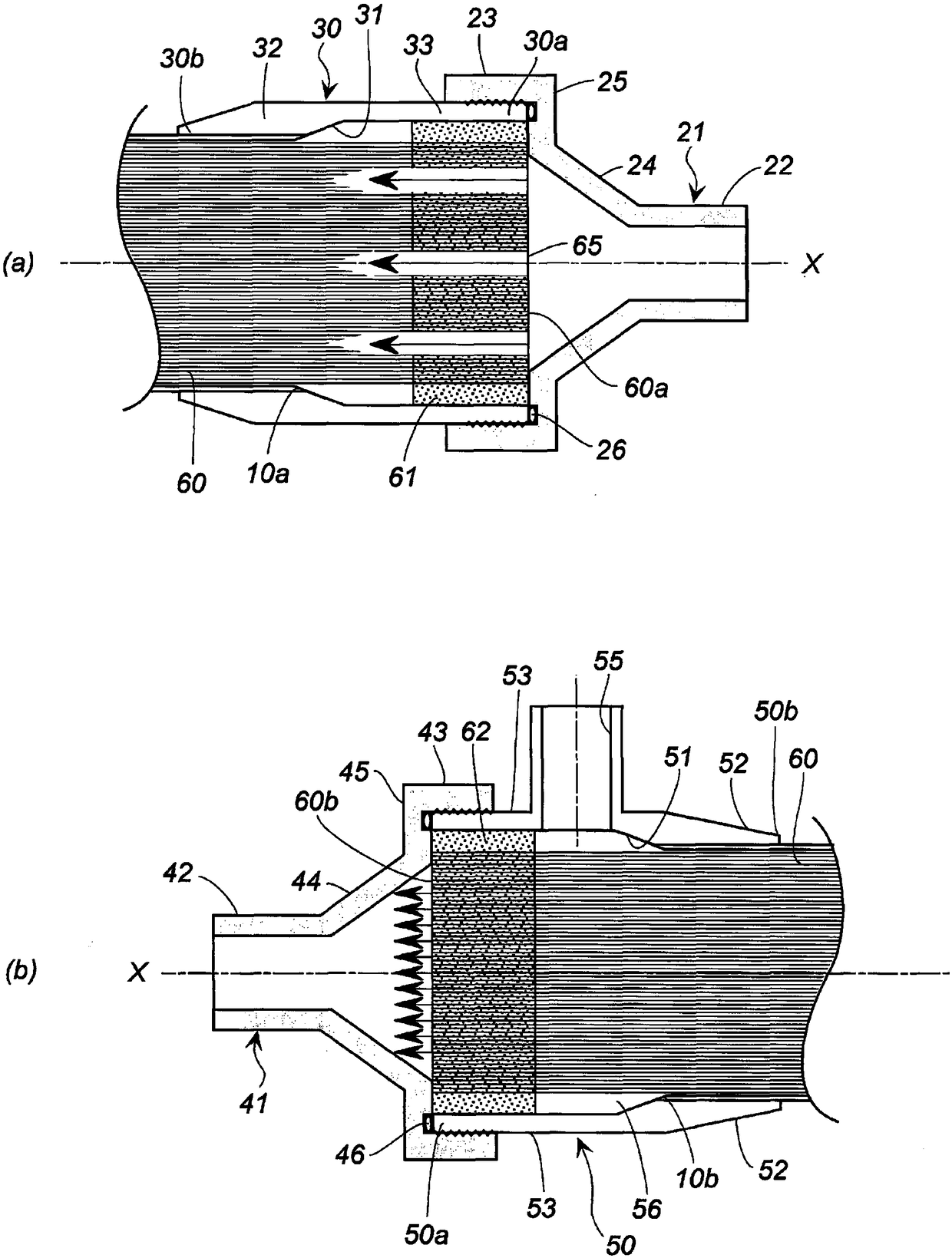

[0079] Use with figure 1 Filtration operation was carried out with the vertically placed hollow fiber membrane module 1 having the cylindrical casing, the two caps 20 and 40 on both ends, the first annular holder 30 , and the second annular holder 50 .

[0080] Both ends of the hollow fiber membrane bundle are fixed with a polyurethane resin-based adhesive.

[0081] (Hollow Fiber Membrane Module)

[0082] Cylindrical shell: made of vinyl chloride, outer diameter 17cm, inner diameter 13cm

[0083] (hollow fiber membrane bundle)

[0084] Cellulose acetate hollow fiber membrane

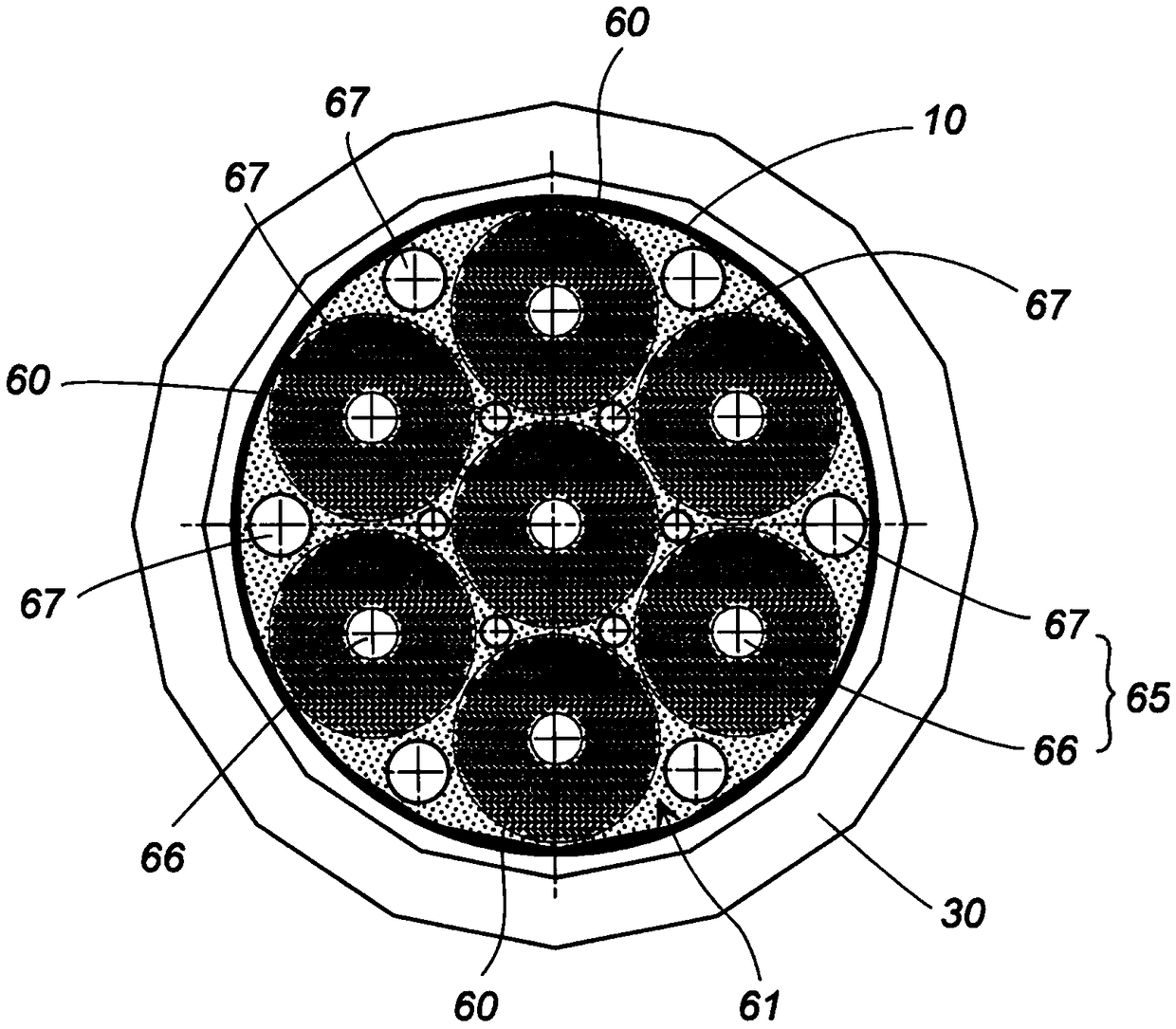

[0085] Number of hollow fiber membrane bundles: 7 bundles

[0086] Hollow fiber membrane bundle outer diameter: 5cm

[0087] Hollow fiber membrane bundle thickness (t1): 2cm

[0088] (1st fixed layer 61)

[0089] In the cross-sectional area (A1) in the radial direction of the first fixed layer 61, the ratio of the total opening area (A2) of the first group of raw water introduction holes 66 to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap