Method for installation of seat slurry method construction packing plate

An installation method and a technology in construction, which are applied in the field of backing plate installation in the grouting method construction, can solve problems such as oblique strikes, and achieve the effect of not being prone to air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

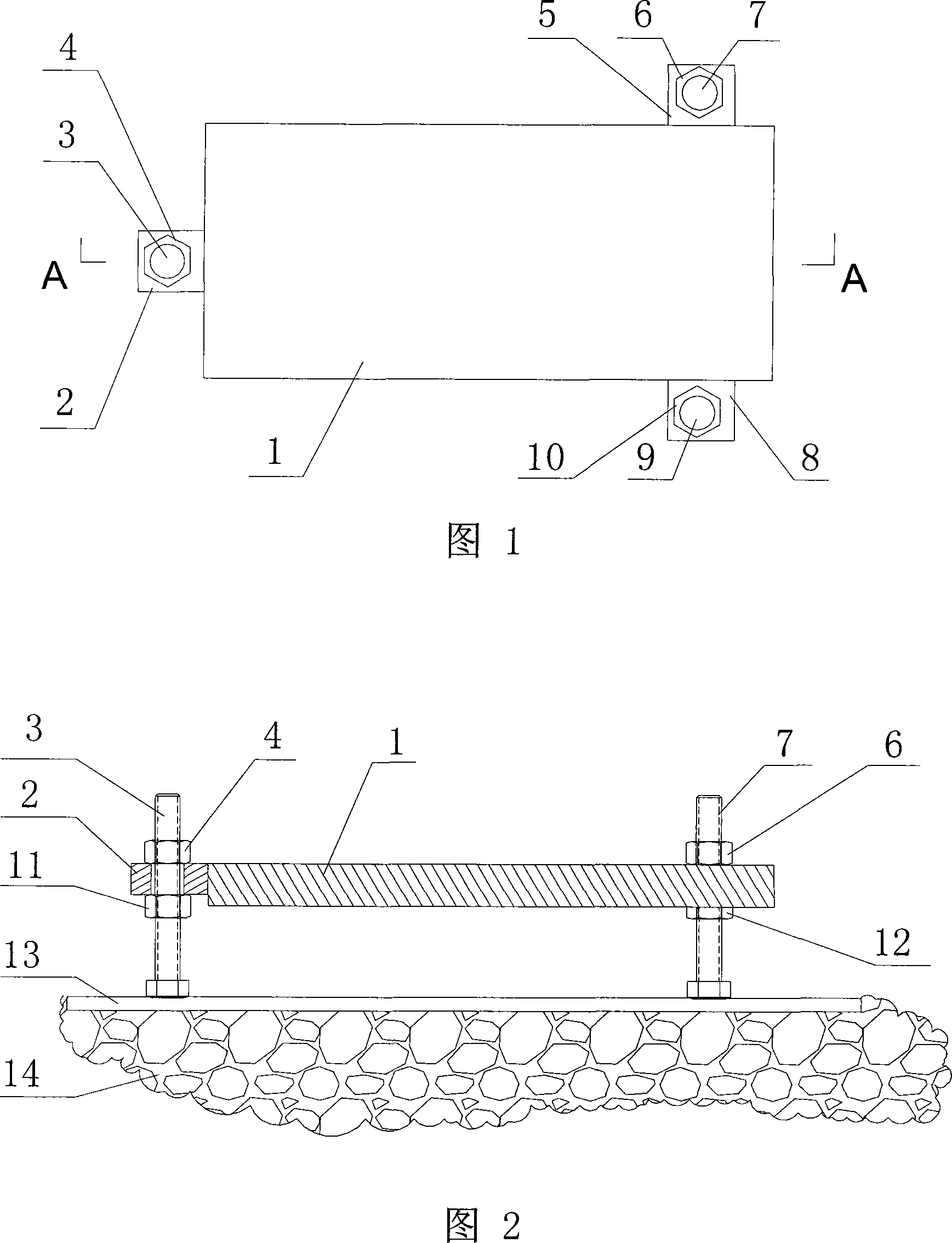

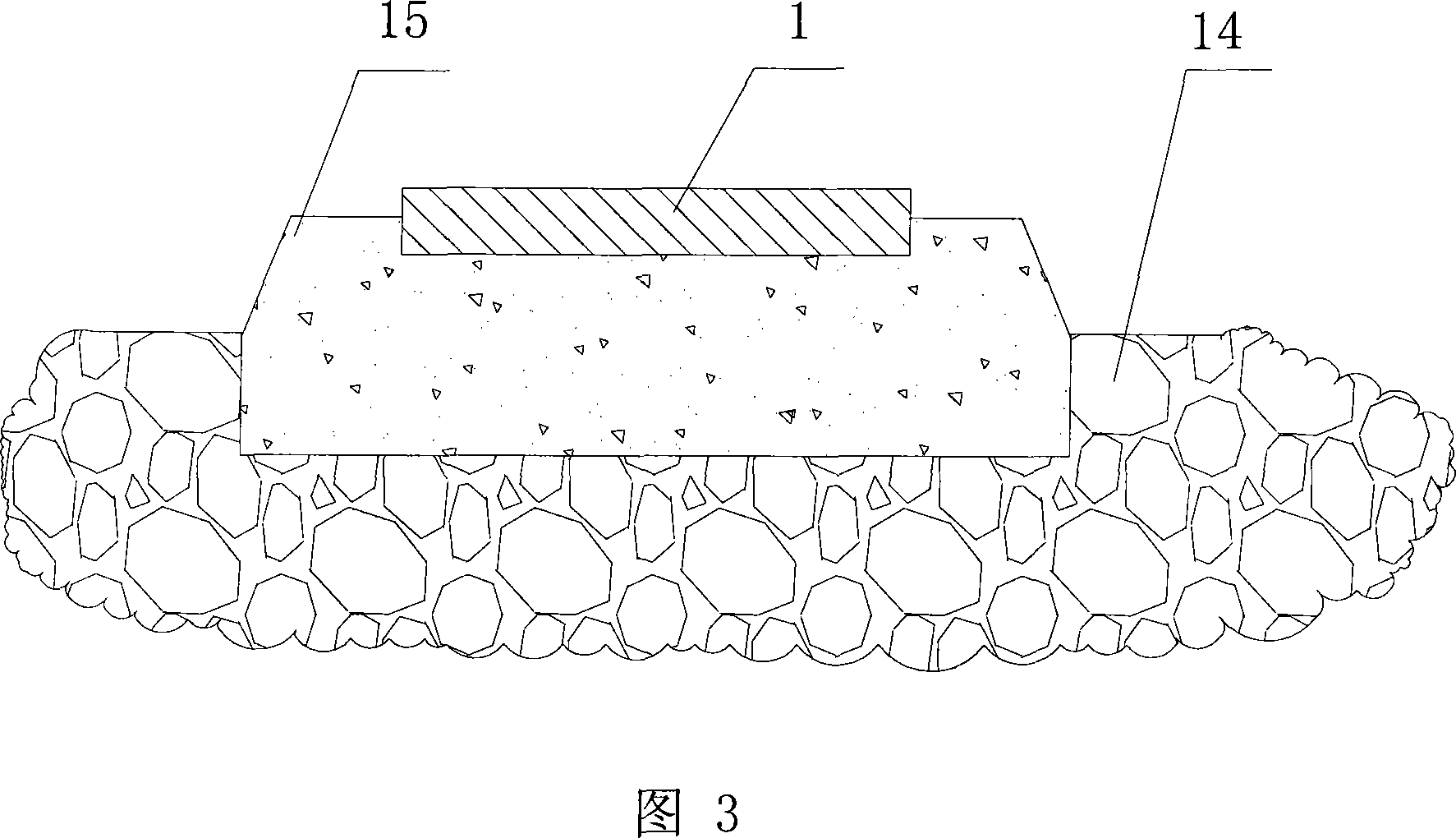

[0017] As shown in Figure 1 and Figure 2, the installation method of the backing plate in the construction of the grouting method includes the following steps:

[0018] 1) The backing plate 1 is welded with the first steel plate 2, the second steel plate 5, and the third steel plate 8 (the first steel plate 2, the second steel plate 5, and the third steel plate 8 are arranged in a triangle) with bolts passing through holes respectively, and the After the first bolt 3, the second bolt 7, and the third bolt 9 (respectively M10×40~50mm bolts) are respectively screwed on the corresponding first adjusting nut 11, the second adjusting nut 12, and the third adjusting nut, respectively thread Through the bolt holes on the first steel plate 2, the second steel plate 5, and the third steel plate 8, the upper ends of the first bolt 3, the second bolt 7, and the third bolt 9 above the backing plate 1 are respectively screwed on the corresponding The first fastening nut 4, the second faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com