Production method of biodegradable plastic bag

A production method and biodegradation technology, applied in the field of plastic bag production, can solve the problems of affecting normal use, deflection of the opening of the vest bag, lifting of the vest bag, etc.

Active Publication Date: 2022-06-21

浙江天济新材料科技有限公司

View PDF23 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. In the process of punching the vest bag, the hole and the surface are punched synchronously. When the number of punched vest bags is large at one time, when the upper vest bag is punched, even if the upper part is pressed, The plastic bag in the middle will still slide relative to each other, causing the opening of the punched vest bag to be deflected, affecting normal use;

2. After the punching of the vest bag, because the punching knife and the punching mechanism are separated from the vest bag after punching synchronously, the punching knife and the punching mechanism are easy to lift up the neatly arranged vest bags, which need to be rearranged later

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

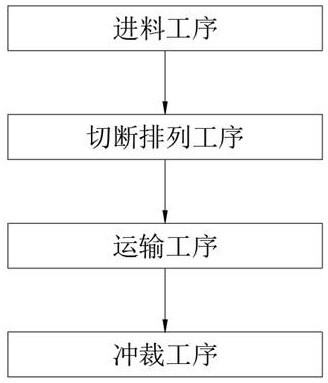

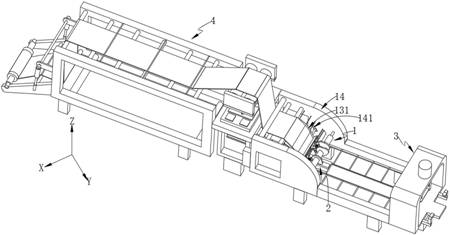

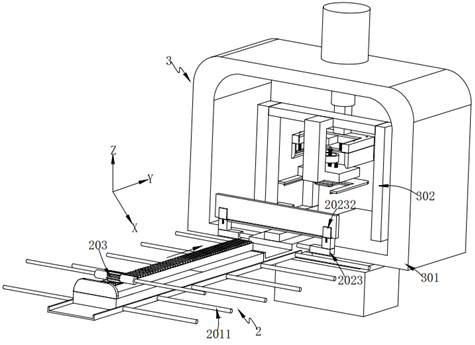

Login to View More Abstract

The invention provides a production method of a biodegradable plastic bag. The production method comprises the following steps: step 1, feeding; step 2, cutting and arranging; step 3, a transportation process; and 4, a blanking procedure is carried out, in the process that the material conveying unit enters the blanking unit, the pushing and rotating mechanism turns over the material clamping mechanism till the vest bag face is parallel to the plane where a blanking table is located, then a pre-pressing assembly moves downwards to pre-press the vest bag, punching work is carried out through a punching needle, and finally face cutting is carried out through a cut-off knife. According to the invention, after punching, the punching needle is still in the stacked vest pocket, and pre-positioning is carried out for the edge cutting procedure, so that the defect that when the edge of the thicker stacked vest pocket is cut, positioning is carried out only by adopting an upper end extrusion mode, the vest pocket stacked in the middle slides relatively, and large deviation occurs in the edge cutting process is overcome.

Description

technical field [0001] The invention relates to the technical field of plastic bag production, in particular to a method for producing a biodegradable plastic bag. Background technique [0002] Vest bags are essential items in daily life. In the process of placing vest bags, generally multiple sets of vest bags are stacked, and then placed by inserting the hole reserved at the opening of the vest bag into the hook for easy use. can be withdrawn at any time. [0003] Chinese patent CN 208197678 U discloses a cutting device for plastic bags, including a base, the left side of the upper surface of the base is fixedly connected with a left bracket, the upper surface of the base is provided with a groove, and the inside of the groove is placed There is a right bracket, the left side of the right bracket is provided with two symmetrical through holes, the inner side wall of the groove is fixedly connected with two symmetrical slide bars, and the left side of the right bracket is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B31B70/00B31B70/20B31B70/04B31B70/02B31B70/74B31B70/98

CPCB31B70/005B31B70/142B31B70/20B31B70/04B31B70/022B31B70/74B31B70/98

Inventor 都智刚李成林

Owner 浙江天济新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com