Method and device for handling tyres

A control device and tire technology, which is applied in the field of tire control devices to achieve the effect of reducing the manipulating time, reducing the tire production time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

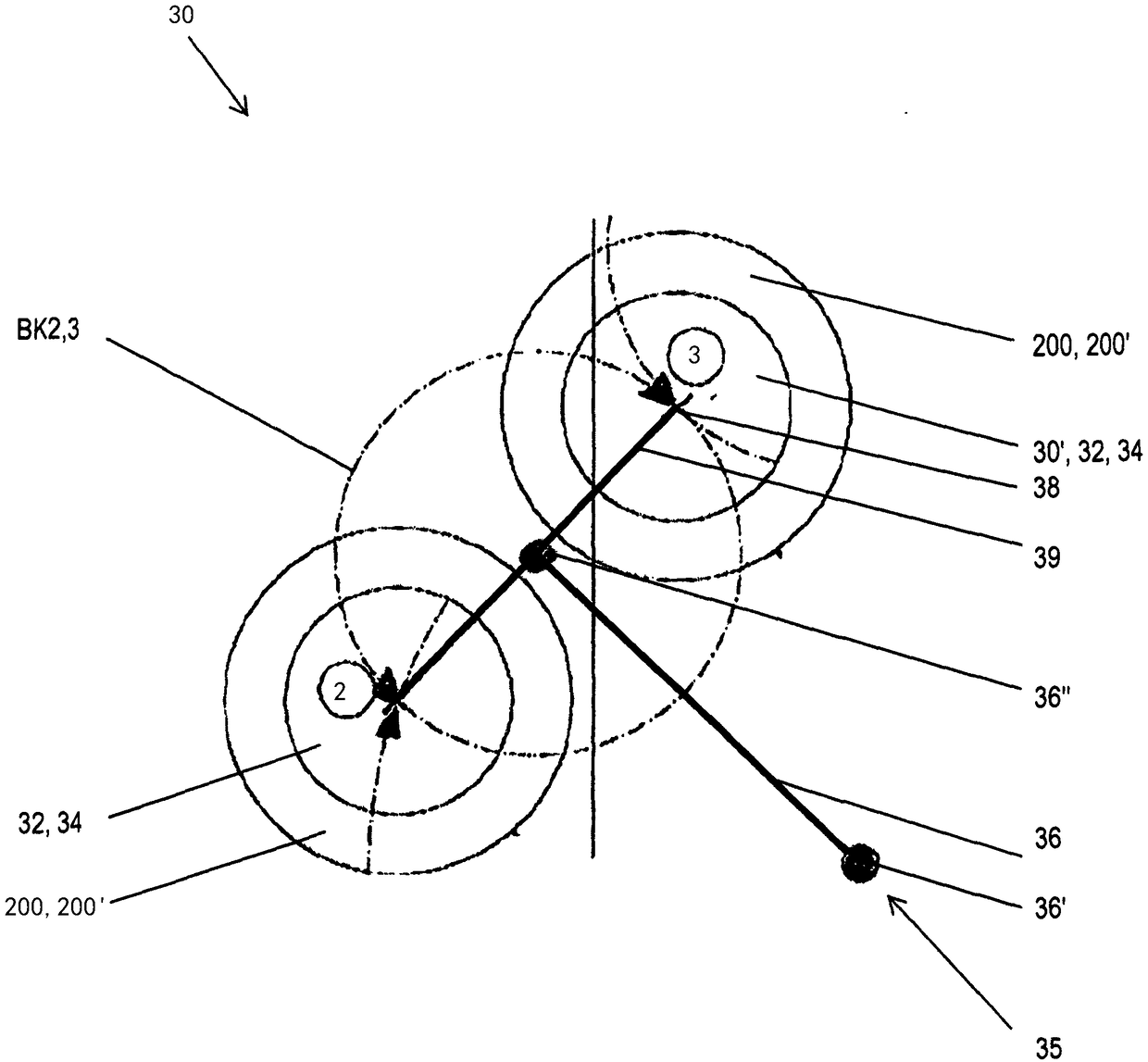

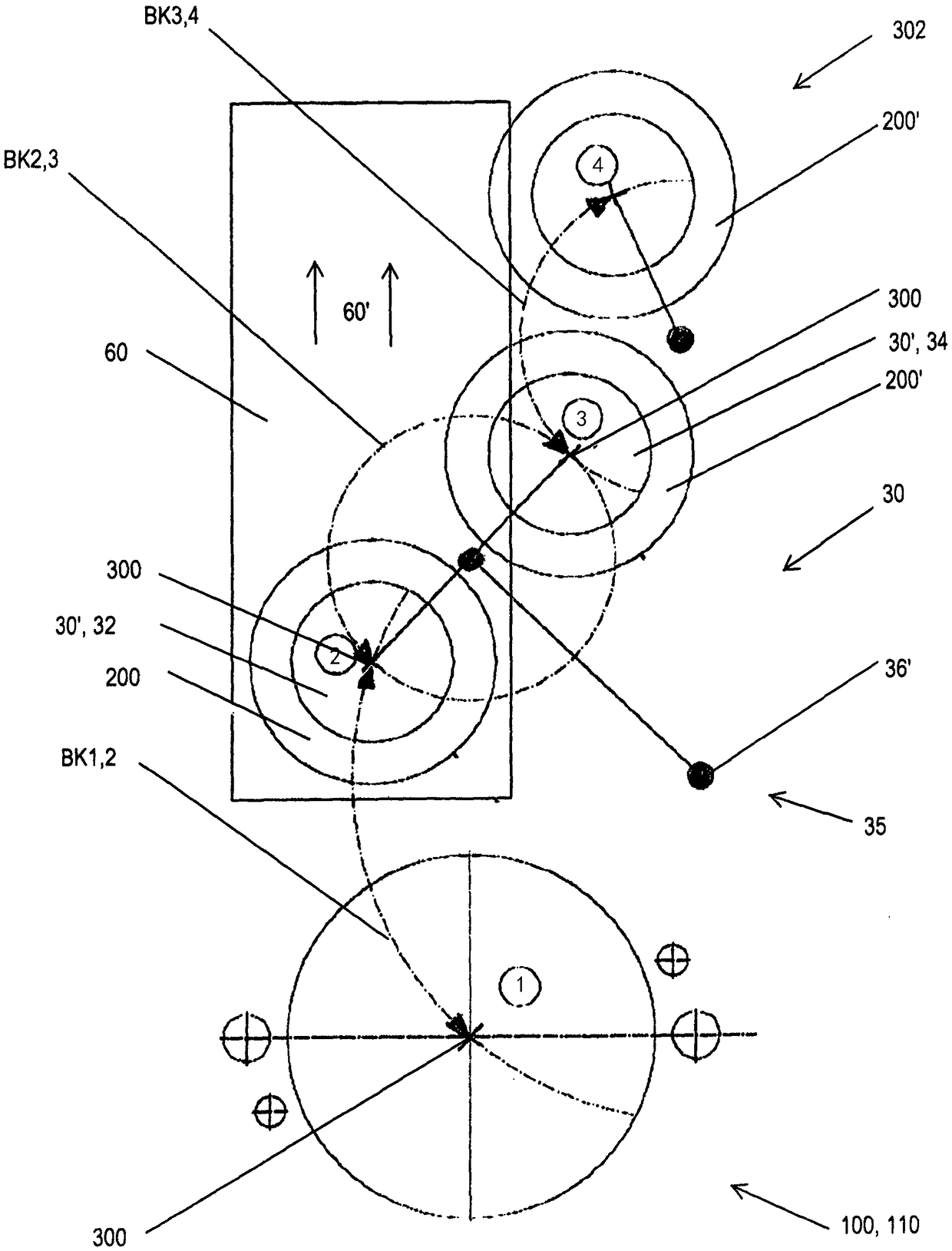

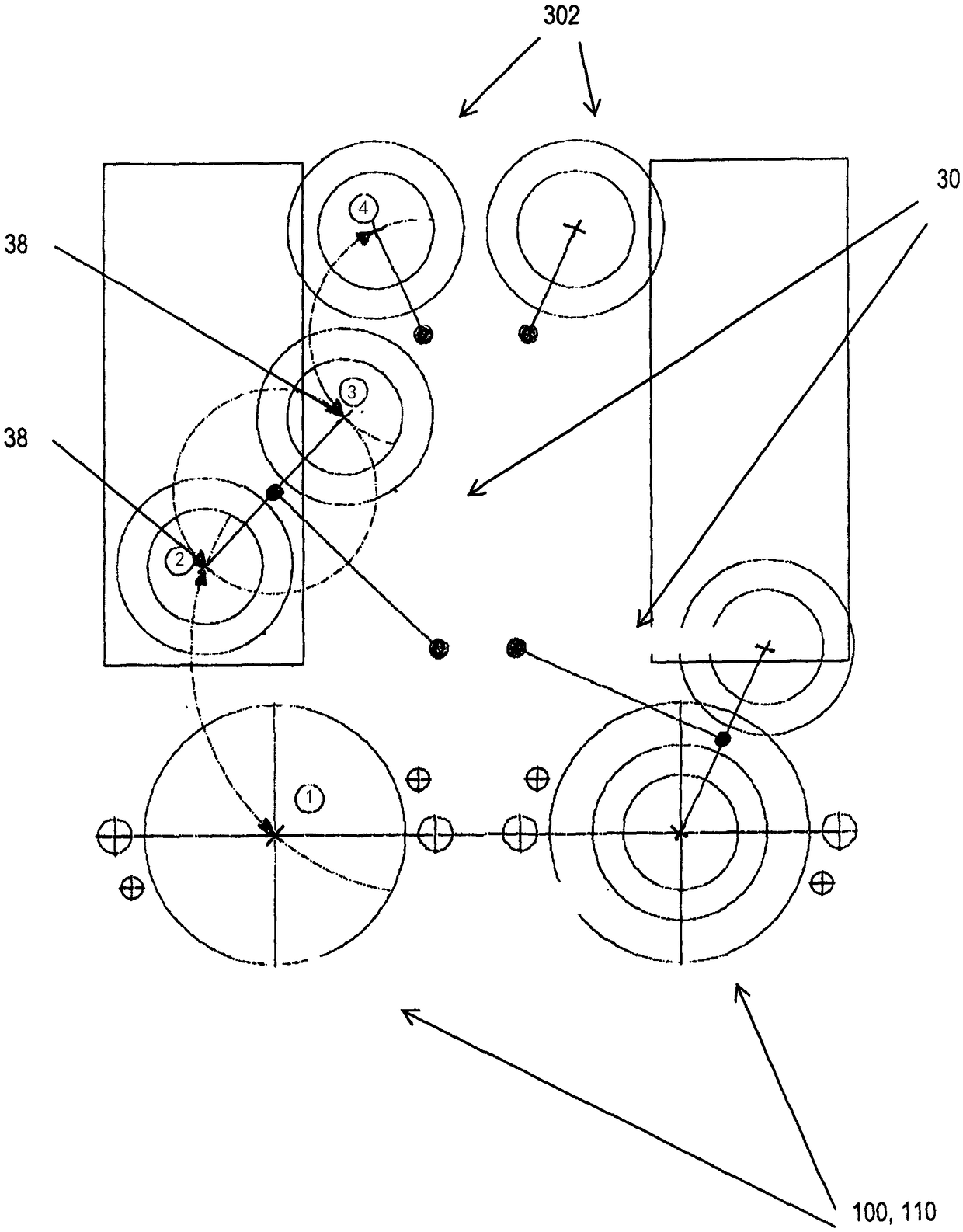

[0042] figure 1 is a schematic plan view of the manipulation device 30 as a highly simplified schematic diagram. At least one extension arm 36 is coupled to or supported at the receiving member 35 through a first extension arm pivot location 36'. The receiving member 35 can be configured as a base 35' and can have preferably linear degrees of freedom so that different operating planes can be accessed. For example, a sliding member 35" may provide this linear degree of freedom - the sliding member 35" and base 35' are not shown.

[0043] A first extension arm pivot location 36 ′ provided on the end side of the extension arm 36 preferably supports a pivoting movement about a vertical axis and thus enables the extension arm 36 to pivot in a horizontal plane. The pivot movement kinematics centered relative to the first extension arm pivot position 36' preferably follows a circular shape and thus a pivot path of up to 360 degrees is possible. However, due to the spatial relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com