Automobile brake floor production line capable of effectively controlling processing quality and its working method

A technology of automobile braking and processing quality, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of excessive labor intensity, manual processing, and low product qualification rate, and achieve flexible and fast control of time. Take the effect of controlling high efficiency and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

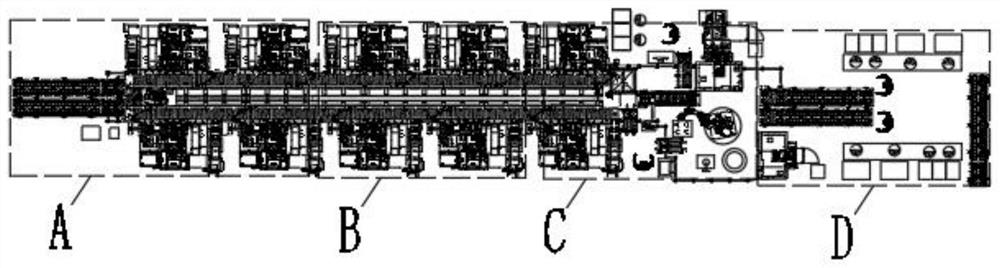

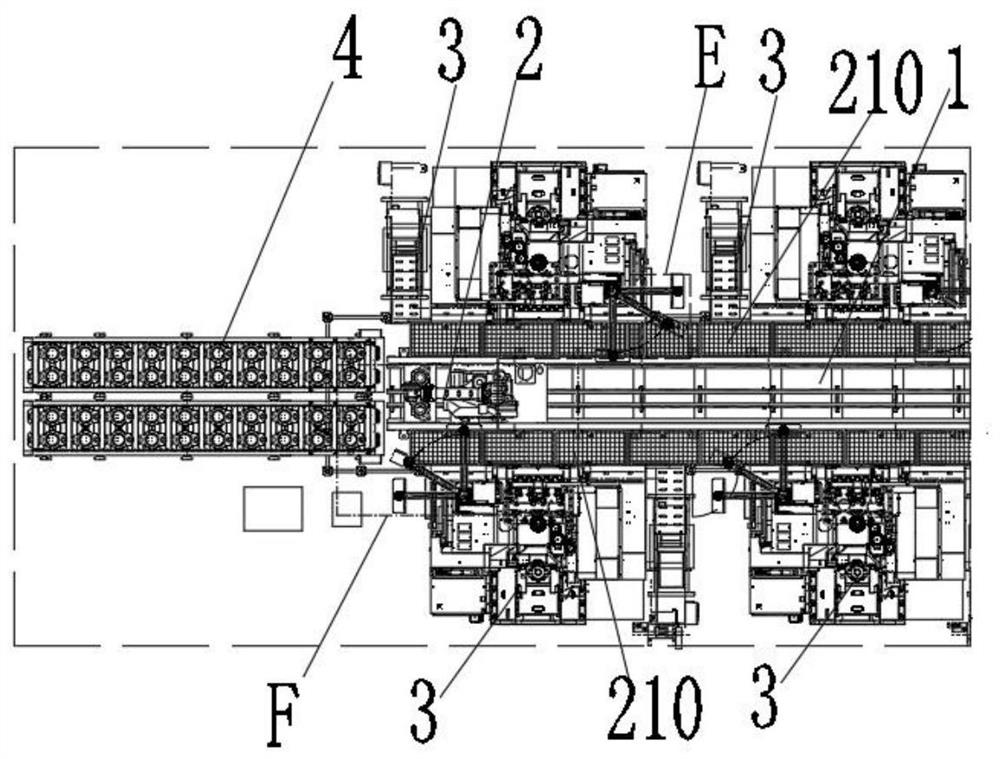

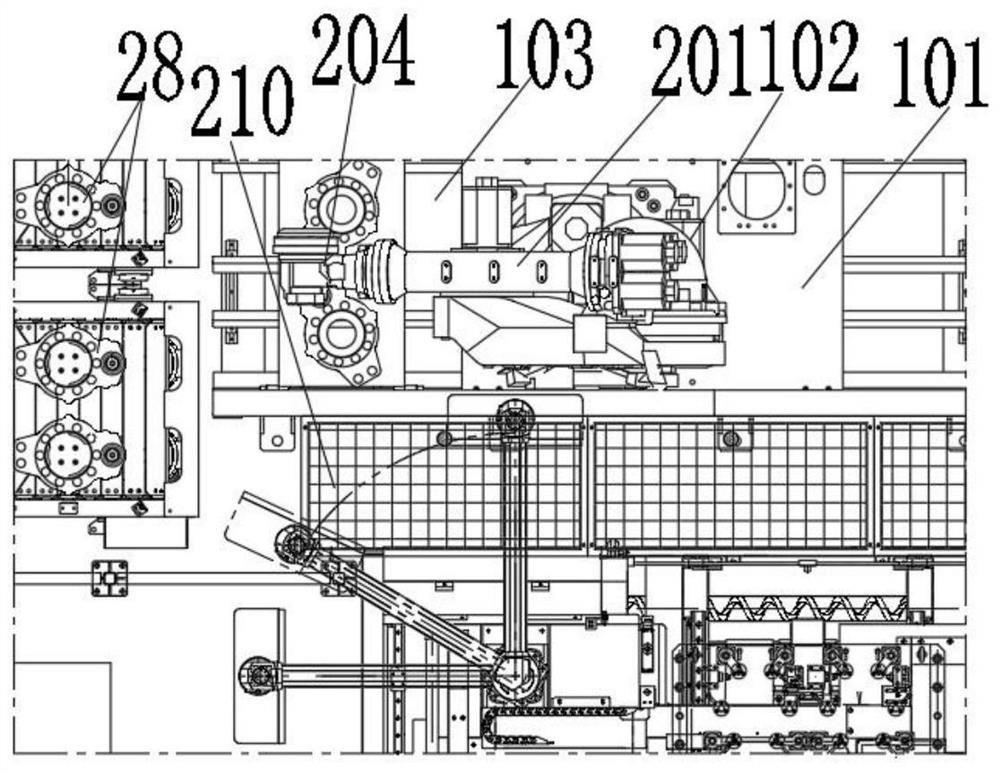

[0026] Example 1. like Figure 1-33 As shown, the automobile brake floor production line that can effectively control the processing quality is characterized in that: the production line includes a horizontally arranged robot walking track 1, a first grabbing mechanism 2, a number of CNC grinding machine tools 3, a feeding conveyor belt 4, Automobile brake bottom plate turning table 5, second grabbing mechanism 6, transfer conveyor belt 22, pneumatic debris cleaning table 23, detection turnover table 24, two drilling and tapping CNC machine tools 7, cutting fluid filter plate 8, weighing Disk 9, first coding machine 10, second coding machine 11, transition conveyor belt 12, discharge conveyor belt 13, first manual grinding turntable 14, control center 15, second manual grinding turntable 16, detection and analysis Labeling table 17, manual grinding tooling 18, two manual processing tooling 19, buffer table 20, computer 21. The robot walking ground rail 1 is provided with a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com