Dual-airy-beam systems and methods for processing glass substrates

A glass substrate, beam angle technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as difficulty in using laser beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

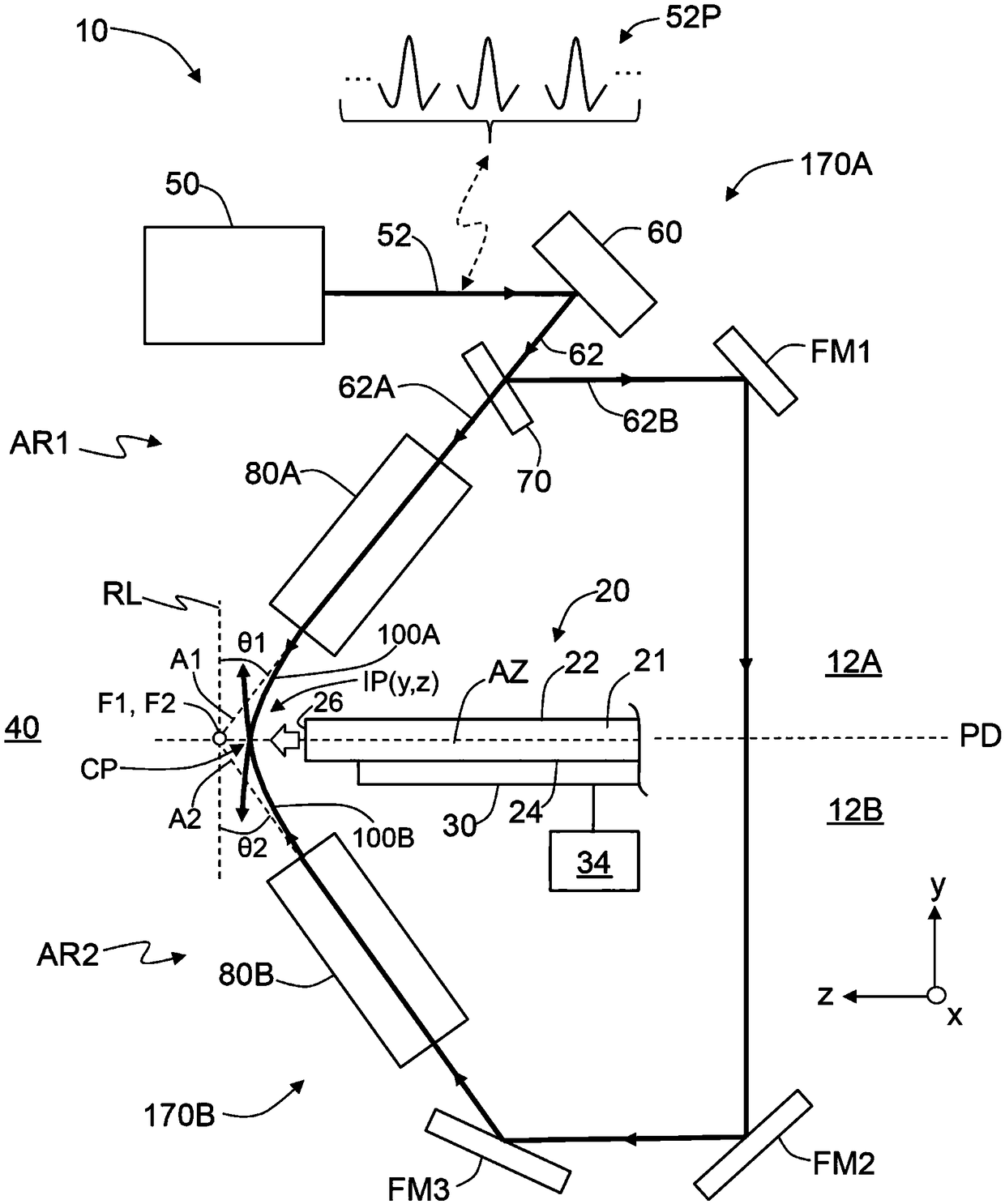

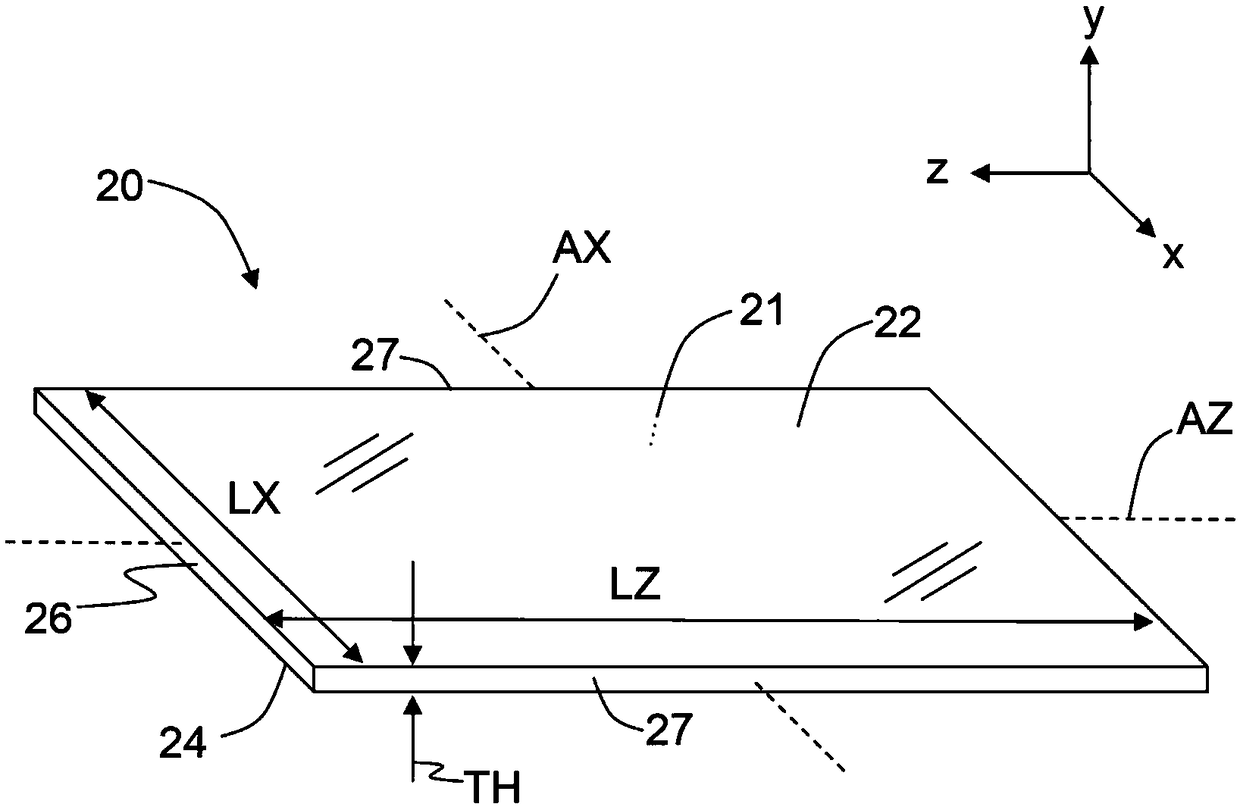

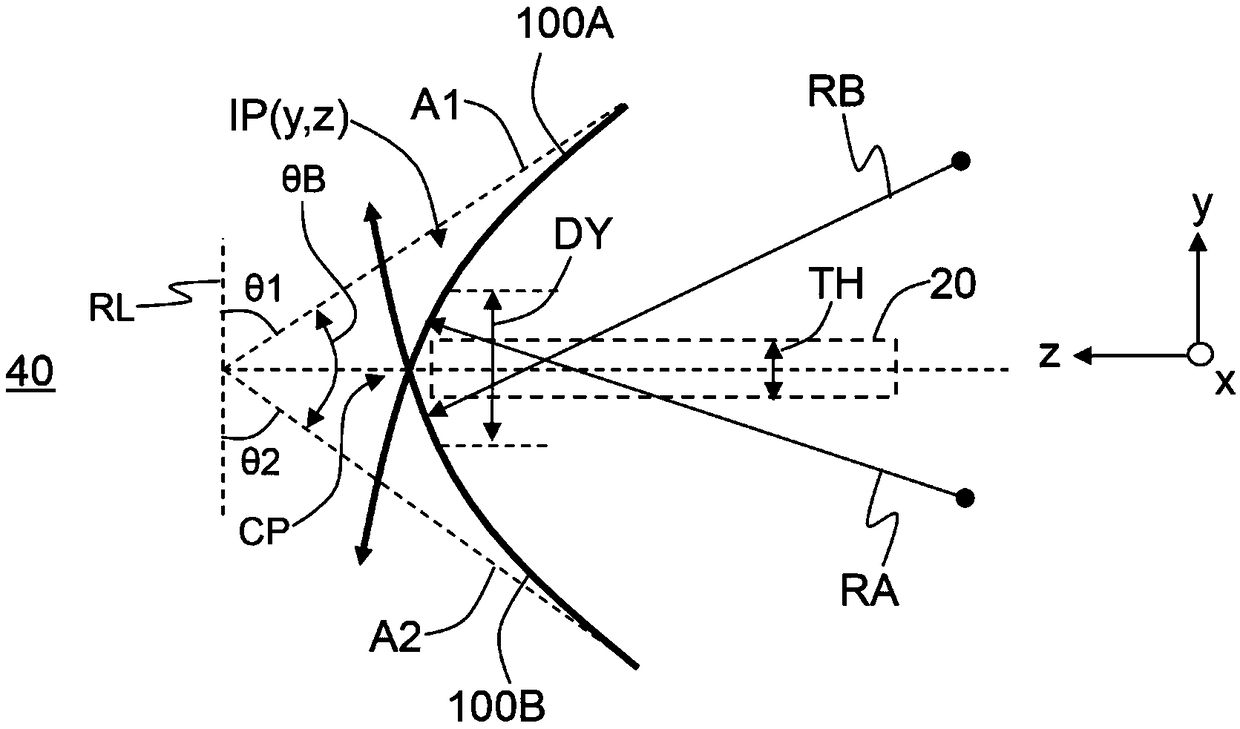

[0024] Reference will now be made in detail to the various embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings. Wherever possible, the same or similar reference numbers are used throughout the drawings to refer to the same or similar parts. The drawings are not necessarily drawn to scale; those skilled in the art will appreciate that the drawings have been simplified to illustrate key aspects of the disclosure.

[0025] The claims set forth below are hereby incorporated into and constitute a part of this Detailed Description.

[0026] For ease of reference, Cartesian coordinates are shown in some of the figures; Cartesian coordinates are not intended to be limitations with respect to direction or orientation.

[0027] The complete disclosures of any publications or patent documents mentioned herein are incorporated herein by reference, including the following:

[0028] Berry et al., "Nonspreading wave packets", Am. J. Phys., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com