Horizontal formwork

A formwork and horizontal technology, applied in the direction of formwork/formwork/work frame, connectors and pillars of formwork/formwork/work frame, etc., can solve the problem of reduced system flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

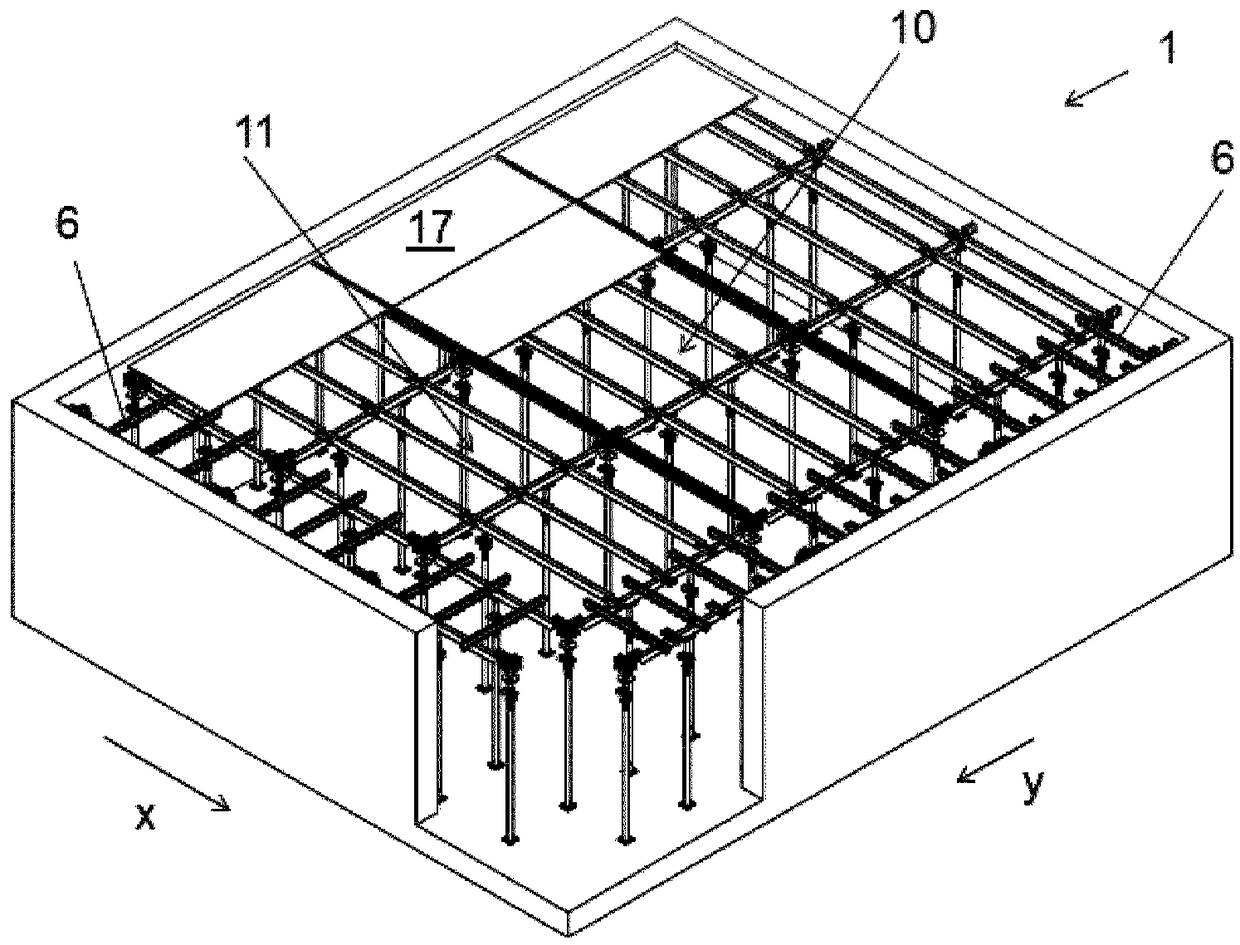

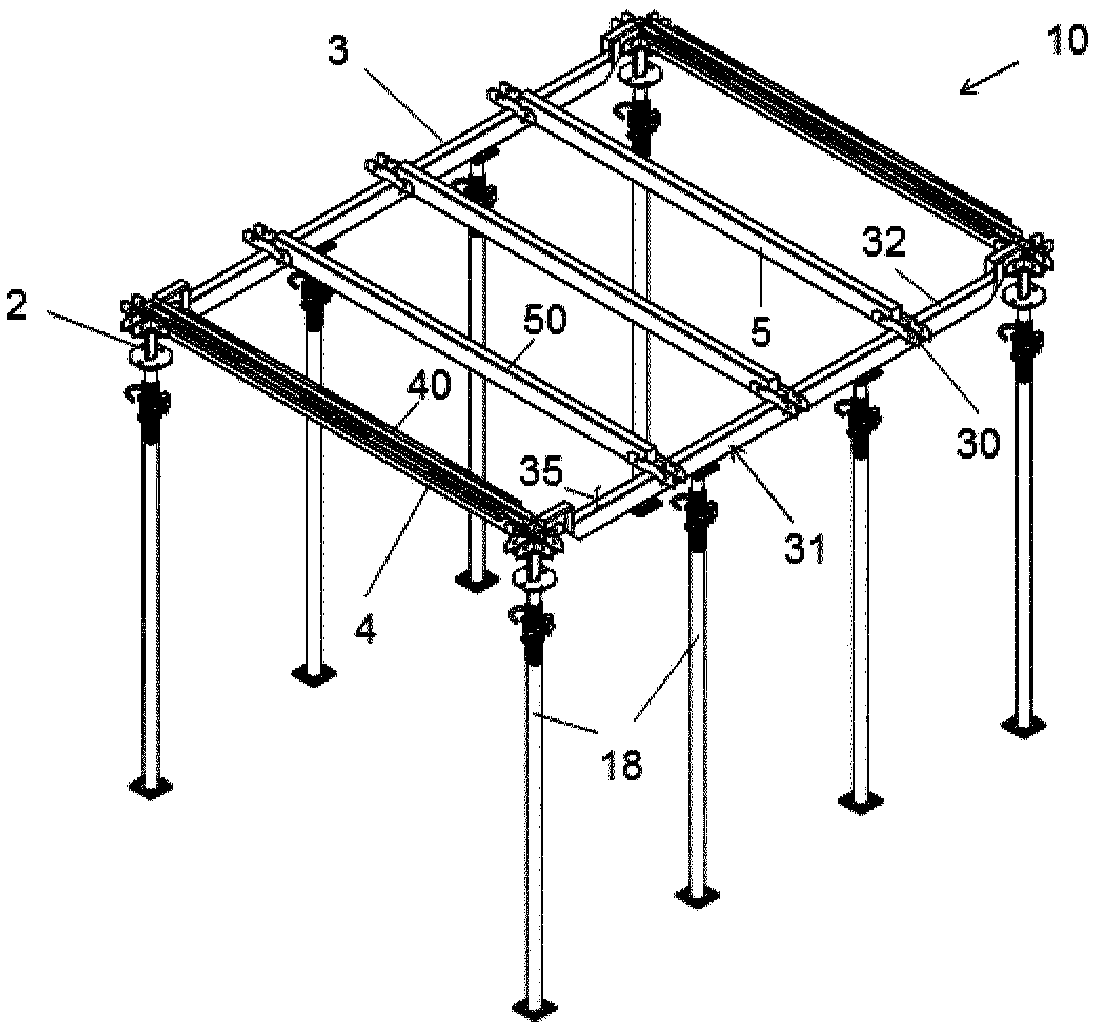

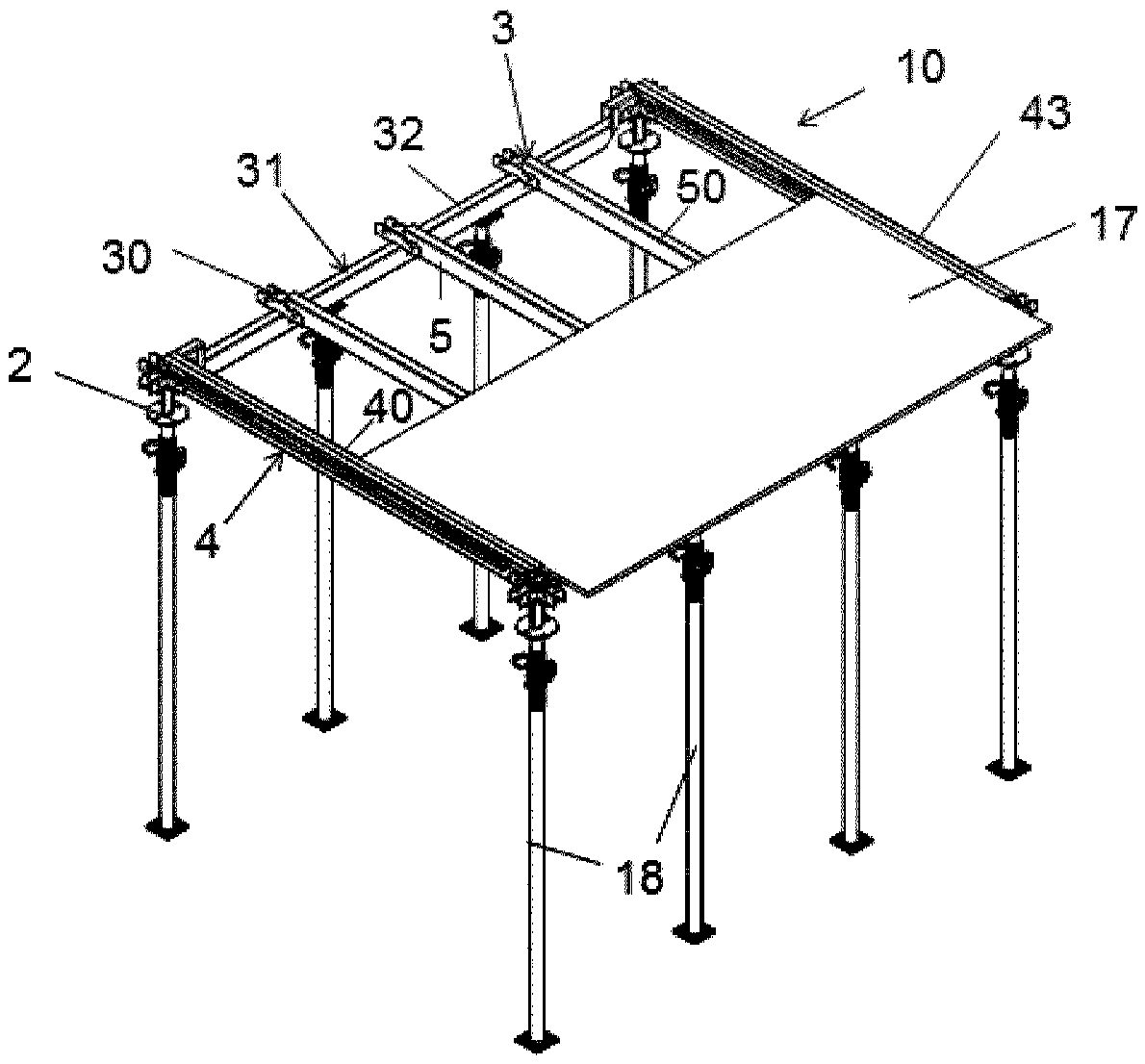

[0037] The horizontal formwork 1 according to the invention comprises a supporting base and a plurality of formwork panels 17 supported on said supporting base. The supporting base comprises a plurality of elementary grids 10 .

[0038] The basic grid 10 forms a modular formwork. Furthermore, the horizontal formwork 1 according to the invention may comprise extensions of the support base both in the longitudinal direction and in the transverse direction, making said support base suitable for example as figure 1 The wall trimming shown in the implementation.

[0039] For the purposes of understanding this description, the longitudinal direction will be considered to be the direction perpendicular to the main beam 3, i.e., figure 1 The direction indicated by "x" in , while the transverse direction will be considered as the direction parallel to the main girder 3, i.e., figure 1 The direction indicated by "y" in .

[0040] The horizontal formwork 1 according to the invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com