Compressor and heat cycle system

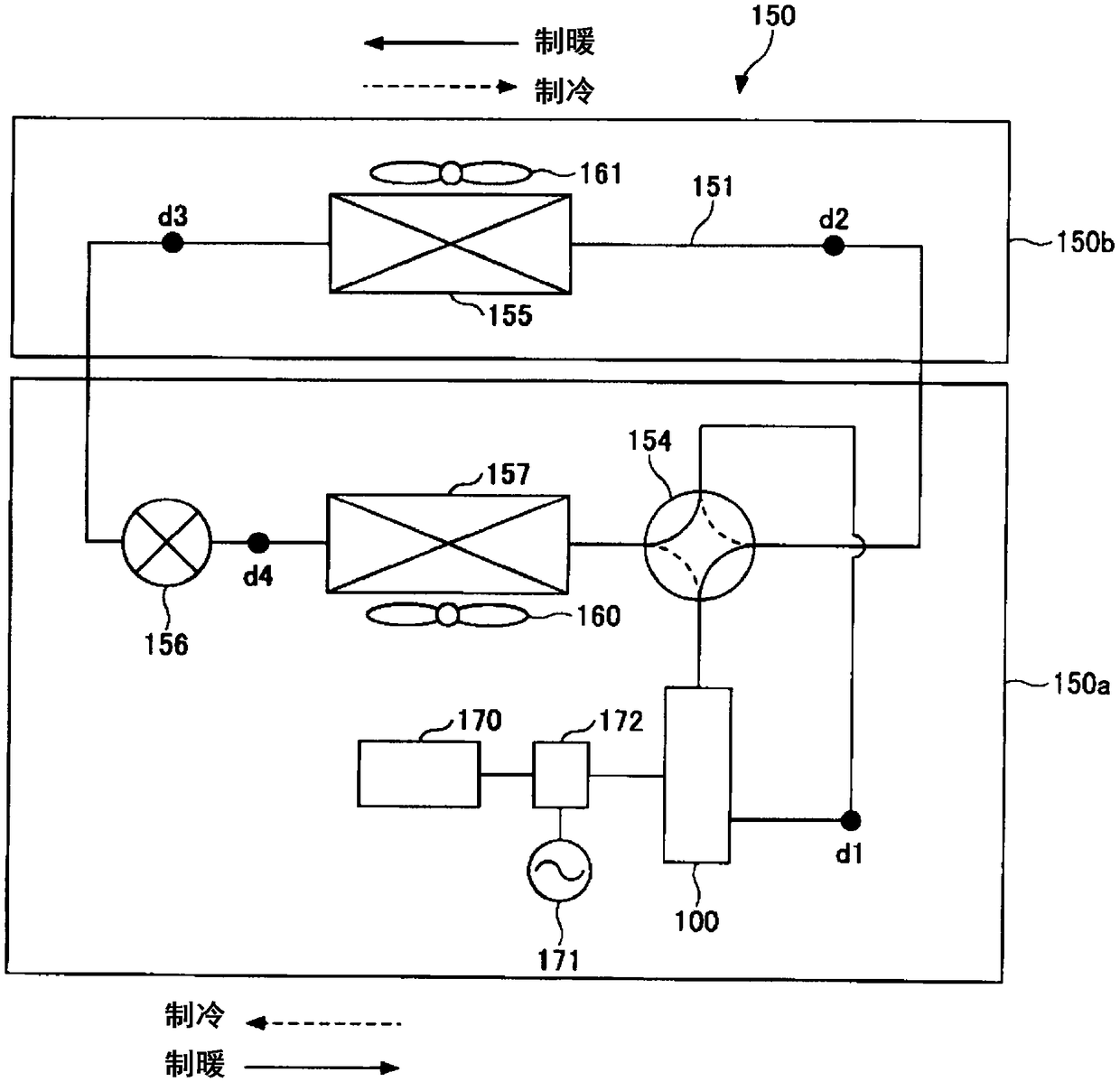

一种压缩机、压缩部的技术,应用在压缩机、照明和加热设备、制冷机等方向,达到防止自分解反应、防止火花的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

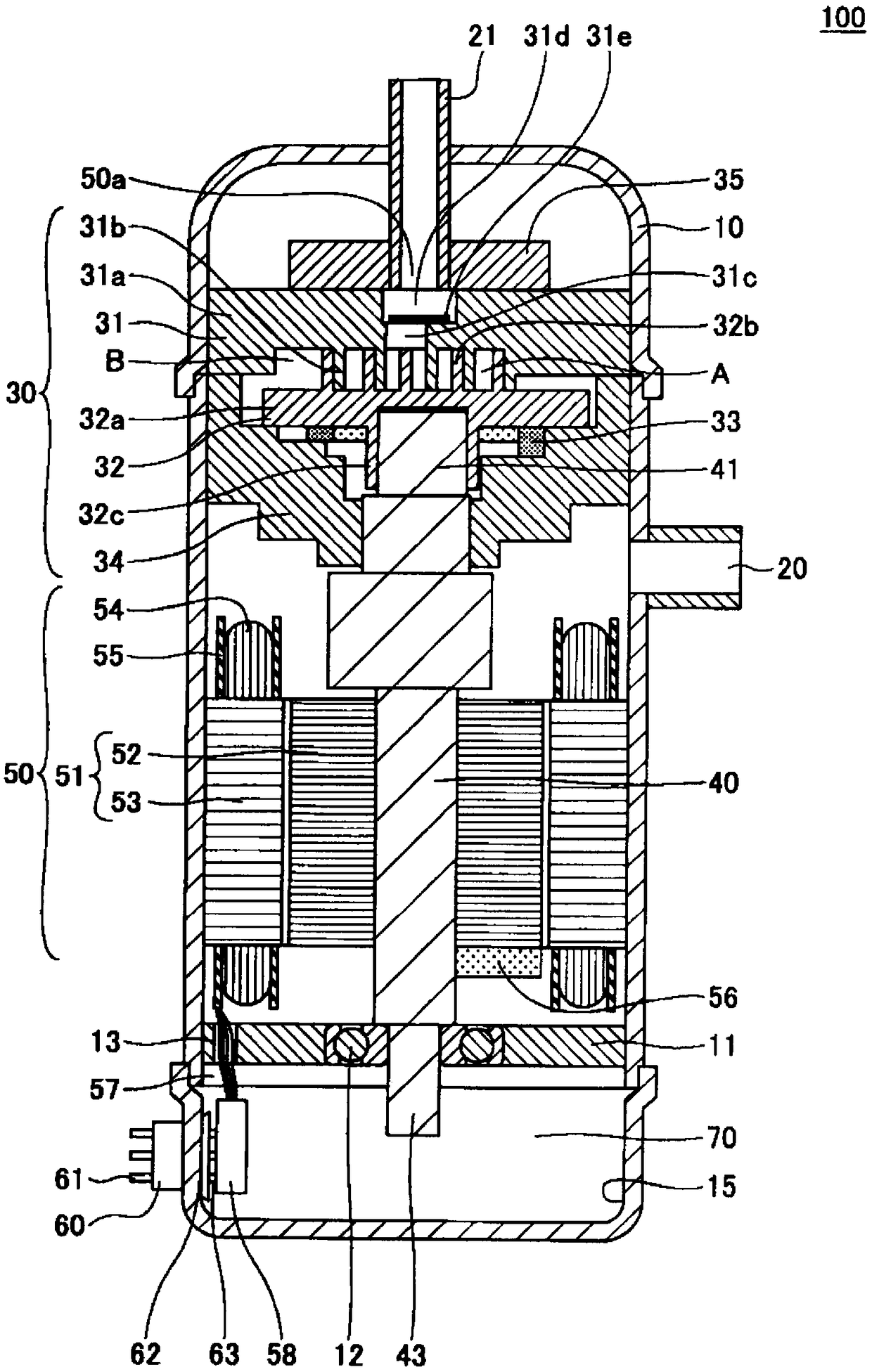

[0032] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings.

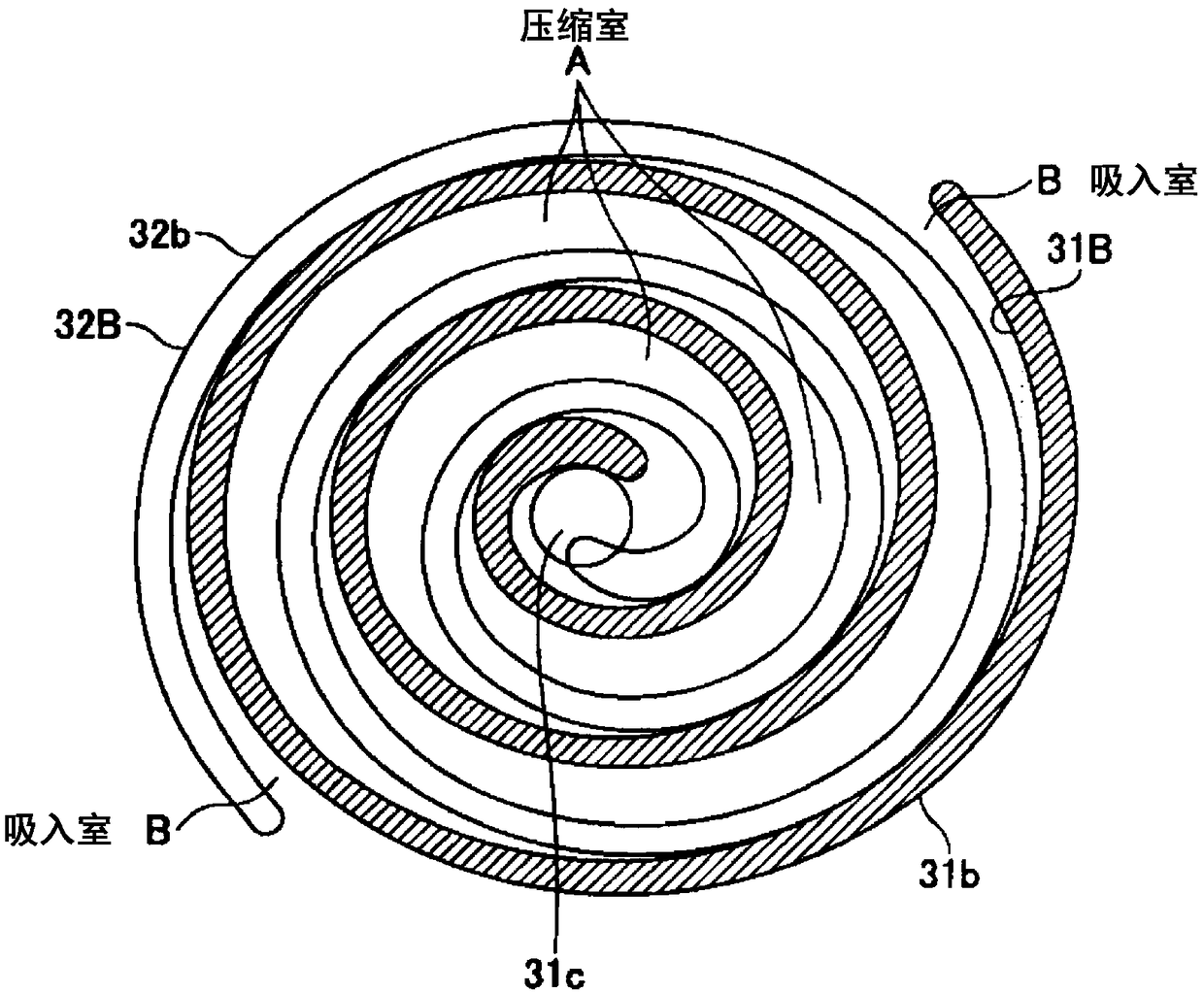

[0033] figure 1 It is a sectional view showing the configuration of an example of the compressor 100 according to the embodiment of the present invention. The compressor of the present invention can use various types of compressors including scroll compressors and rotary compressors as long as the compression part is arranged above and the electric part is arranged below. A type compressor will be described as an example of the compressor of the present invention.

[0034] The compressor 100 includes an airtight container 10 , a suction pipe 20 , a discharge pipe 21 , a compression unit 30 , a shaft 40 , an electric unit 50 , and a power supply terminal 60 .

[0035] The airtight container 10 functions as a casing of the compressor 100 and accommodates the compression unit 30 , the shaft 40 , the electric unit 50 , the power supply terminal 60 and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com