Cabinet with high storage performance

A storage and cabinet technology, which is applied in the field of high storage cabinets, can solve problems such as wall damage, door frames that cannot be completely closed, and methods that are not reliable enough to improve storage and storage functions, improve storage and storage performance, and increase storage space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

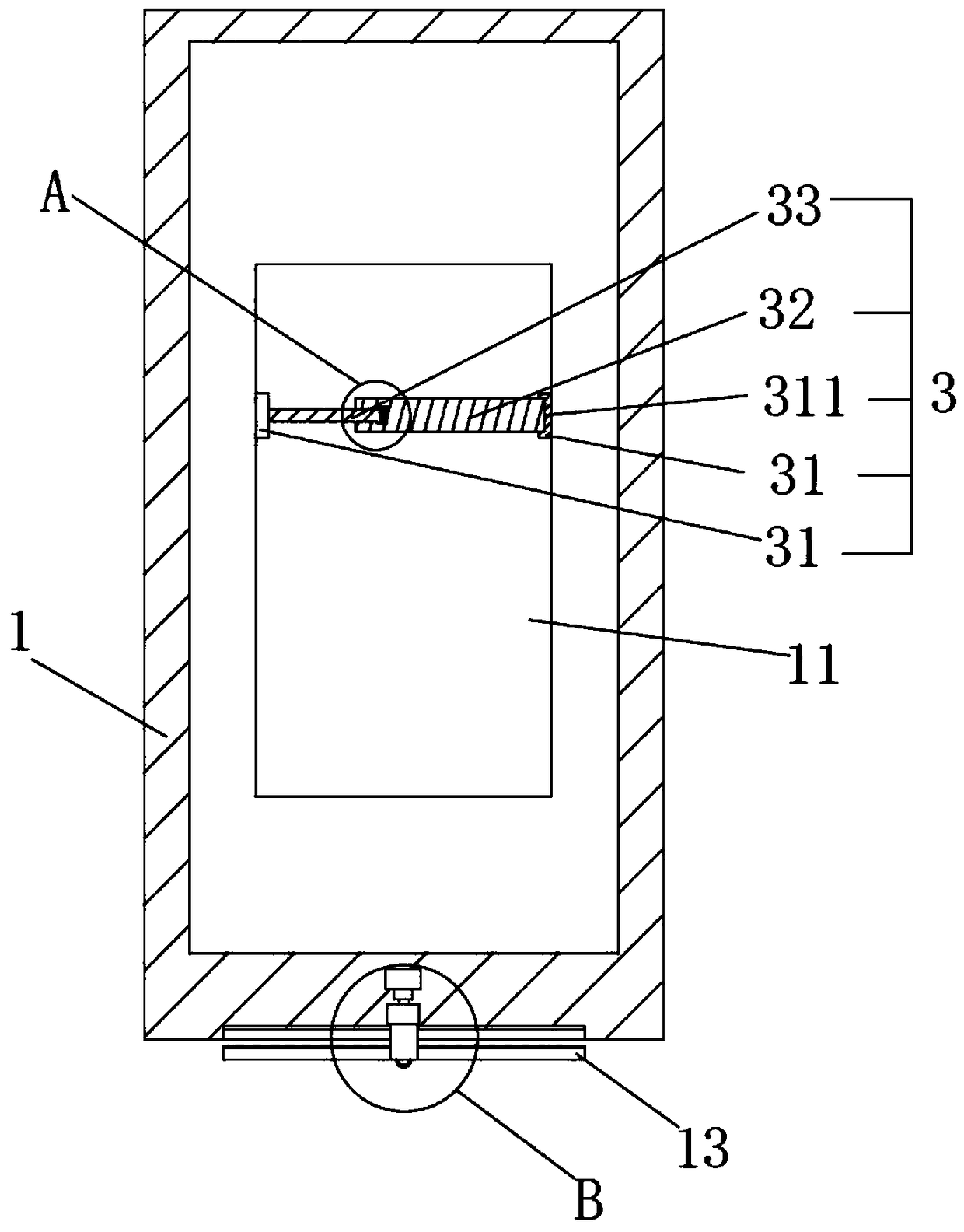

[0052] Embodiment 1: A cabinet with high storage capacity, such as figure 1 with 2 Shown, comprise cabinet body 1, be provided with switch door (not shown in the figure) on cabinet body 1, to realize the closing of cabinet body 1, be provided with track groove 11 on the opposite side with switch door in cabinet body 1, track groove 11 is provided with an internal storage frame 2 for sliding, and an electromagnet one is arranged in the internal storage frame 2, and an electromagnet two (not shown) that is adsorbed with the electromagnet one is arranged in the cabinet body 1. By starting the electromagnet one and The electromagnet 2 can fix the position at any position when the internal storage frame 2 slides downhill in the cabinet 1.

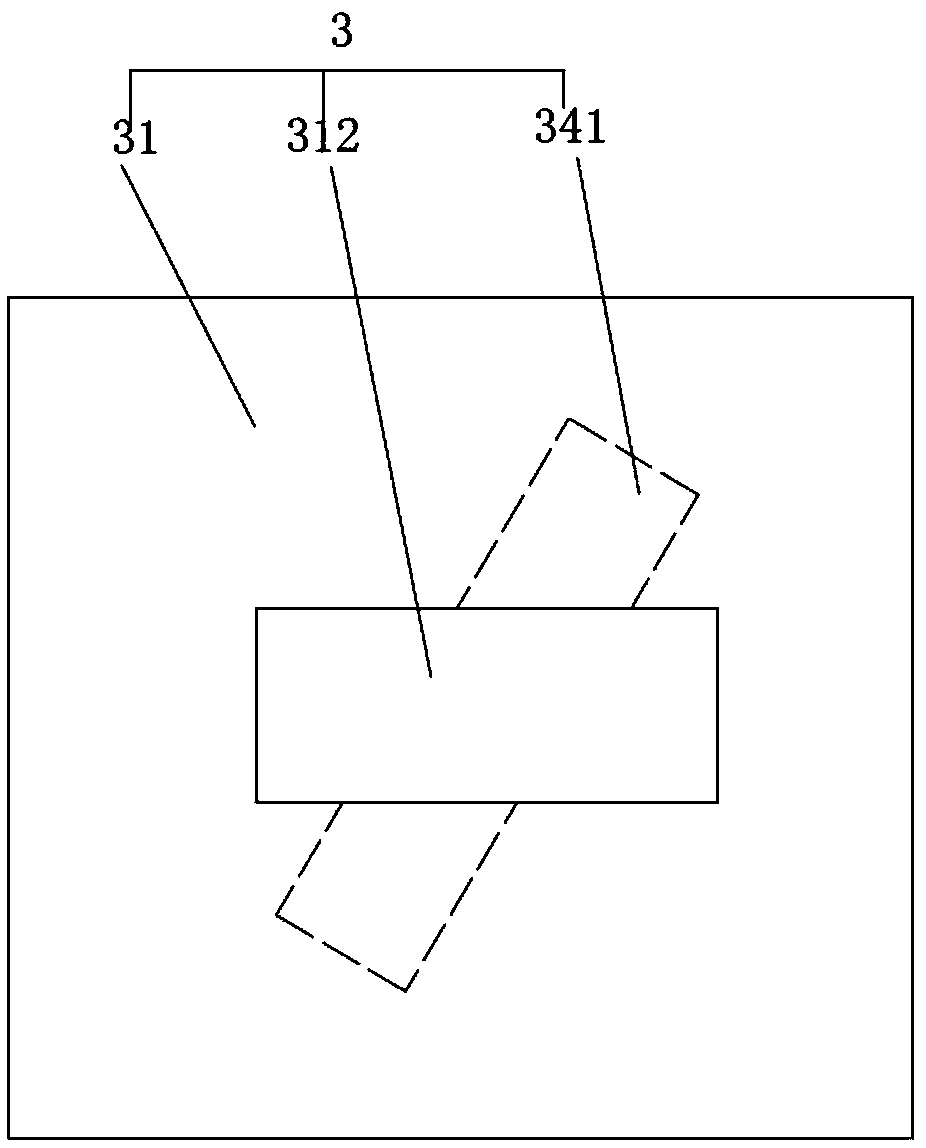

[0053] Such as figure 1 , 3 , 4 and 5, the internal storage frame 2 realizes the sliding connection in the track groove 11 through the detachable connection mechanism 3, and the detachable connection mechanism 3 includes a pair of sliding buc...

Embodiment 2

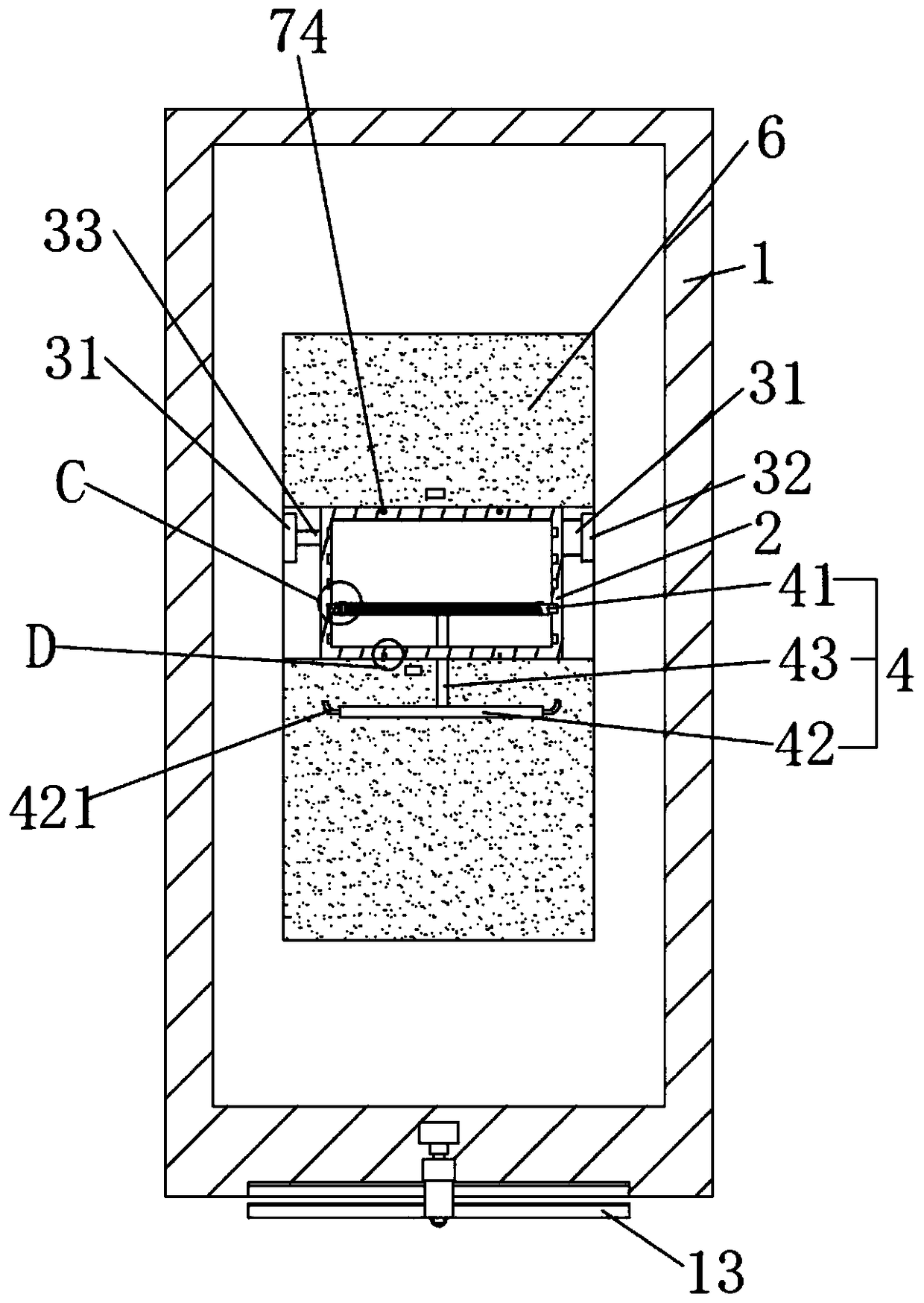

[0064] Embodiment 2: A cabinet with high storage capacity, the difference from Embodiment 1 is that, as figure 2 with 8 As shown, at this time, the upper and lower end surfaces of the internal storage frame 2 are provided with shutters 6 through the connecting mechanism 7, and the shutters 6 are all slidably connected in the cabinet body 1, and the connecting mechanism 7 includes the inner storage frame. 2 The square slots 71 on the upper and lower end surfaces, the two shutters 6 are fixedly equipped with a connecting block 72 embedded in the storage slot 12, and the connecting block 72 is provided with a limit threaded hole 73, and the internal storage frame 2 is equipped with a connecting block 72. A limit nail 74 embedded in the limit threaded hole 73 is provided.

Embodiment 3

[0066] Embodiment 3: A cabinet with high storage capacity, the difference from Embodiment 1 is that, as Image 6 As shown, at this time, an upper rubber gasket 121 is fixedly arranged in the storage tank 12, and a lower rubber gasket 131 is fixedly arranged on the upper surface of the lifting plate 13, and the lower rubber gasket 131 extends the width direction array of the lower rubber gasket 131. Multiple arc-shaped limiting slots 132 are provided.

[0067] Specific embodiments: when the metal storage rack is placed on the lifting plate 13, the metal connecting rod 43 on the metal storage rack can be embedded in the arc-shaped limiting groove 132 to improve the limiting effect on the metal storage rack. Through the driving mechanism 14, the lifting plate 13 drives the metal storage rack to rise as a whole, and the connecting rod 43 of the metal storage rack conflicts with the upper rubber gasket 121 to further realize the position limiting effect on the metal storage rack. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com