Solid and liquid separation mechanism for kitchen

A dry and wet separation, kitchen technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of easy dumping, garbage and sewage can not be fully treated, ground pollution, etc., to achieve easy lubrication, wear and tear Light, pollution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

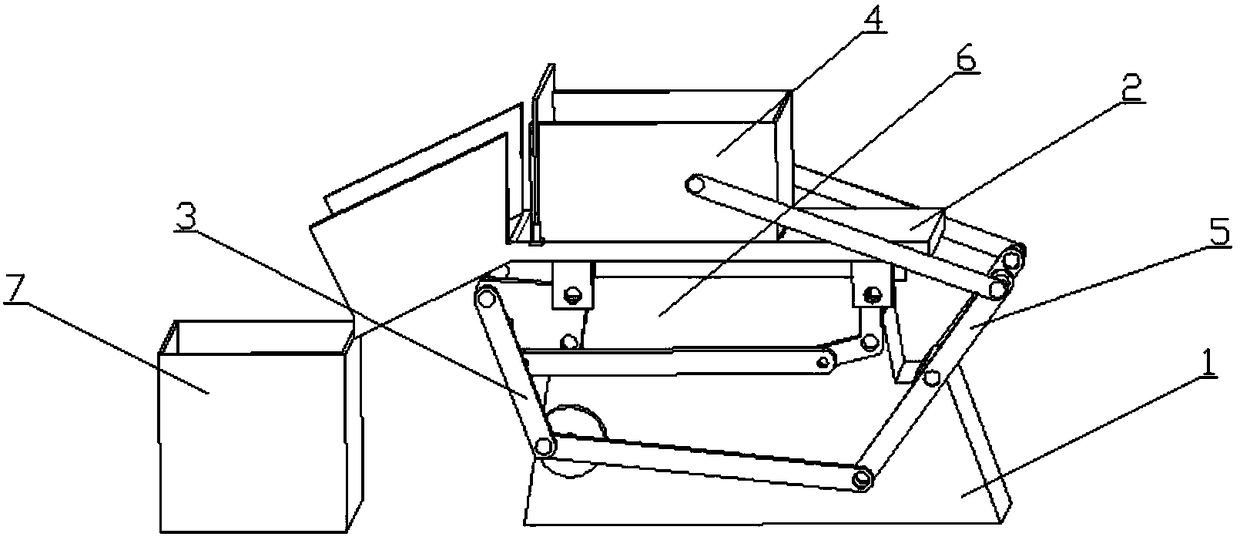

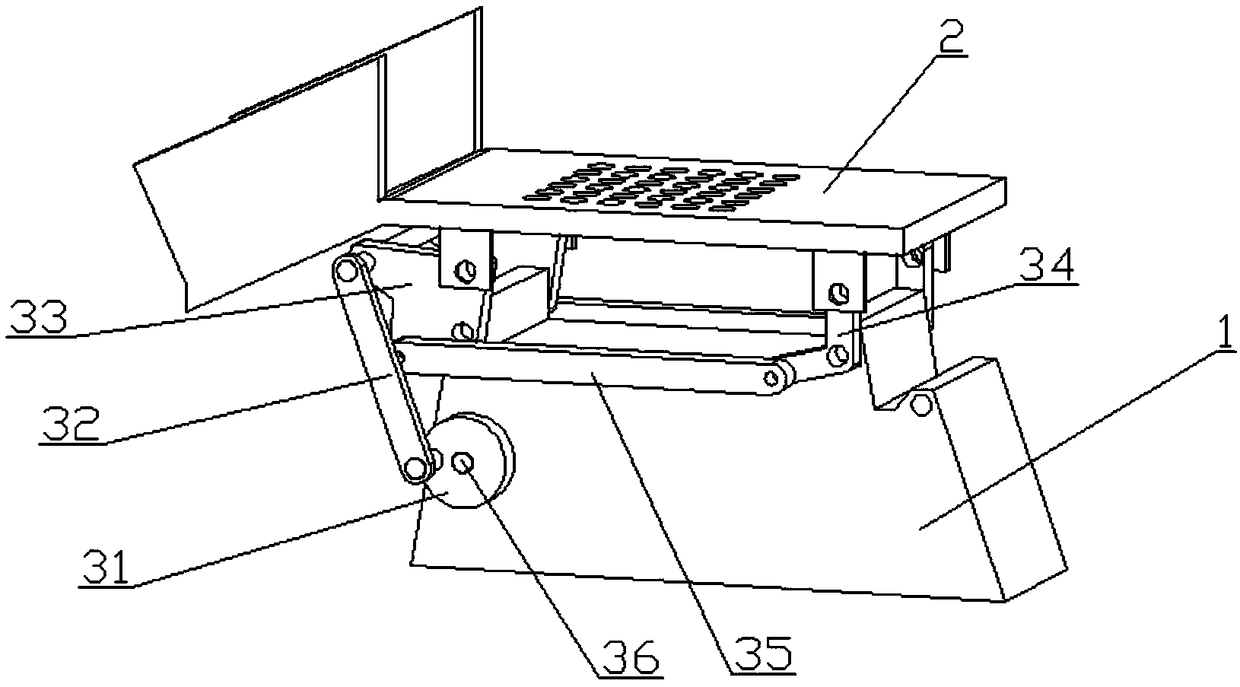

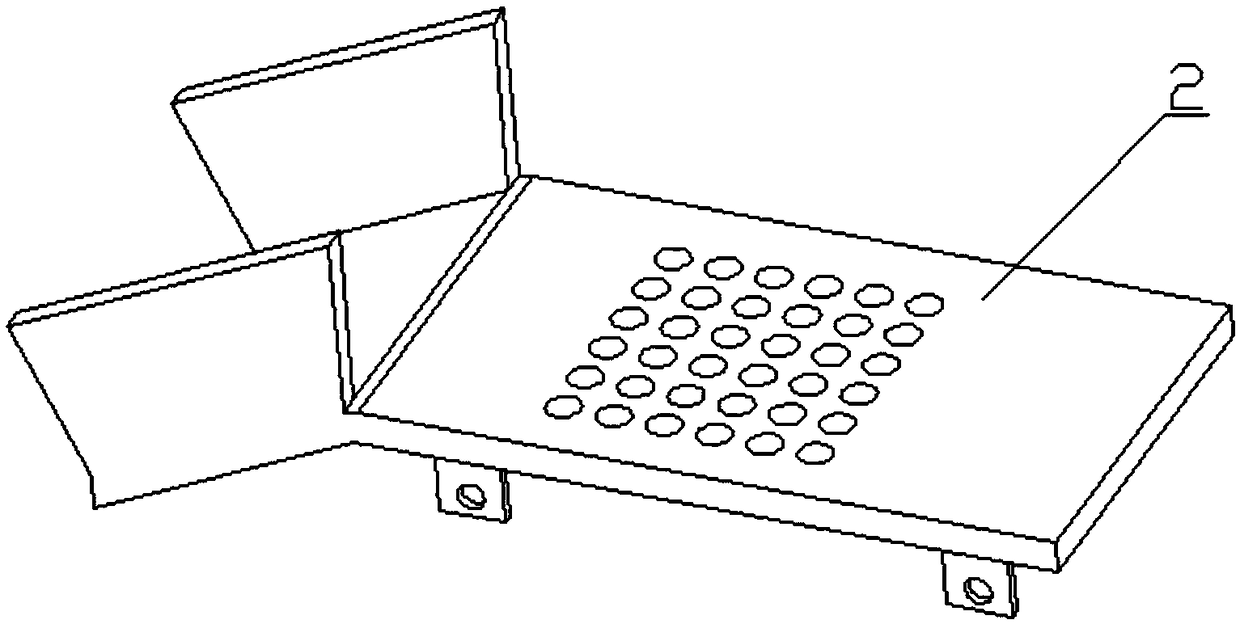

[0032] see Figure 1 to Figure 6 , the present invention is: a dry-wet separation mechanism for kitchen, including a base 1, a top plate 2 is arranged on the base 1, a crank connecting rod A3 is arranged between the top plate 2 and the base 1, and the crank connecting rod A3 drives the top plate 2 to move horizontally , a container 4 is arranged on the top plate 2, a crank connecting rod B5 is arranged between the container 4 and the base 1, and the crank connecting rod B5 drives the container 4 to reciprocate horizontally, the bottom of the container 4 is provided with a through hole A, and the top plate 2 is provided with a through hole B. A water tank 6 is arranged between the top board 2 and the base 1 , and a vegetable storage box 7 is arranged on one side of the base 1 , and the vegetable storage box 7 corresponds to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap