Loading and unloading mechanical arm of automatic dispensing production line

A technology of automatic dispensing and production line, which is applied to manipulators, devices that apply liquid to surfaces, coatings, etc. It can solve the problems of poor accuracy, expensive manipulators, and cumbersome structure, and achieve the effect of convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

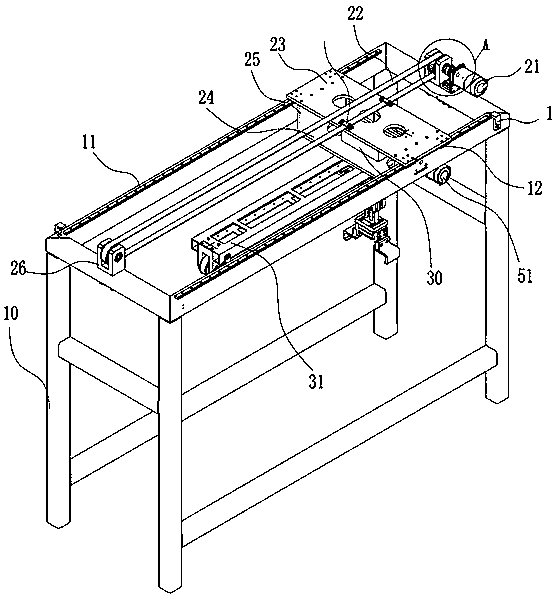

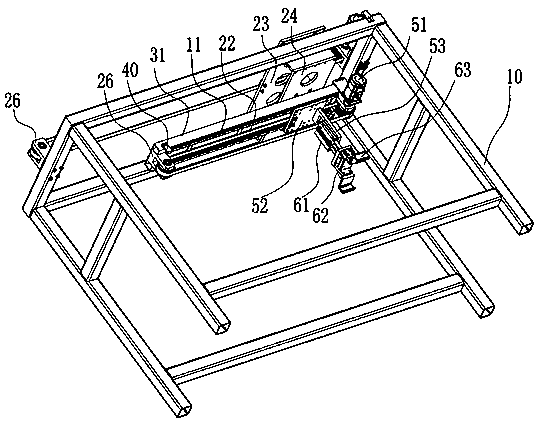

[0024] Such as figure 1 and as figure 2 As shown, the present invention provides a loading and unloading manipulator of an automatic glue dispensing production line. A first driving device 21 is provided on the frame 10. The first driving device 21 is a motor and corresponds to the first driving device 21 on the frame 10. A fixed seat 26 is provided at the position, and a transmission member 22 is connected to the fixed seat 26 and the first driving device 21. In this embodiment, the transmission member 22 is a transmission belt.

[0025] Such as figure 1 As shown, an X-axis motion platform is provided on the frame 10, and the X-axis motion platform is provided with a first connecting plate 23 and a second connecting plate 24, and the first connecting plate 23 and the second connecting plate 24 are stacked. The plate 23 and the second connecting plate 24 are connected by a fixing plate 25 .

[0026] Such as figure 1 As shown, the two sides that the first connection plate ...

Embodiment 2

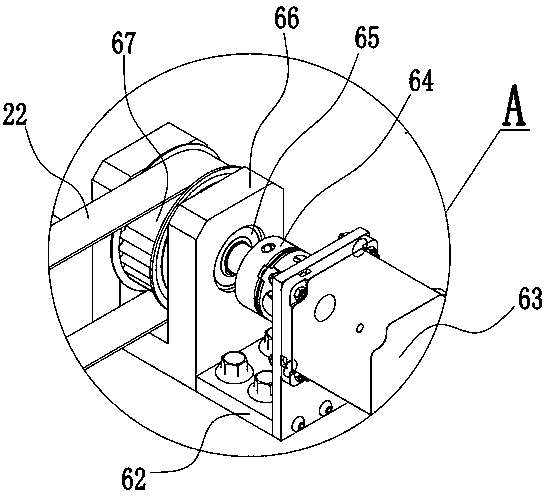

[0036] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, the first driving device 21 is connected to the frame 10 through the installation base plate 62, the first driving device 21 is connected with a coupling 64, and the coupling 64 It is connected with the bearing 65 fixed by the bearing baffle 66 , and the coupling 64 is connected with a synchronous wheel 67 , and the synchronous wheel 67 is connected with the transmission member 22 .

[0037] Similarly, the second drive device 51 is connected to the support beam 31 through the installation base plate 62, the second drive device 21 is connected with a shaft coupling 64, and the shaft coupling 64 is connected with the bearing 65 fixed by the bearing baffle plate 66, while the shaft coupling 64 is connected with synchronous wheel 67, and synchronous wheel 67 is connected with transmission member 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com