Portable device for manufacturing reversed U-shaped steel structure

A portable and section steel technology, which is applied in the field of agricultural equipment, can solve the problems of inconsistent frame specifications, inconvenient transportation and storage, and different site conditions, and achieve the effect of good construction effect and convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

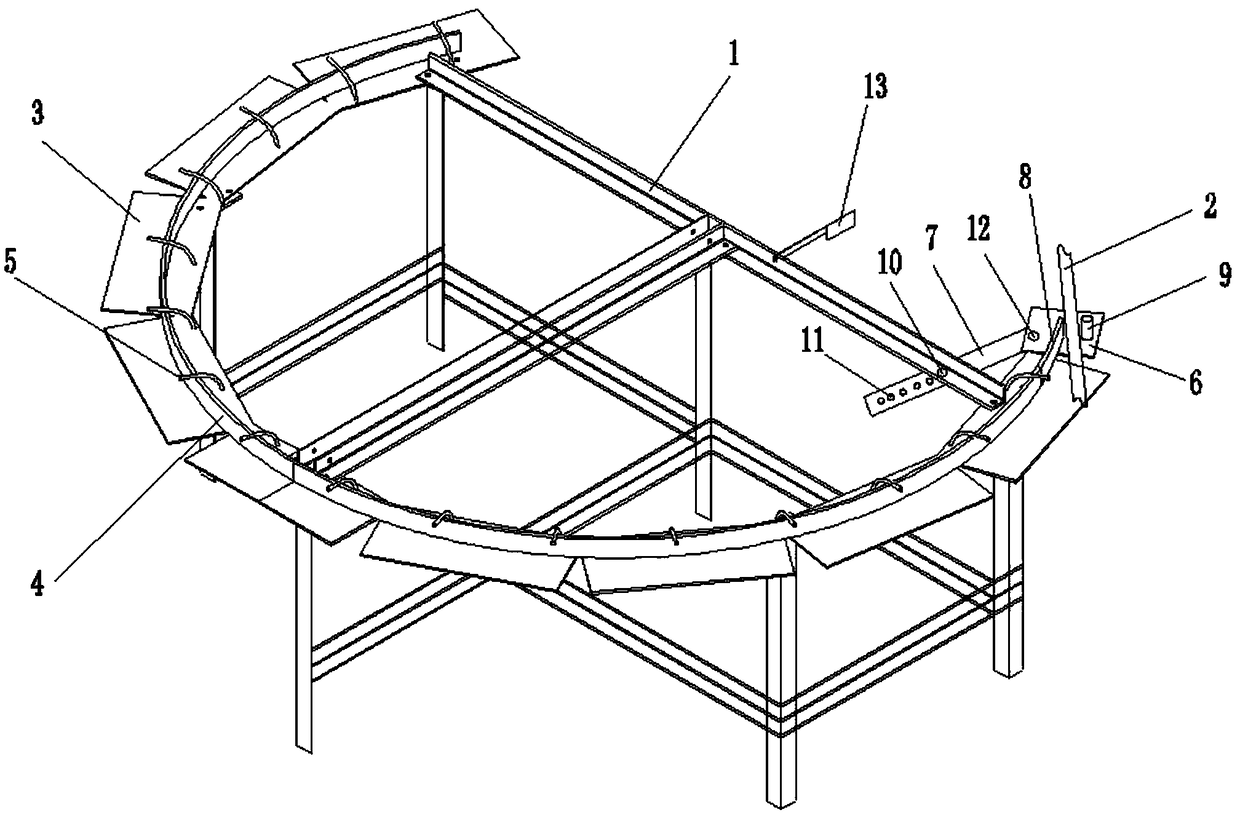

[0024] Such as figure 1 with 2 As shown, a portable device for manufacturing a U-shaped steel structure scaffold includes a frame 1, a forming mechanism and a fixed head. The forming mechanism is semicircular and is fixed on the frame 1. The fixed head is installed on the frame 1 at a position corresponding to the end of the forming mechanism for clamping the middle of the straight steel pipe 2 to bend the straight steel pipe 2 around the forming mechanism, and then the straight steel pipe 2 It is formed into a U-shaped steel structure with straight tubes on both sides and a circular arc tube in the middle (such as figure 2 Shown).

[0025] The forming mechanism includes a support plate 3, a baffle 4 and a bead 5. The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com