Die cutting method for keeping finished product edge of packaging paper box being flush with paper gripper edge

An edge and paper technology, which is applied in the field of die-cutting where the edge of the finished packaging carton is flush with the edge of the paper mouth, can solve the problems of reducing waste paper edges, reducing connection points, and paper edge waste, saving paper costs, The effect of reducing connection points and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and embodiments.

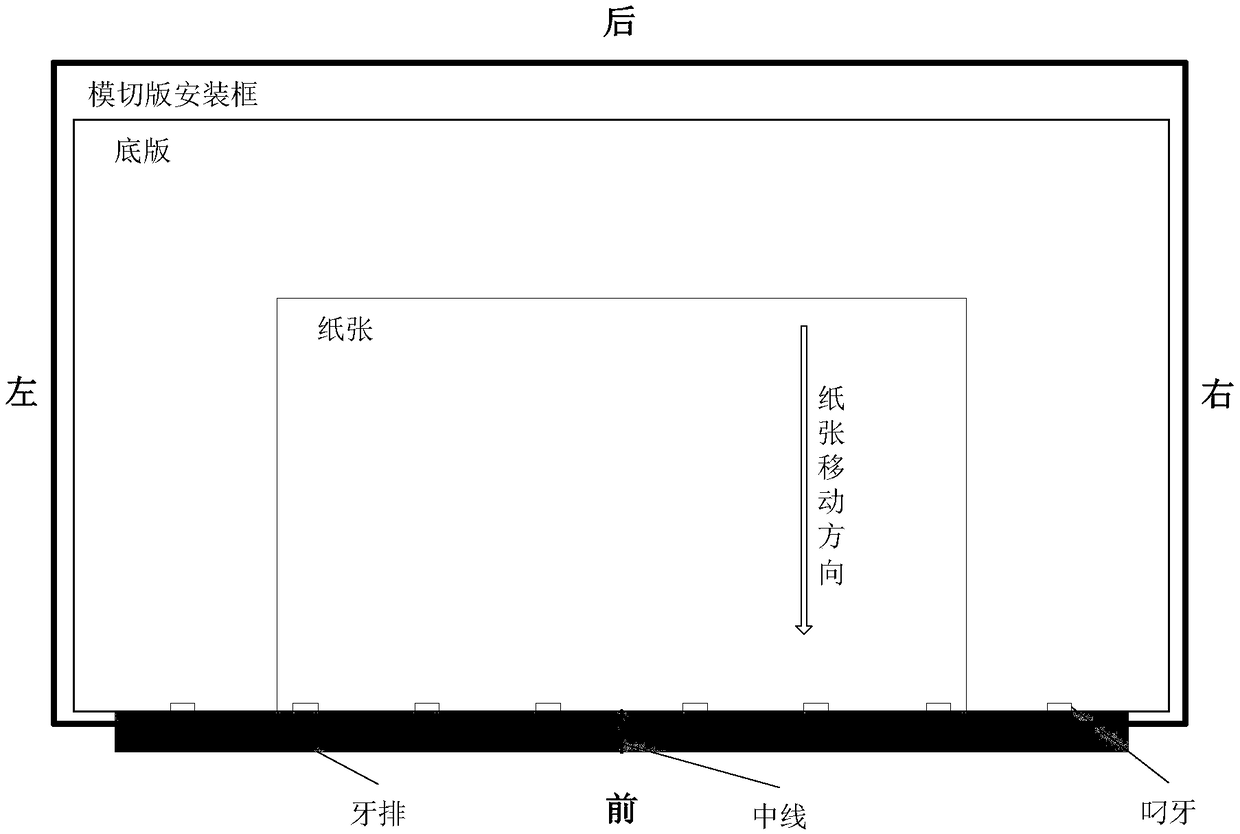

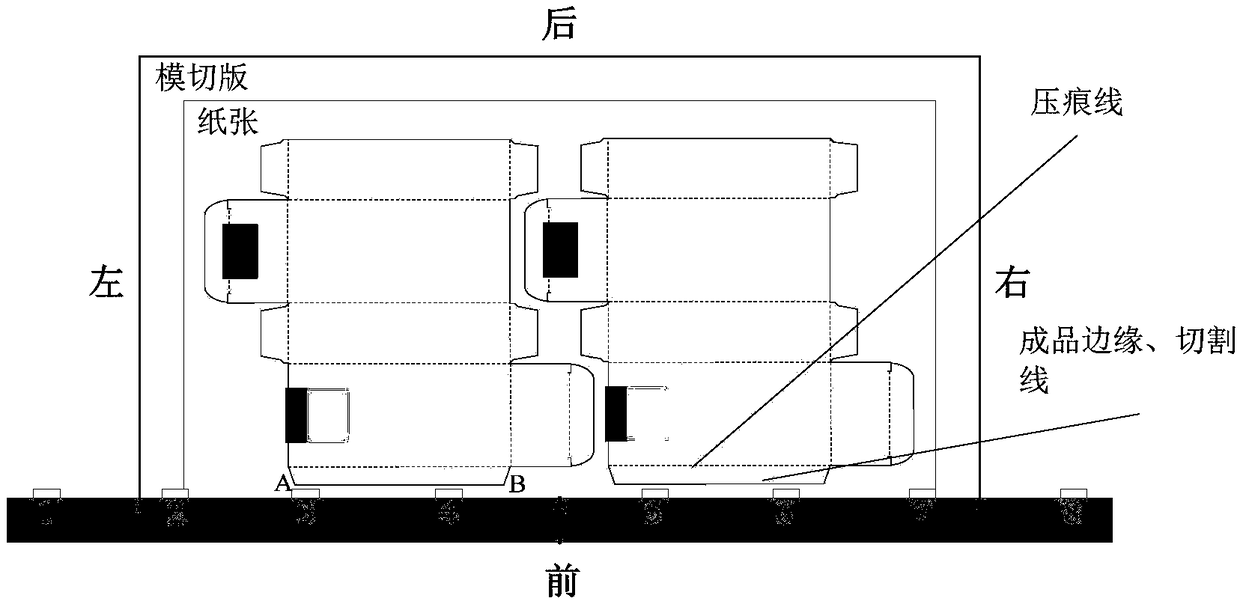

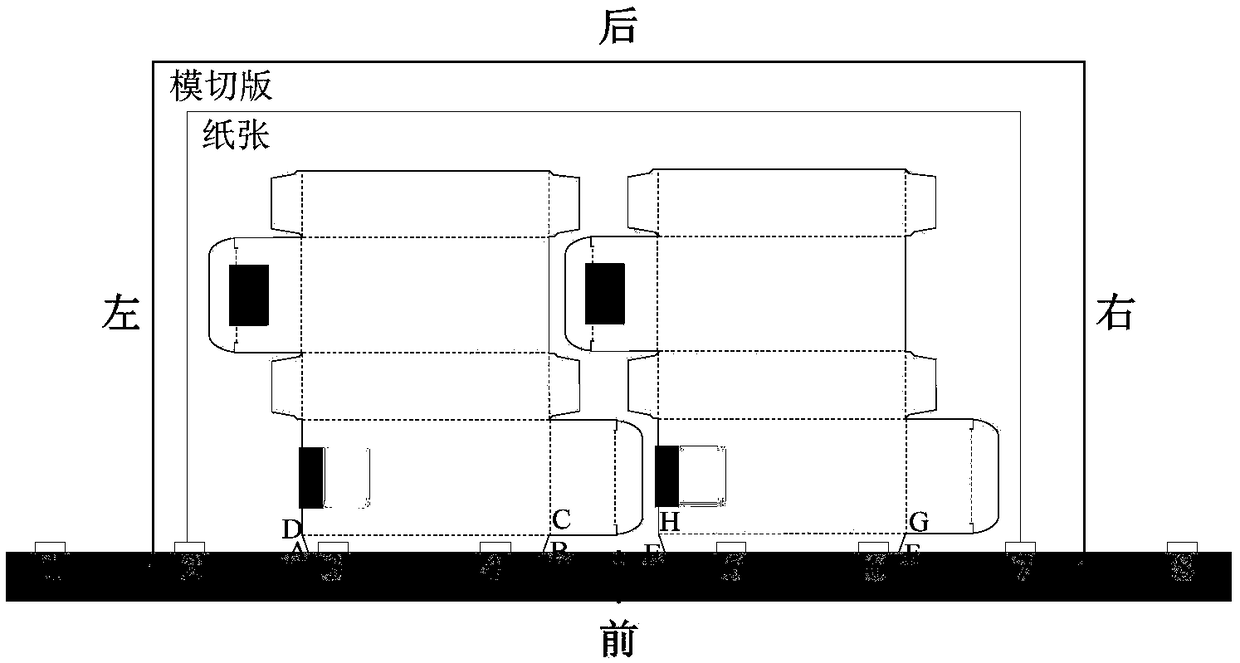

[0027] In the packaging and printing industry, the die-cutting and forming processing of sheet paper mainly adopts the horizontal flat-bed die-cutting machine with automatic paper feeding for die-cutting and creasing processing. On a typical horizontal flat die-cutting machine, the relative positions of the die-cutting master, die-cutting plate mounting frame, and the biter row are fixed. The position of the paper relative to the die-cutting master during die-cutting can pass the front gauge A small amount of movement in the front and rear direction is performed, and a large amount of movement in the left and right direction is performed by the side guide. When the front rule is at the reference position, the relative positions between the die-cut master, die-cut plate mounting frame, the biter row and the paper are as follows: figure 1 As shown, the gripping e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com