A matching structure of an automobile seat belt interface and a carpet

A technology for matching structures and seat belts, applied in the field of automotive interiors, can solve problems such as different shapes, assembly errors, and increase the difficulty of carpets, so as to simplify the difficulty, improve compatibility, and solve the problem of material placement and assembly error prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

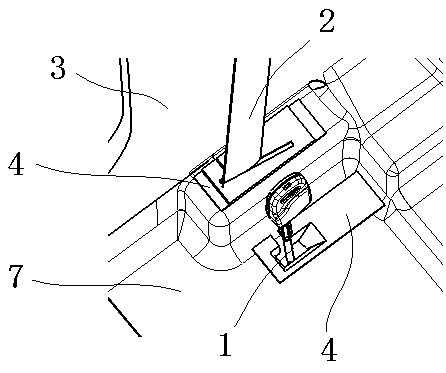

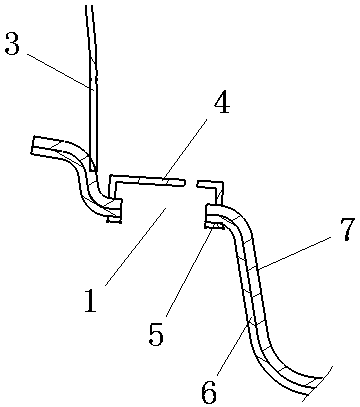

[0018] This embodiment proposes a matching structure between the car seat belt interface and the carpet, so that the carpet can be matched with high and low seat belts, thereby reducing the difficulty of carpet material management and identification before assembly.

[0019] Such as figure 1 As shown, the matching structure of the car seat belt interface and the carpet in this embodiment includes a high-profile seat belt interface 1 and a low-profile seat belt interface 2 arranged at intervals, wherein the low-profile seat belt interface is located at the bottom of the automobile B-pillar 3, so The avoidance part of the high configuration seat belt interface is located at the side of the low configuration seat belt interface 2, and the lower configuration seat belt interface 2 is closer to the central axis of the vehicle. The carpet 7 is provided with a high-configuration seat belt interface avoidance part and a low-configuration seat belt interface avoidance part respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com