Full-automatic filling production line of cosmetic spray

A fully automatic, aerosol technology, applied in packaging, packaging machines, packaging protection and other directions, can solve the problems of low production efficiency, inverted bottle capping, bottle stuck, etc., to achieve high production efficiency and solve the effect of bottle stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings.

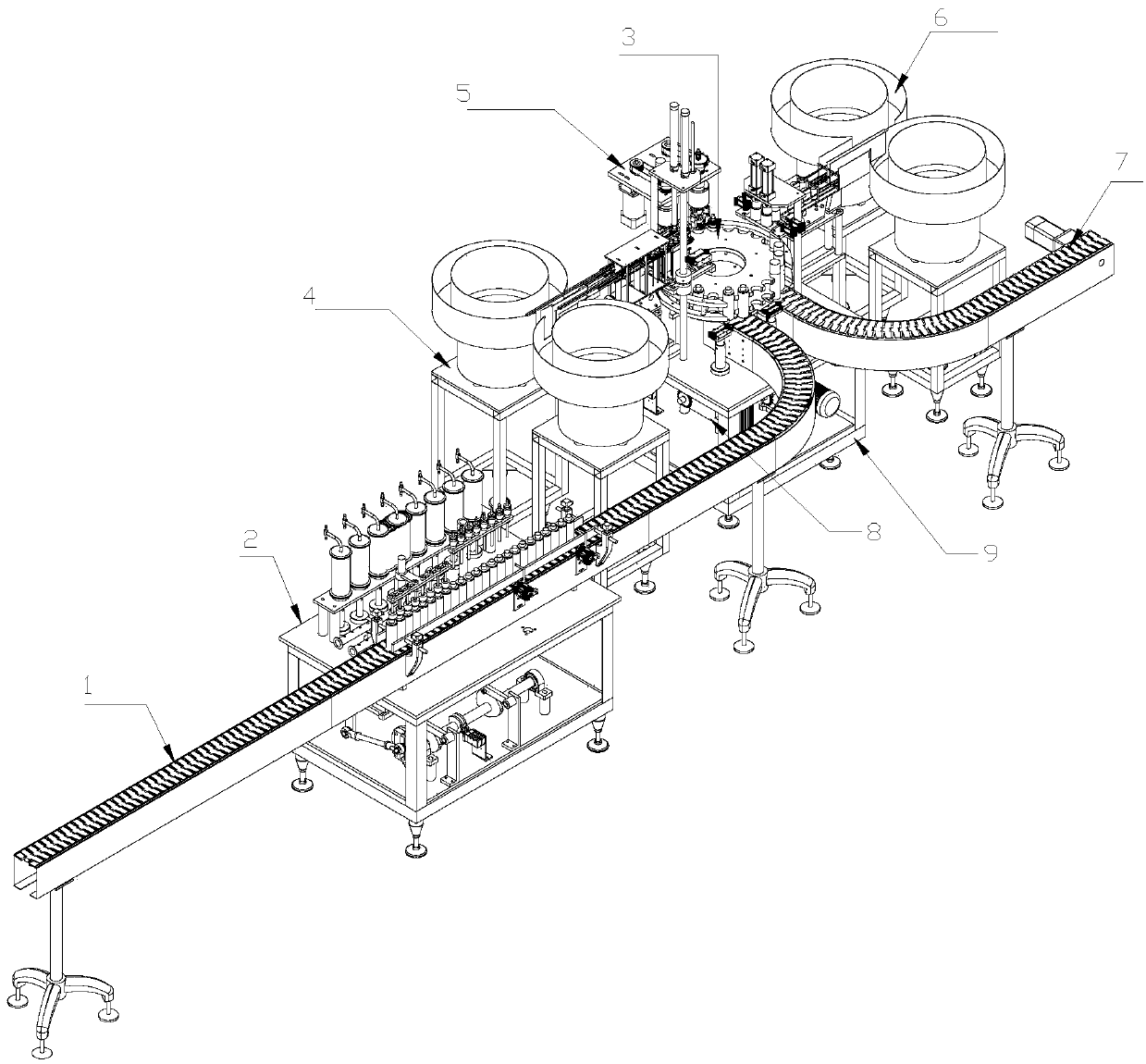

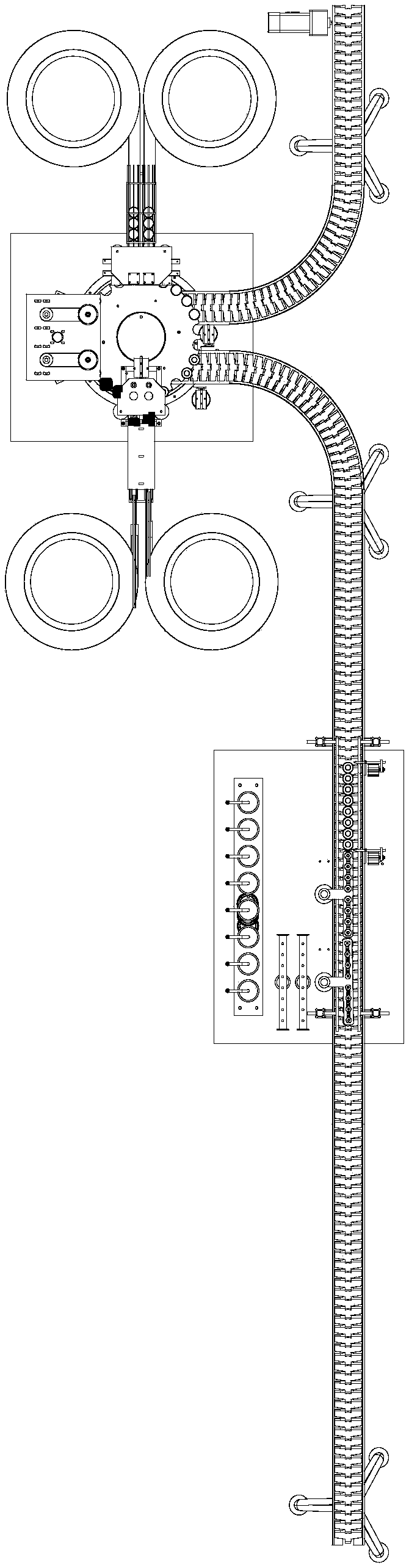

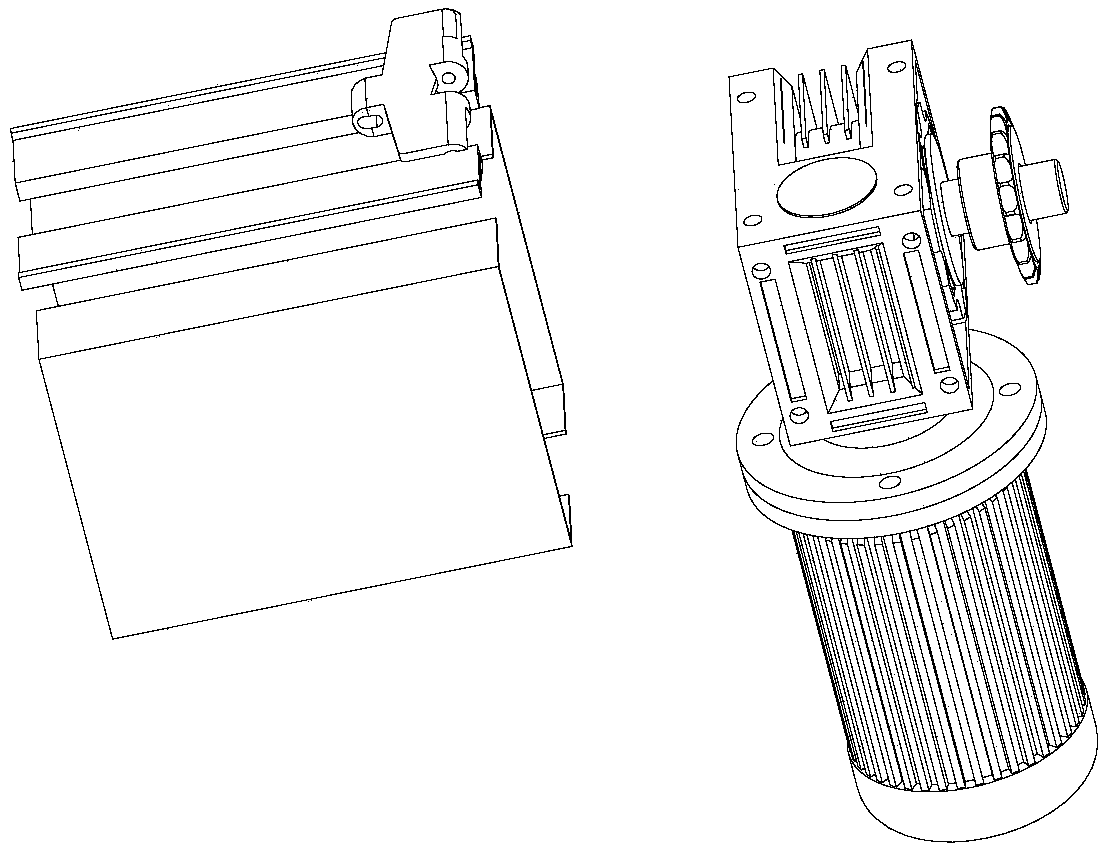

[0049] Such as figure 1 , figure 2 A full-automatic filling production line for cosmetic sprays is shown. The filling production line includes a bottle feeding device 1, a liquid filling device 2, a turntable device 3, a pump body mounting device 4, a pump body tightening device 5, and a cap Install the pressing device 6, the bottle conveying device 7, the splitting machine 8, the table frame 9 and the motor assembly. Such as Figure 4 , Figure 5 As shown, the liquid filling device 2 includes a first reducer 21, a first motor 22, a main drive shaft 28, a first table 23, a liquid supply device 24, a liquid filling device 25, a blowing device 26 and a bottle stopper. Institutional assembly 27. The liquid filling device 2 is arranged on the first table 23 as a whole, and the bottle feeding conveying device 1 is arranged above the first table 23 through pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com