Balancing device applied to pavement embossing machine

A technology of balancing device and embossing machine, which is applied in the directions of roads, roads, and road repairs, can solve the problems of uneven stress on embossing rollers, different depths of road textures, and easy adhesion of embossing sticks to soil layers, so as to avoid The effect of uneven force, reducing viscosity and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

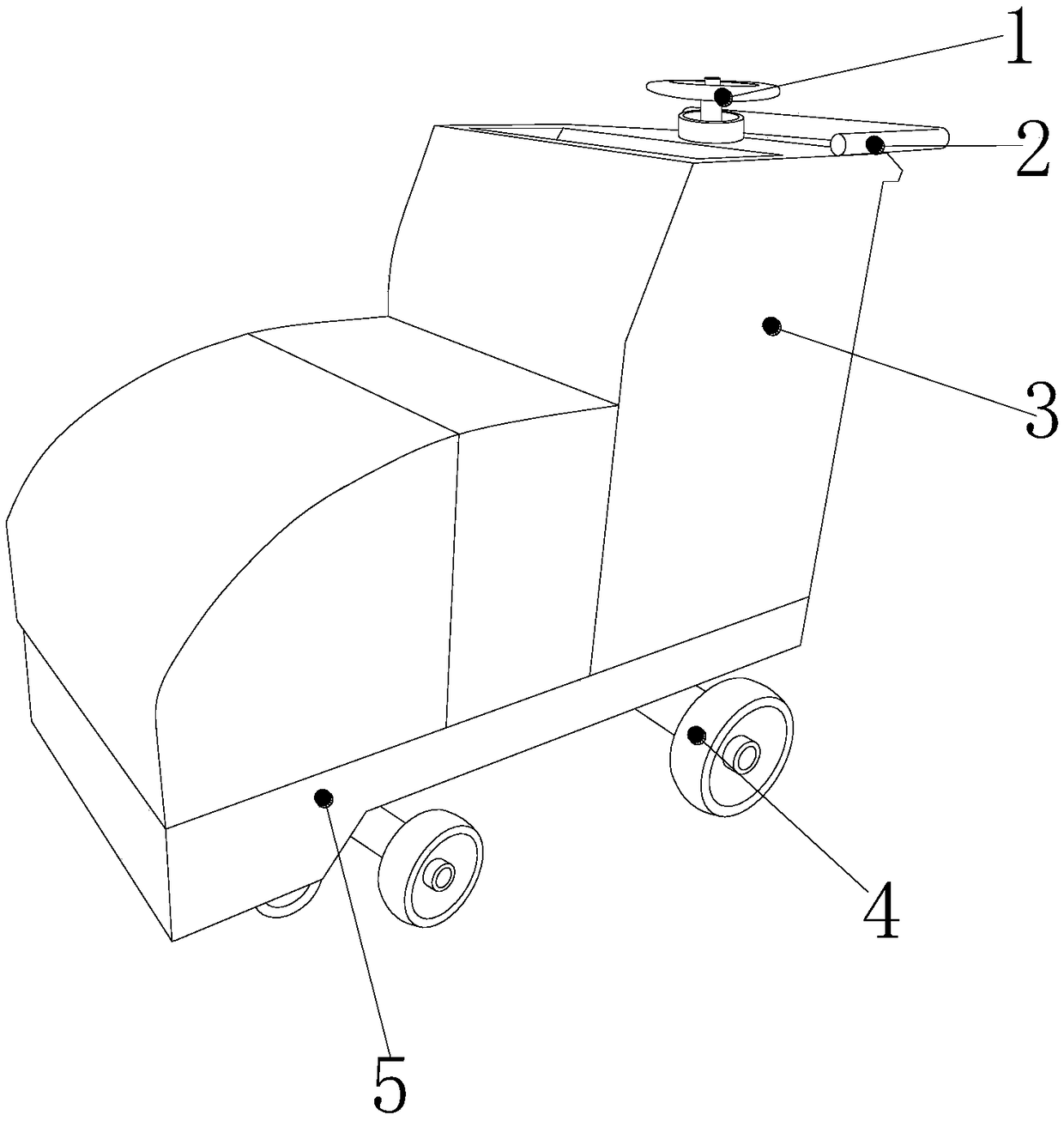

[0022] See Figure 1-Figure 4 , The present invention provides a balancing device applied to a road embossing machine. Its structure includes a hand wheel 1, a handle 2, a housing 3, a caster wheel 4, and a balancing mechanism 5. The hand wheel 1 is mechanically connected to the housing 3, and the handle 2 is connected to the hand wheel 1 through the housing 3, the balance mechanism 5 is installed inside the housing 3, the casters 4 are provided with four and are respectively installed on the four corners of the bottom of the housing 3, the casters 4 and The shell 3 is connected.

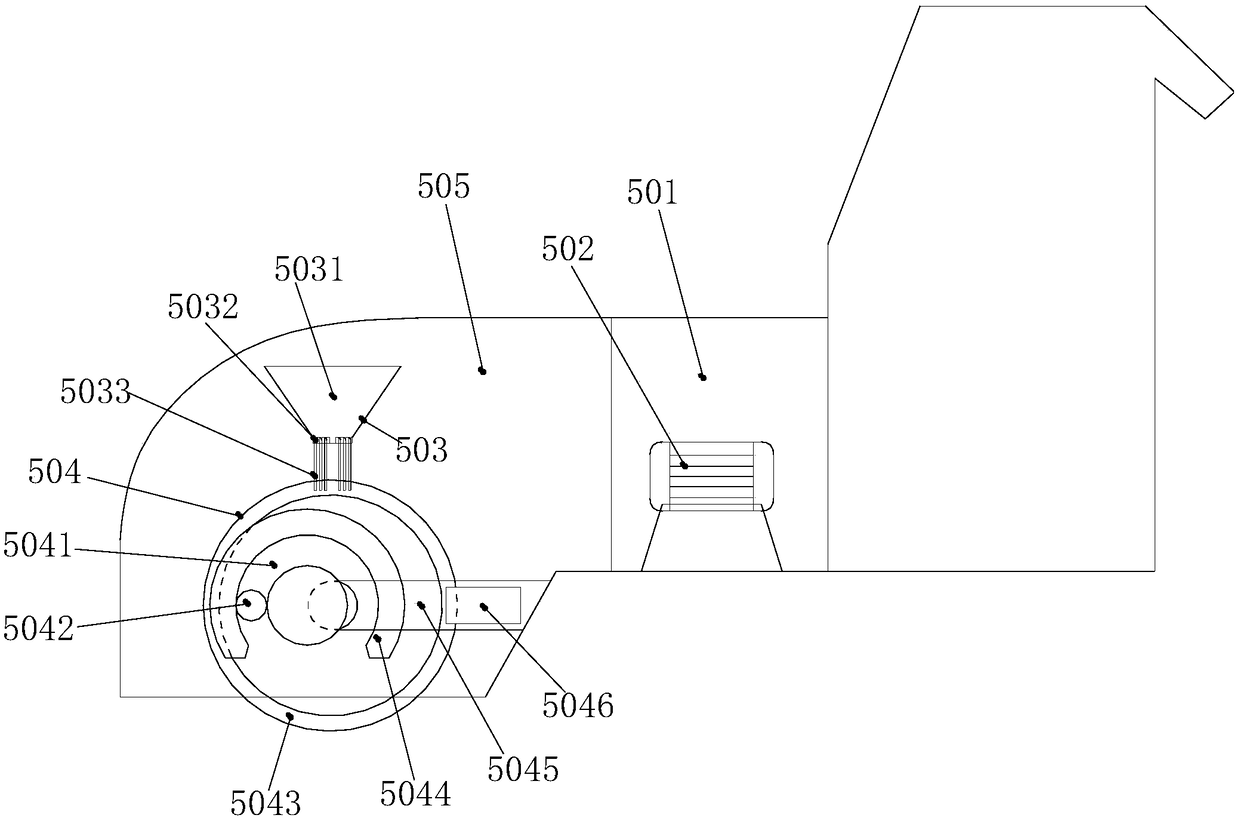

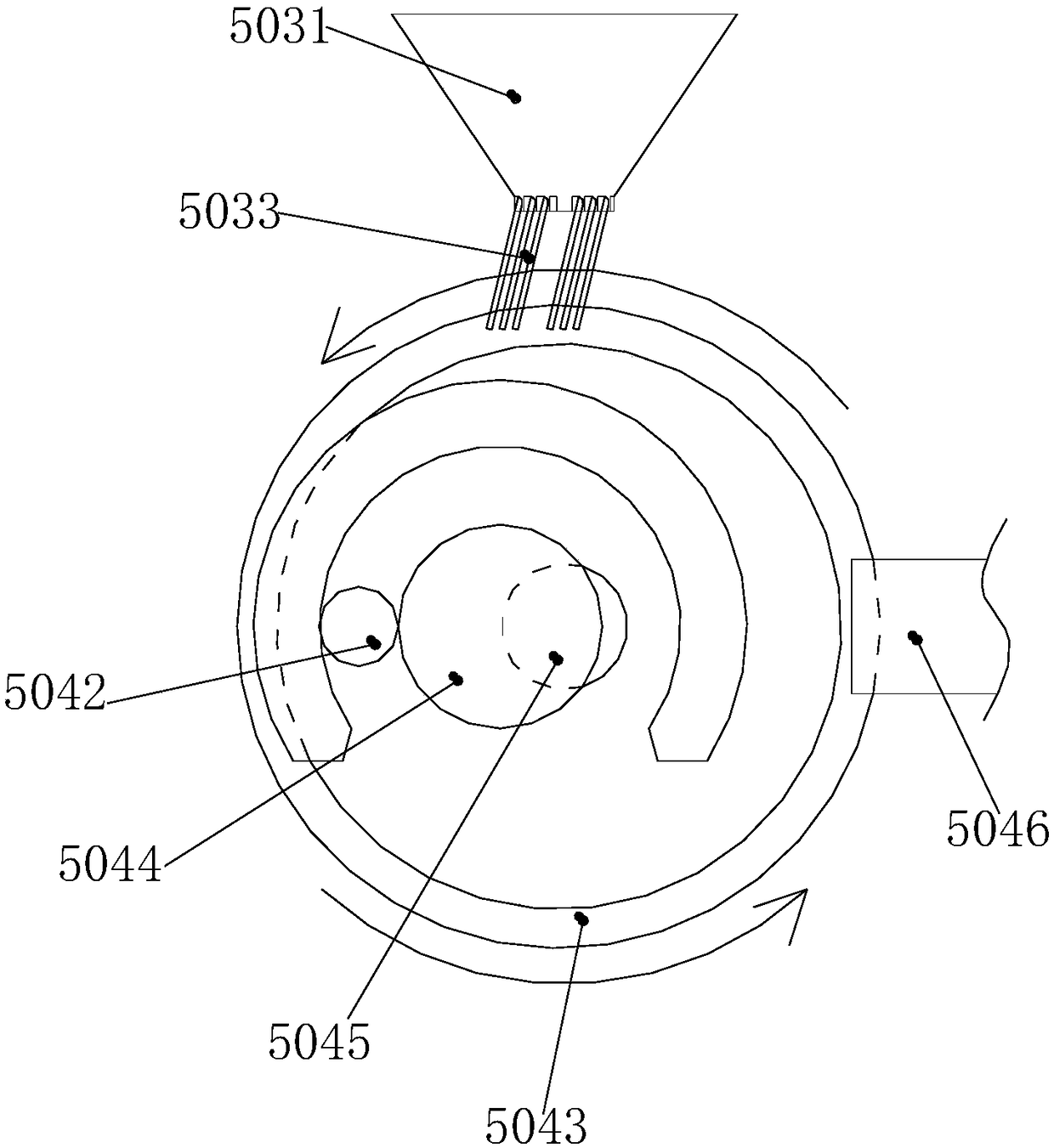

[0023] The balance mechanism 5 is composed of a first cavity 501, a motor 502, a humidifying device 503, a calibration balance mechanism 504, and a second cavity 505. The first cavity 501 is provided with a motor 502, and the first cavity 501 Connected to the second cavity 505, the second cavity 505 is provided with a humidification device 503 and a calibration balance mechanism 504, and the humidific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com