Gas fire source device for building member simulation fire experiment and use method

A technology for building components and experiments, applied in the field of building structure fire protection, can solve problems such as infiltration, lack of consistent gas flow design, difficult building components temperature rise behavior and fire resistance research, etc., to achieve the effect of uniform airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

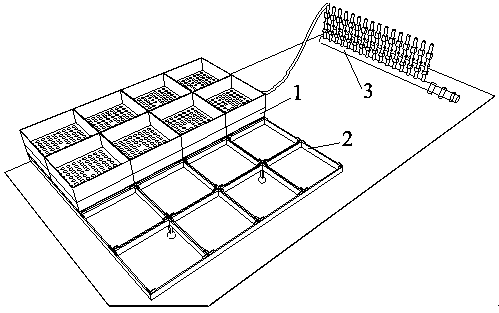

[0081] like Figure 1 to Figure 15 As shown, a fire source device for building component fire simulation experiments includes a burner 1 , a moving bracket 2 , and a gas distribution device 3 .

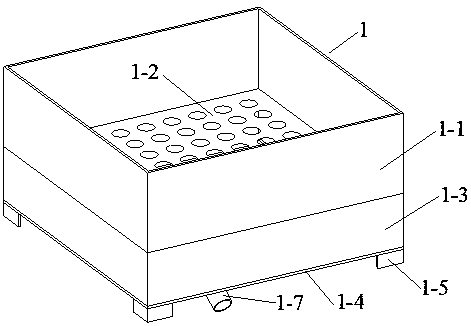

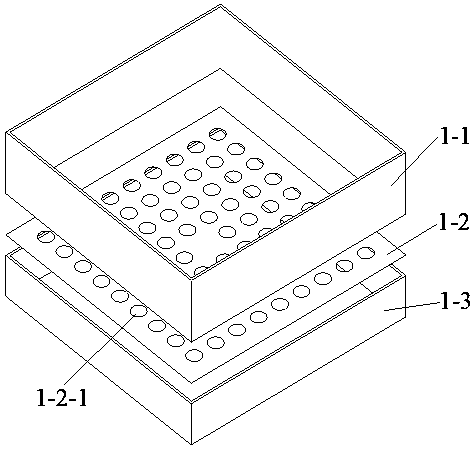

[0082] The burner 1 includes a square frame Ⅰ1-1, a sand screen 1-2, a square frame Ⅱ1-3, a chassis 1-4, an L-shaped foot Ⅰ1-5, a short support rod 1-6, and a gas delivery bend Tubes 1-7, X-shaped air-distribution coils 1-8 or back-shaped air-distribution coils 1-9 or Wang-shaped air-distribution coils 1-10.

[0083] Both the sand separation screen 1-2 and the chassis 1-4 are in the shape of a square plate, and several air outlet holes I1-2-1 are arranged in a matrix on the plate surface of the sand separation screen 1-2.

[0084] The center of the plate surface of the chassis 1-4 is provided with an elbow hole 1-4-1, and a circle of edge protrusions 1-4-2 is arranged around the plate surface of the chassis 1-4, and the edge protrusions 1-4-2 The side length is smaller than the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com