Testing device and testing method for lift force of valve disc of safety valve

A testing device and safety valve technology, which can be used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as difficulty in testing valve disc lift, and achieve real-time display, high acquisition accuracy, and increased sealing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

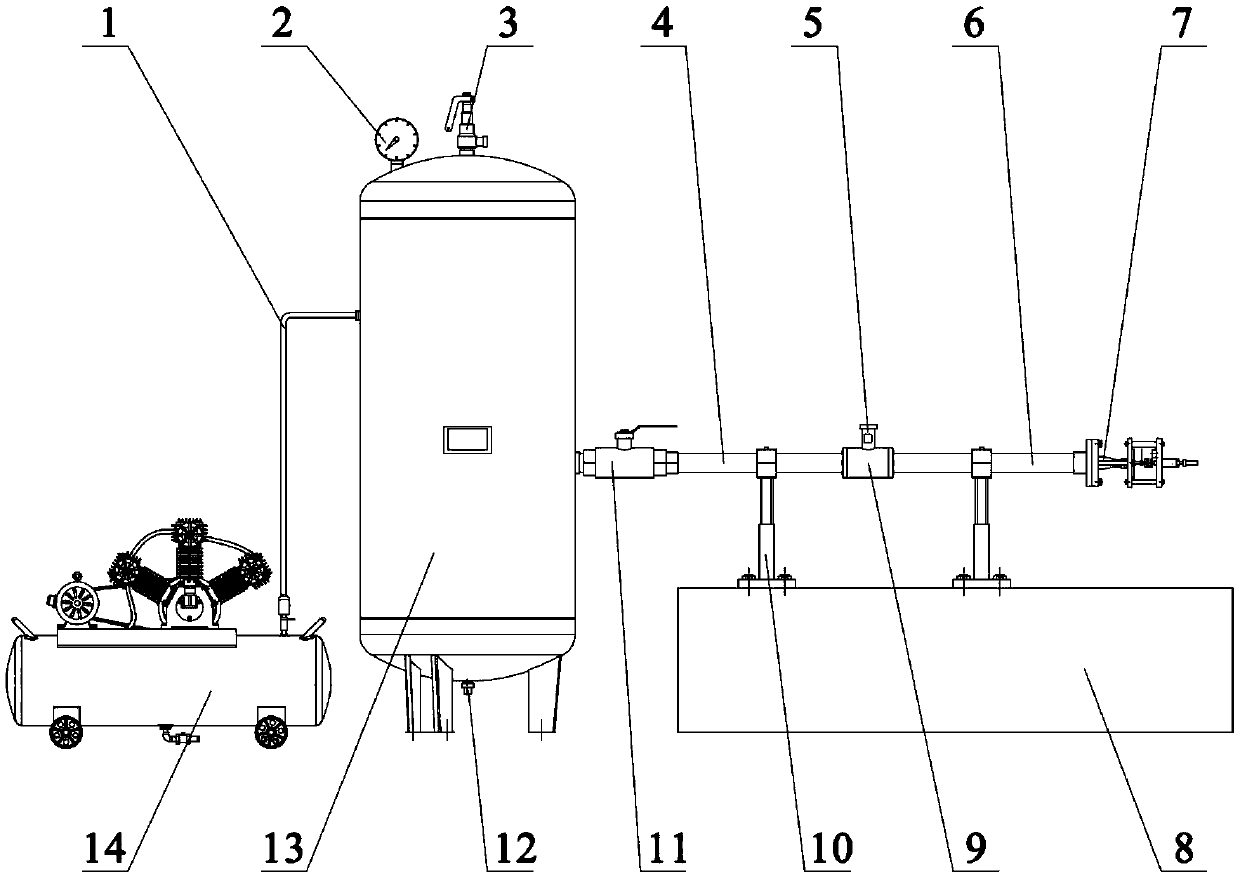

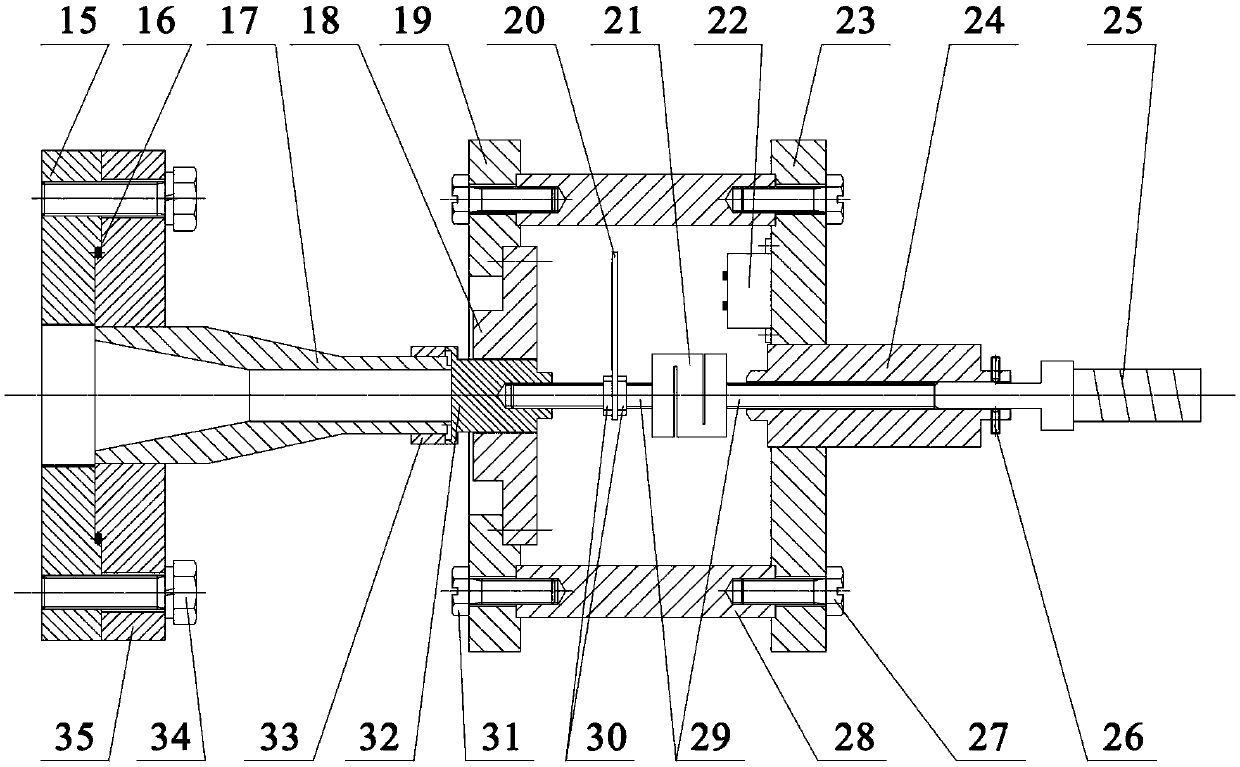

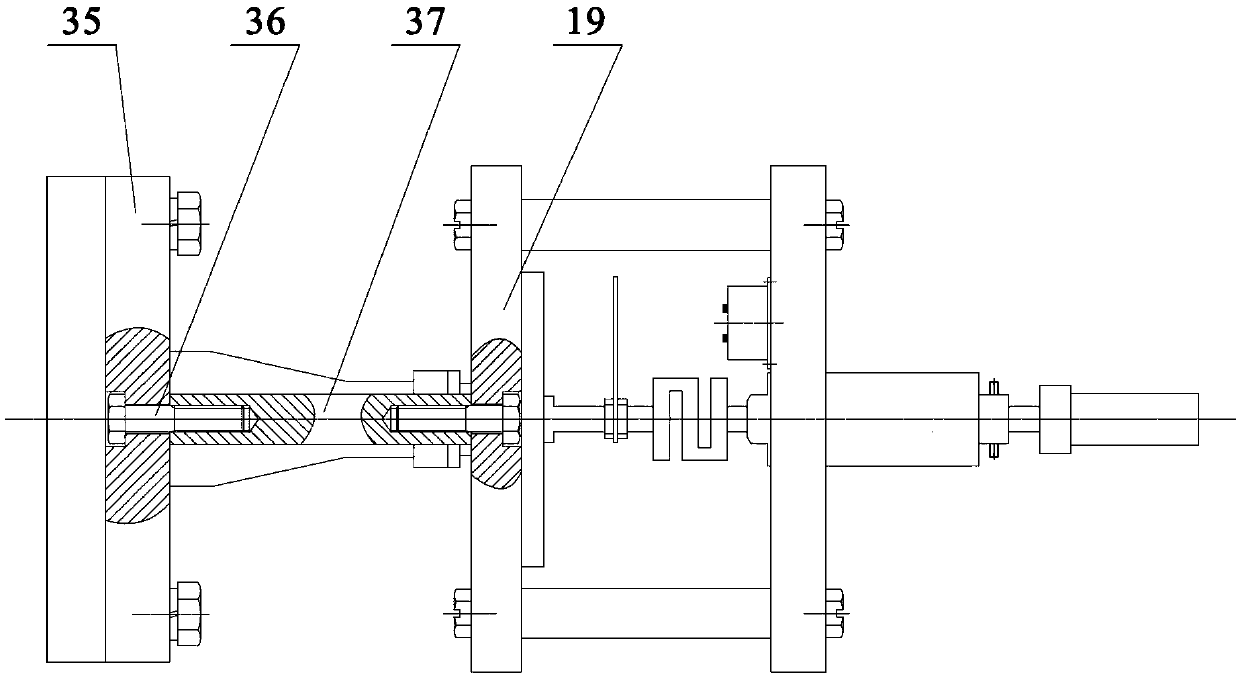

[0035] Below in conjunction with accompanying drawing, the present invention is described in more detail:

[0036] The overall structure of the safety valve disc lift test device is shown in the figure. figure 1 As shown, the air compressor 14 and the air storage tank 13 are connected by the connecting pipe 1, the pressure gauge 2, the pressure relief valve 3 and the drain valve 12 are installed on the air storage tank 13, and the air storage tank 13 and the left end of the ball valve 11 are connected by screws , and wrapped with raw tape, the right end of the ball valve 11 is connected with the pipeline A4 through threads, and wrapped with raw tape, the pipeline A4 is supported on the experimental bench 8 by the pipeline bracket 10, and the pipeline bracket 10 is fixed on the experimental bench 8 through T-bolts, The right end of the pipeline A4 is connected with the air pressure sensor connector 9, the air pressure sensor 5 and the air pressure sensor connector 9 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com