Three-directional force measurement device and measurement method for large thrust rocket engine

A technology of rocket engine and measuring device, which is applied in the direction of measuring device, engine test, force/torque/work measuring instrument, etc., can solve the problems of reduced measurement accuracy, inability to effectively ensure measurement accuracy, etc., to ensure measurement accuracy , The effect of solving accurate measurement interference and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

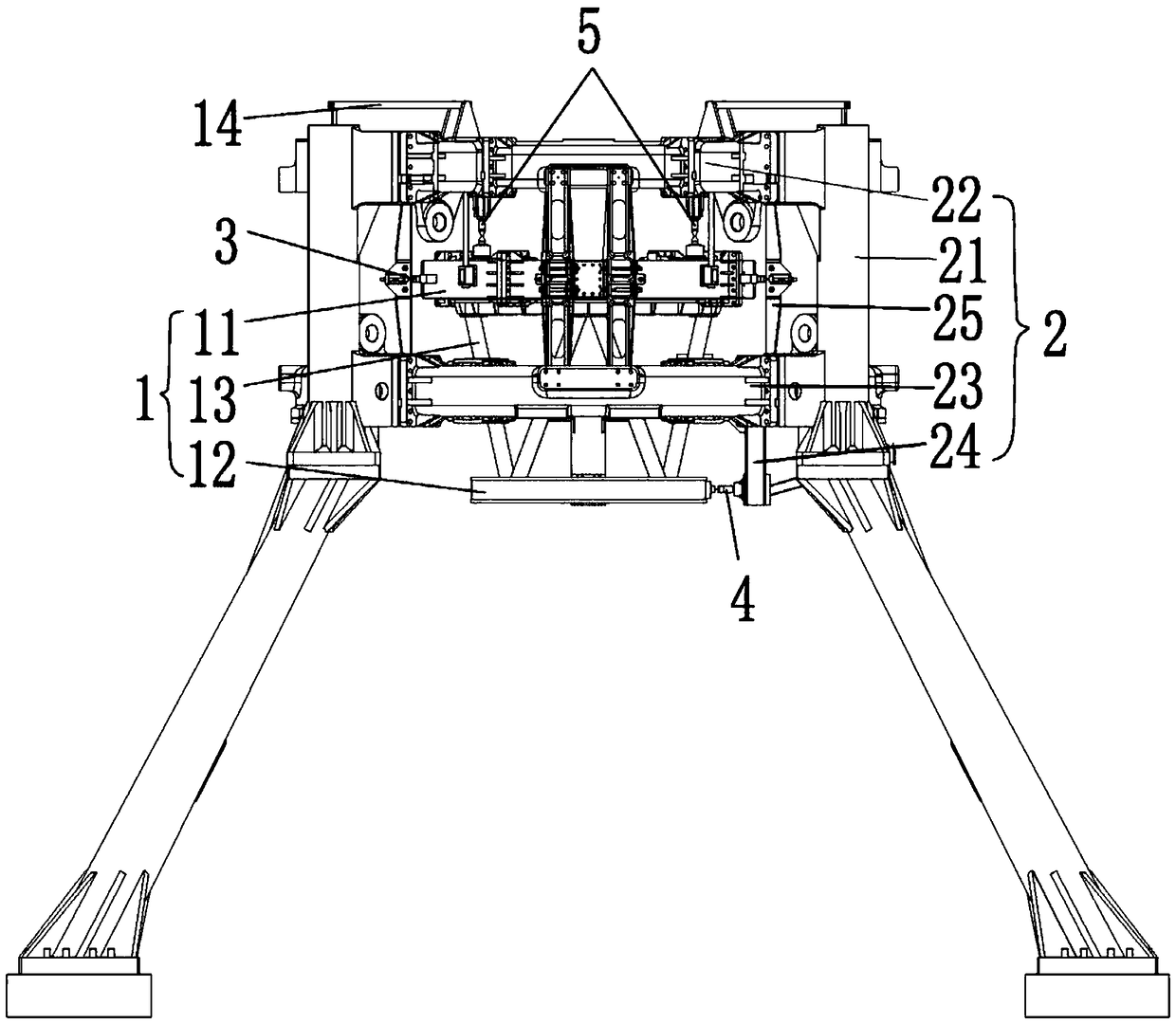

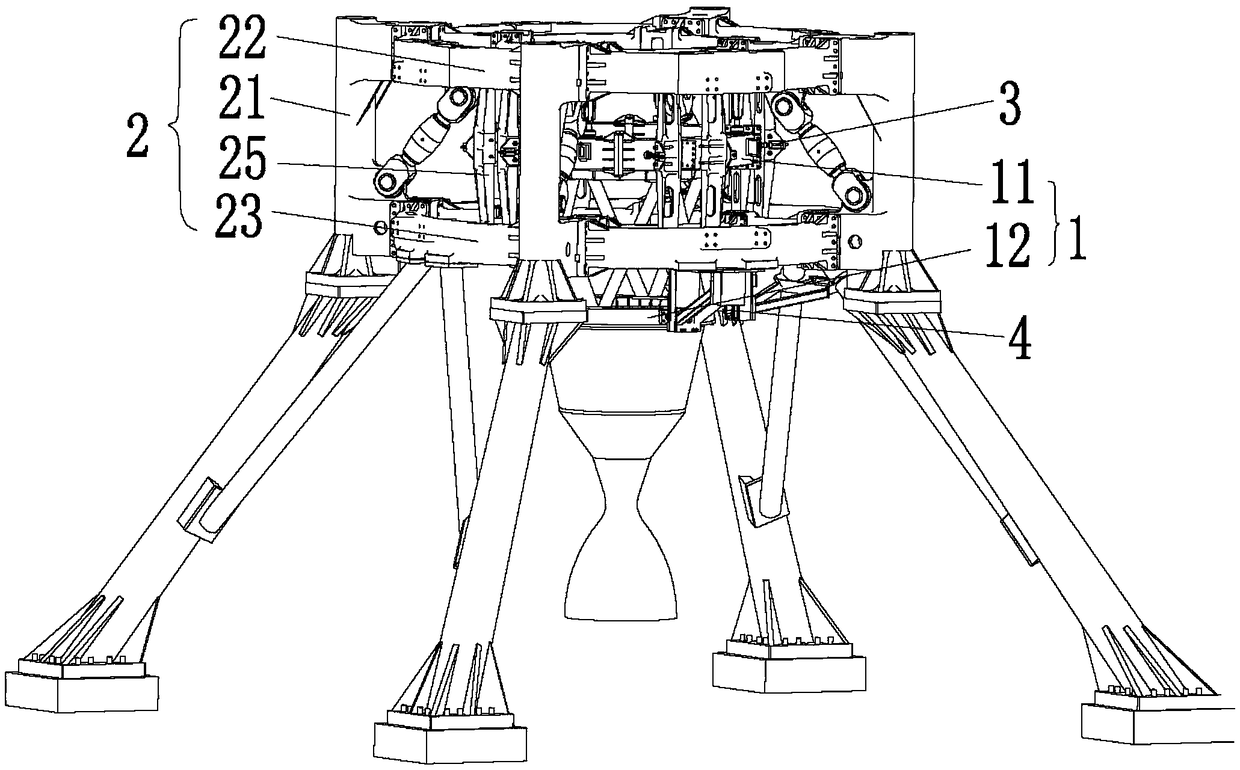

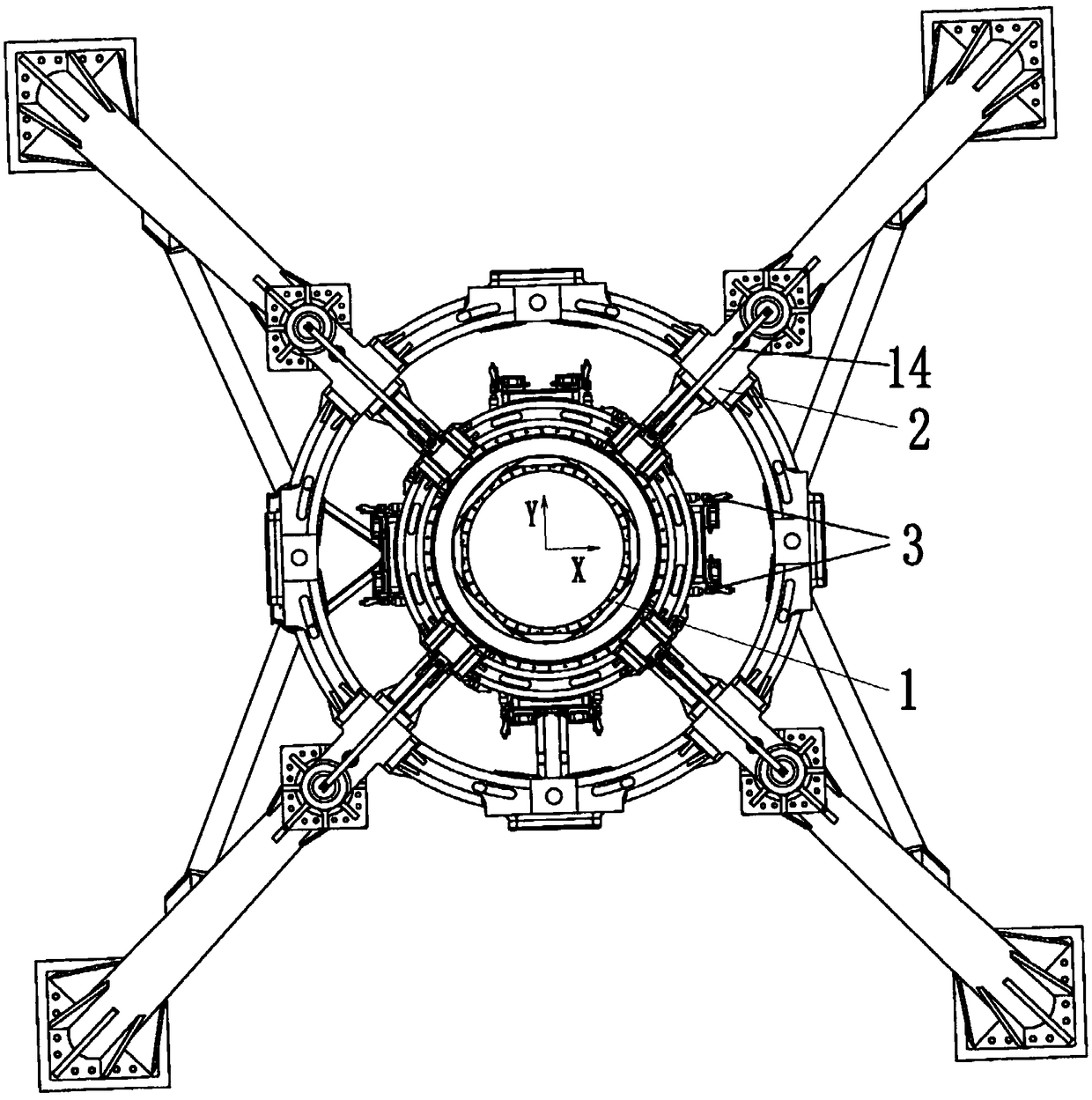

[0051] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0052] In the present invention, a three-way force measuring device is additionally installed on the test frame of the 1200kN rocket engine to measure the lateral thrust of the 1200kN high-thrust rocket engine. Utilize the measuring device provided by the present invention, apply the lateral thrust of different directions and different sizes by means of the calibration force source, obtain the measured value of the sensor in each three-direction force measuring device, and establish the relationship between the measured value of each force sensor and the three-direction force of the engine The calculation model (correction formula) between them is used, and the method of in-situ calibration of engine thrust is used to fit and obtain the size of each correction coefficient in the calculation model. In the actual lateral thrust me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com