Automatic testing device for complete machine function

An automated testing and functional technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of high production cost, manual misjudgment, long cycle, etc., and achieve short development cycle and convenient storage. The effect of uploading and reducing the R&D cycle

Active Publication Date: 2018-12-25

FUJIAN NEWLAND PAYMENT TECH

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the field of electronic product production, POS machine testing is mostly done manually, and fixtures need to be customized, resulting in low efficiency, manual misjudgment, high production cost, long cycle and other unfavorable factors. In order to realize automated testing, it is necessary Requires a test plan that is highly versatile and free from manual testing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0046] When the cash register test is performed on the POS machine, the PC program continuously sends query instructions to the motion control board to verify whether the POS machine is placed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

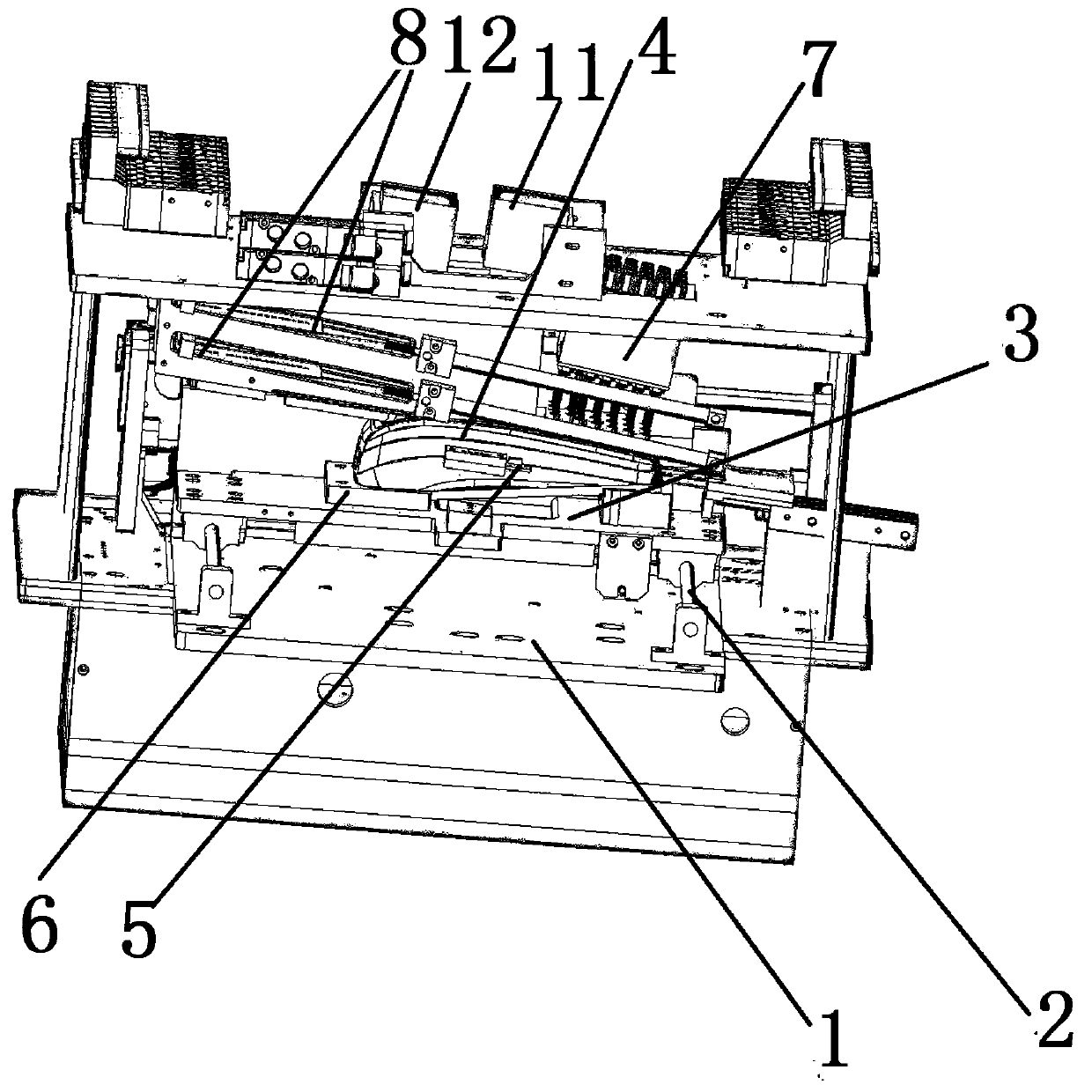

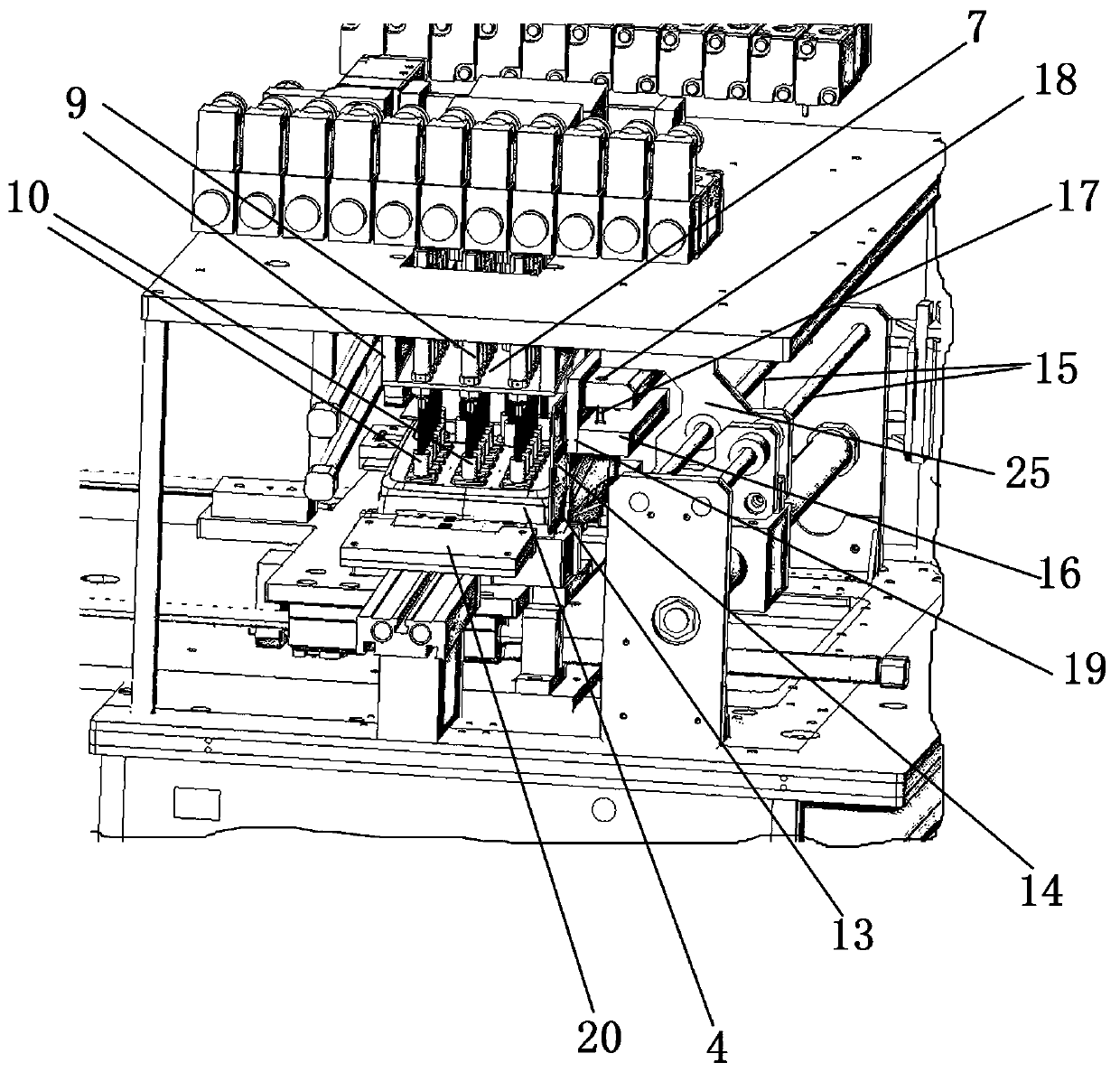

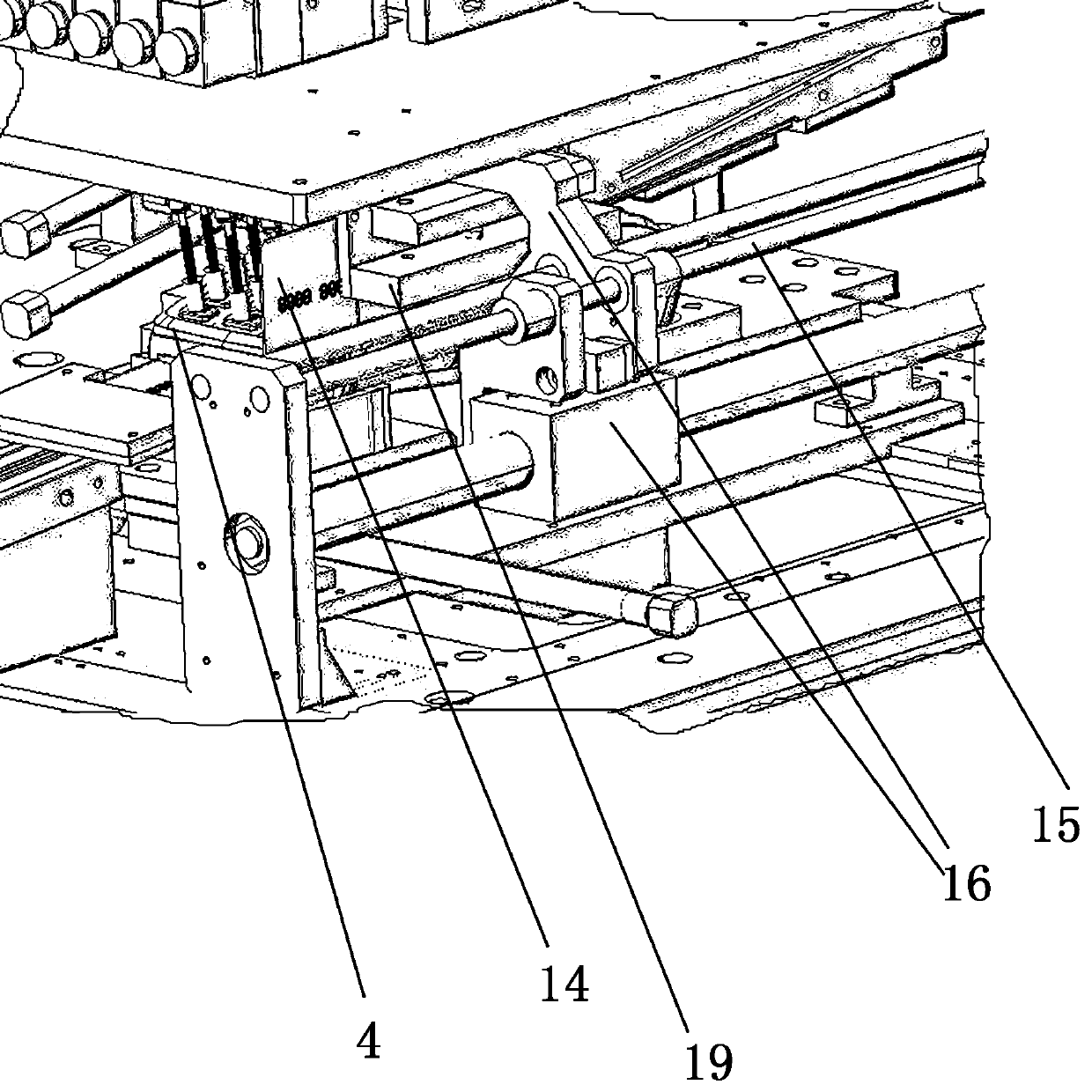

The invention provides an automatic testing device for a complete machine function, comprising a control module, an image recognition module, a communication module, a key testing station, a screen testing station, a printing test station, a card swiping test station, a tray for fixing a POS machine to be tested, an machine placement area and an machine testing area. A plurality of telescopic keyboard point pressing rods are arranged at the key testing station; a first camera used for shooting a POS machine screen is arranged at the screen testing station; a second camera used for shooting thePOS machine printing bill is arranged at the printing test station; the first camera and the second camera are connected with the image recognition module; the pressing point of keyboard point pressing rods is close to the keyboard of the POS machine after the POS machine is fed into the machine testing area; The first camera faces the POS machine screen; the second camera faces the printout endof the POS machine; the card swiping test station is close to the side edge of the POS machine; The control module is connected with the POS machine through the communication module to obtain the working data of the POS machine. According to the automatic testing device for complete machine function, full-automatic integrated testing can be performed on the POS machine.

Description

technical field [0001] The invention relates to the technical field of testing equipment, in particular to an automatic testing device for complete machine functions. Background technique [0002] At present, in the field of electronic product production, POS machine testing is mostly done manually, and fixtures need to be customized, resulting in low efficiency, manual misjudgment, high production cost, long cycle and other unfavorable factors. In order to realize automated testing, it is necessary A test plan that is highly versatile and free from manual testing is required. Contents of the invention [0003] The invention proposes an automatic test device for the whole machine function, which can carry out fully automatic integrated test on the POS machine. [0004] The present invention adopts the following technical solutions. [0005] An automatic test device for complete machine functions, used for automatic test of POS complete machines, said test device includes...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00G01M13/00G01N21/88G01R31/00

CPCG01M13/00G01M99/005G01N21/88G01R31/00

Inventor 张俊华郑修武江彬

Owner FUJIAN NEWLAND PAYMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com