Global and local batch process fault detection method based on dynamic orthogonality

A fault detection, global technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve generalized orthogonal problems without considering generalized orthogonal problems, loss of useful information, inability to adequately maintain global and local structure of process data, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The method of the present invention will be further described below in conjunction with specific examples.

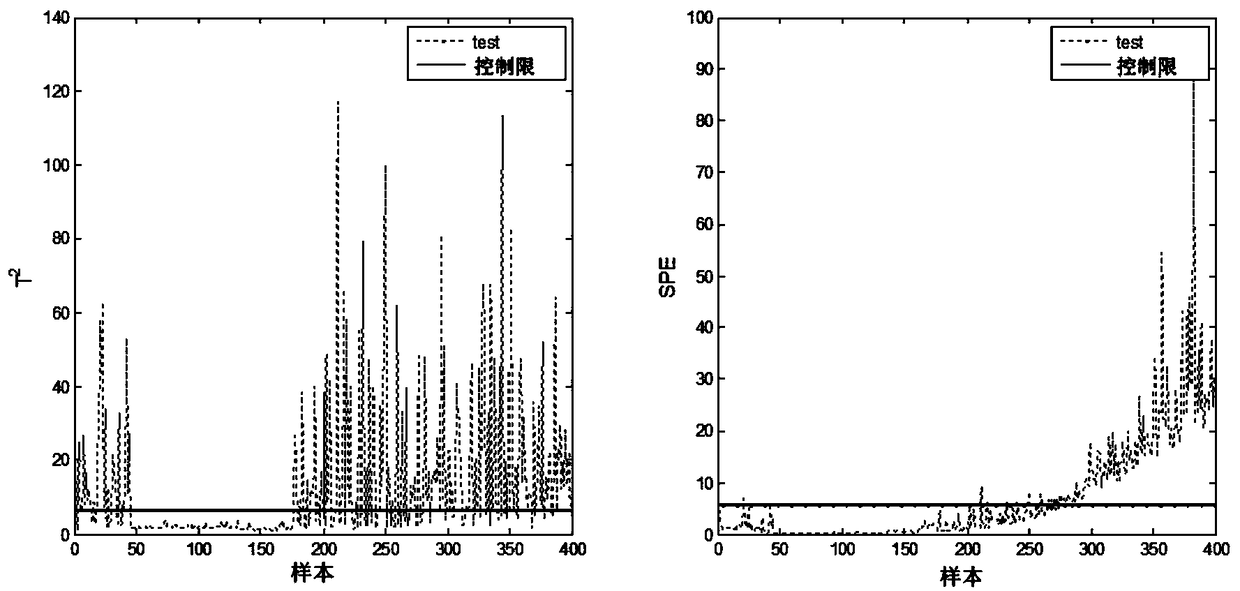

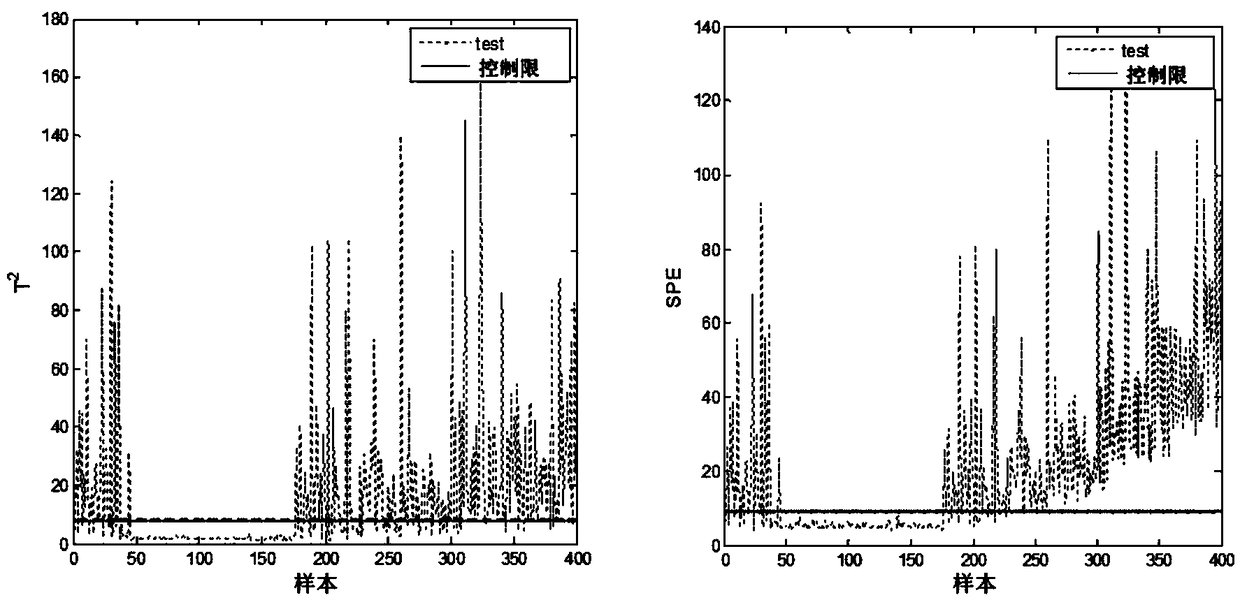

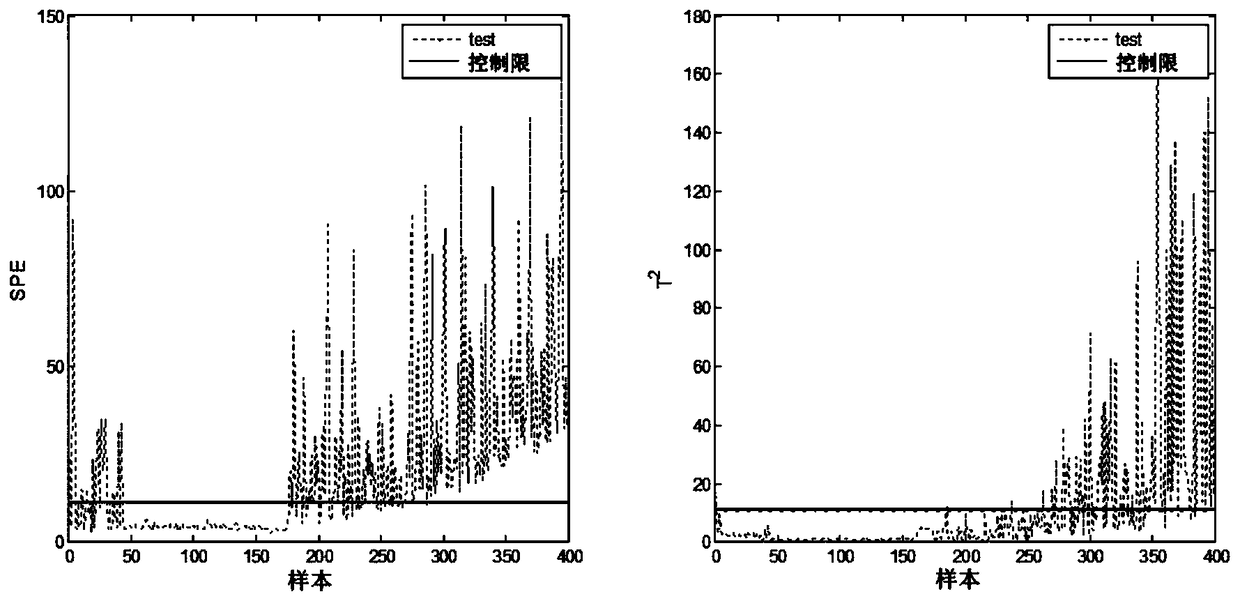

[0075] The penicillin production process is a typical dynamic, nonlinear, time-varying, multi-stage batch process. The present invention generates batch process data through Pensim2.0 standard simulation platform of penicillin fermentation process. Pensim2.0 is developed by Illinois State Institute of Technology in the United States in order to study typical batch processes more conveniently. It can produce different initial conditions and different process data. Under the circumstances, the data of each variable and each moment in the penicillin fermentation process are used for analysis and research. In the penicillin fermentation model, the effects of temperature change, pH value, air flow change, substrate flow acceleration rate, stirring rate, etc. on the bacterial synthesis during the fermentation process are fully considered, and the actual process of peni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com