An automatic laminating device for transformer iron core

A transformer core and laminated device technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of large labor costs, heavy workload, and low production efficiency, so as to ensure beautiful appearance and improve Production efficiency and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with each accompanying drawing, the present invention is described in detail.

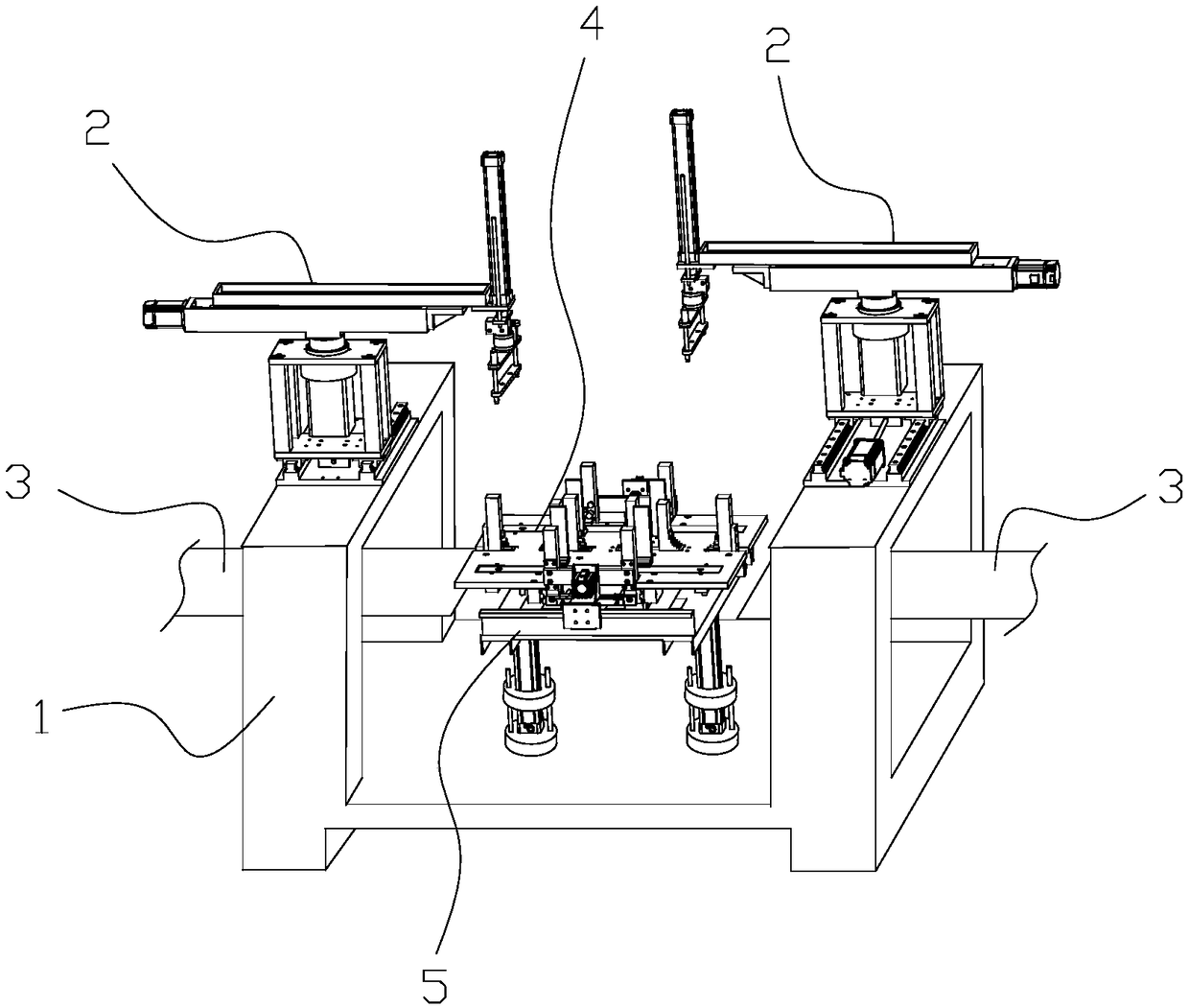

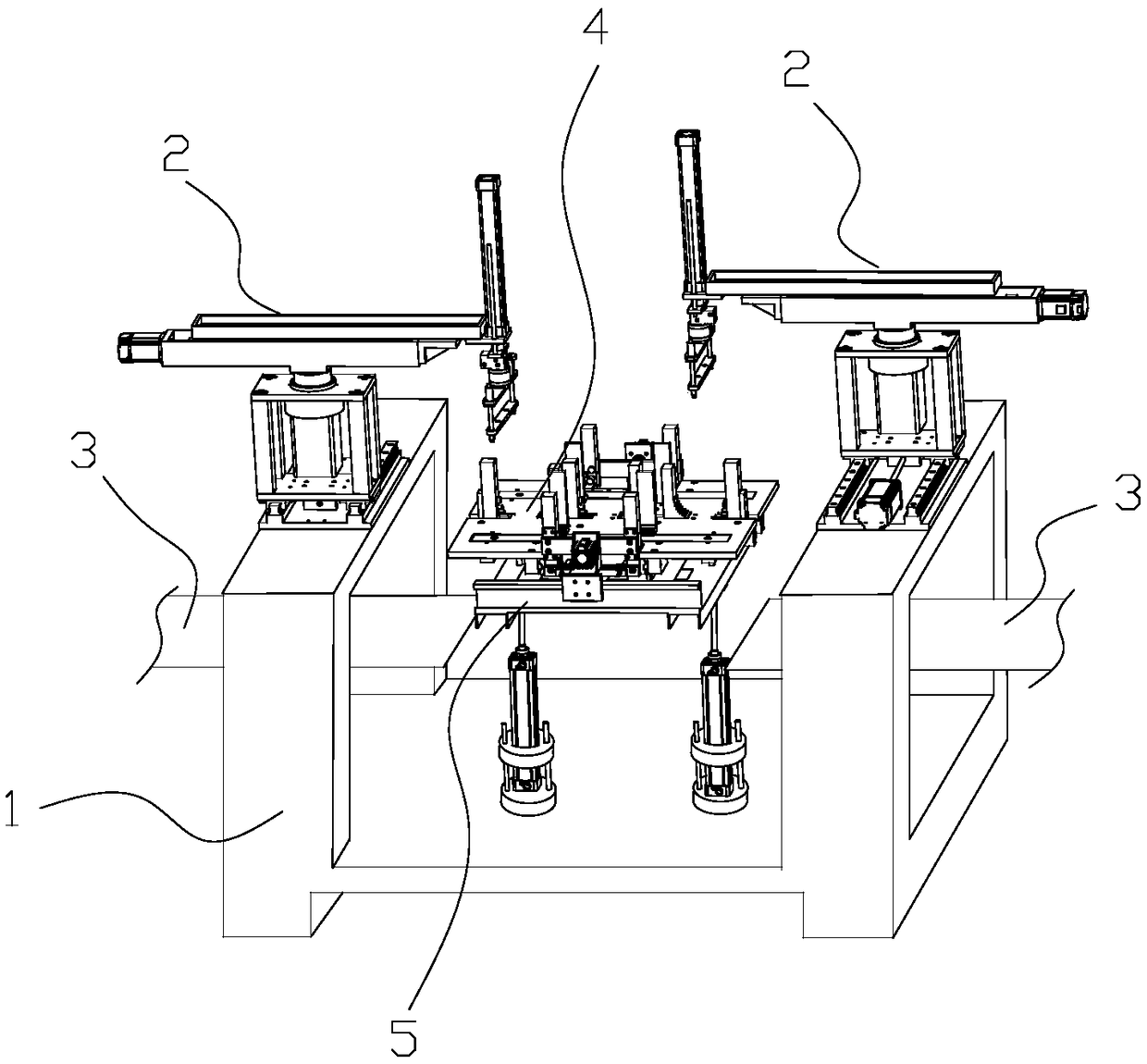

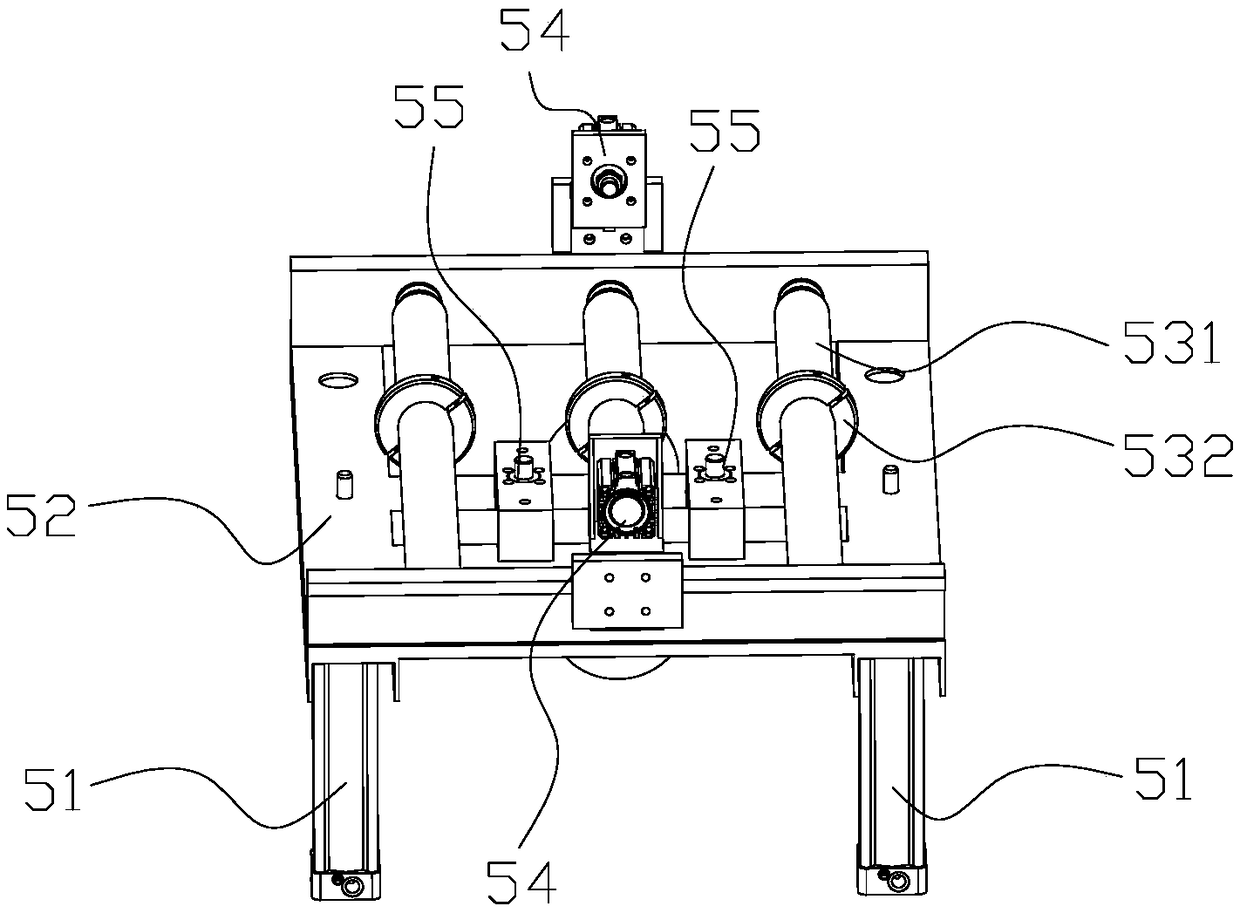

[0034] to combine figure 1 with figure 2 , the automatic lamination device of the present invention includes a support 1 , a pick-and-place mechanism, a transmission mechanism 3 , a lamination platform 4 and a lifting mechanism 5 , preferably, the pick-and-place mechanism is a five-axis manipulator 2 . A five-axis manipulator 2 is installed on the two installation platforms of the bracket 1, and a lifting mechanism 5 is installed between the two installation platforms. The lamination platform 4 is placed on the lifting mechanism 5, and the transmission mechanism 3 is used for feeding In order to stack the lamination platform 4 of the silicon steel sheet and send out the lamination platform 4 of the silicon steel sheet, the transmission mechanism 3 passes through the through hole of the mounting platform of the support 1 and is connected with the lifting mechanism 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com