Integrally formed inductor and manufacture process thereof

An inductor and integrated technology, applied in the field of inductors, can solve the problems that affect the overall size and overall appearance of the inductor, affect the normal connection, and have no fixed structure, so as to achieve better connection quality, ensure the appearance size and aesthetics, size, etc. The effect of better control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

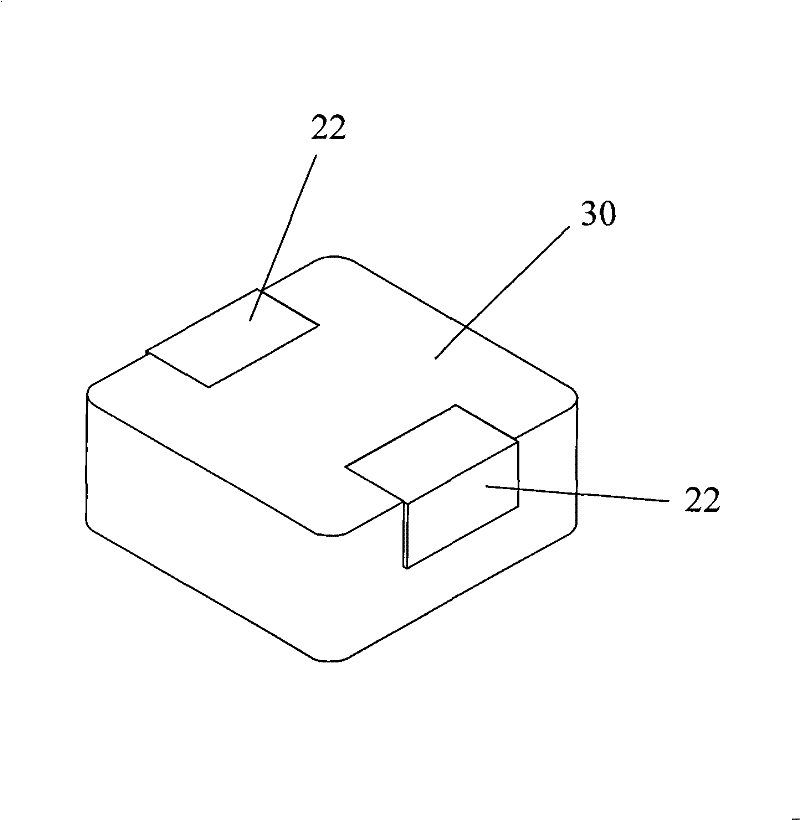

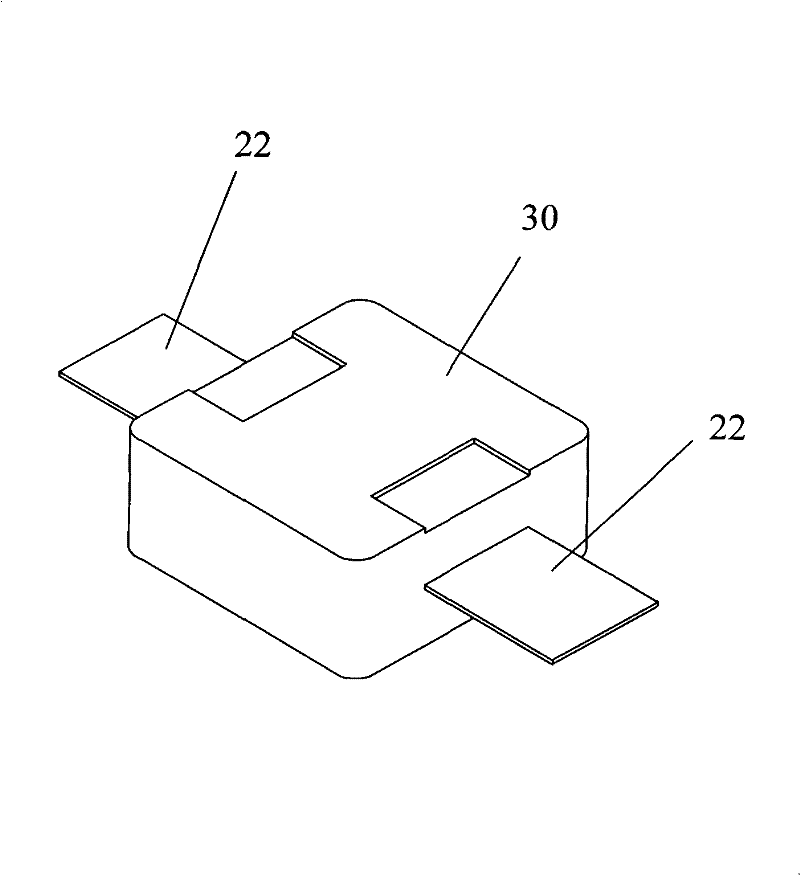

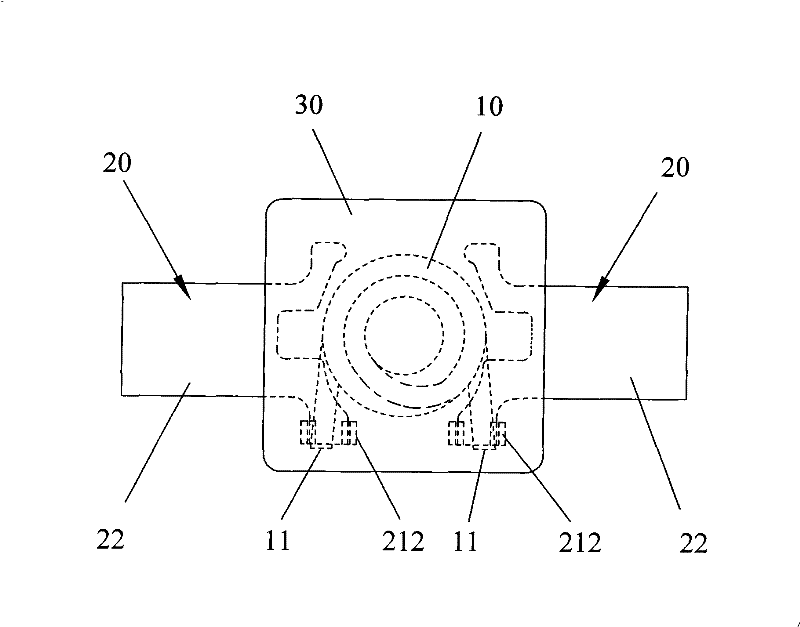

[0047] First, please refer to Figure 1 to Figure 4As shown, it shows the specific structure of the preferred embodiment of the present invention, including a coil 10, two electrode feet 20 and a magnetic solid body 30 made by pressing powder molding, and the coil 10 is embedded in the magnetic solid body 30 Inside, the first ends 21 of the two electrode feet 20 are embedded in the magnetic solid body 30 to maintain an electrical gap and are electrically connected to the two pins 11 of the coil 10, and the second ends 22 of the two electrode feet 20 extend out of the magnetic solid body. The body 30 is bent and tightly attached to the surface of the magnetic solid body 30 . The material of the magnetic solid body 30 can be soft magnetic alloy powder or insulating iron powder.

[0048] Such as Figure 4 and combine image 3 , the electrode foot 20 is a sheet-like structure, the middle of the first end 21 of the electrode foot 20 is provided with a positioning notch 215, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com