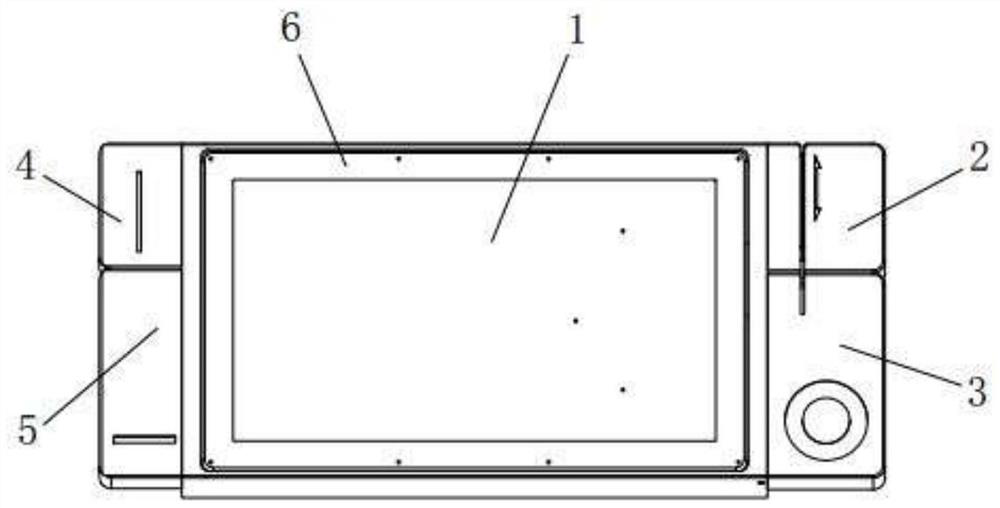

Modularized assembling mechanism

An assembly mechanism, modular technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of hardware cost waste, and achieve the effect of simple and convenient installation, saving production costs, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

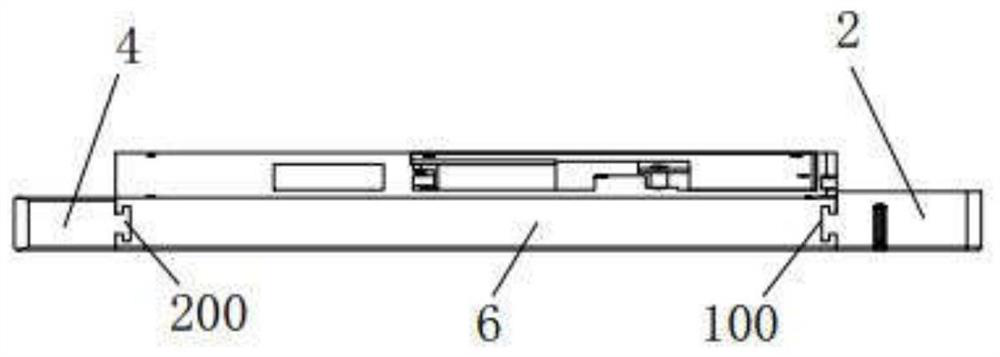

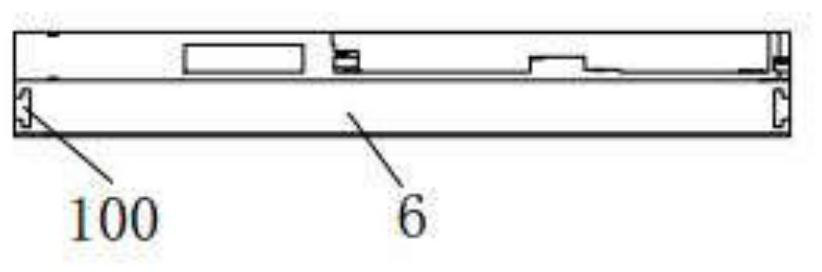

[0035] When the customer needs to use the ID card identification module and card reader module, the convex platform A of the ID card identification module shell can be slowly drawn in through the concave track of the screen shell until there is a plane below to block the ID card identification module shell. Sliding downwards, at this time, through the threaded through hole, screws are screwed in from the inside of the ID card identification module housing and against the bottom surface of the concave track, the ID card identification module housing is fixed on the screen housing, and the ID card identification module of the prior art The main body of the part is installed in the housing of the ID card identification module, and the main body of the ID card identification part is connected to the large operating screen through the threading groove and the threading hole, and then it can be covered with a decorative cover, and then the card reader can be installed in the same way....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com