Separated floor scrubber

A floor washing machine and separate technology, which is applied in the field of floor washing machines, can solve the problems that the sewage tank cannot be disassembled, which is unfavorable for the access and maintenance of the motor, and achieves the effect of convenient access and maintenance, and preventing it from being wetted by water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

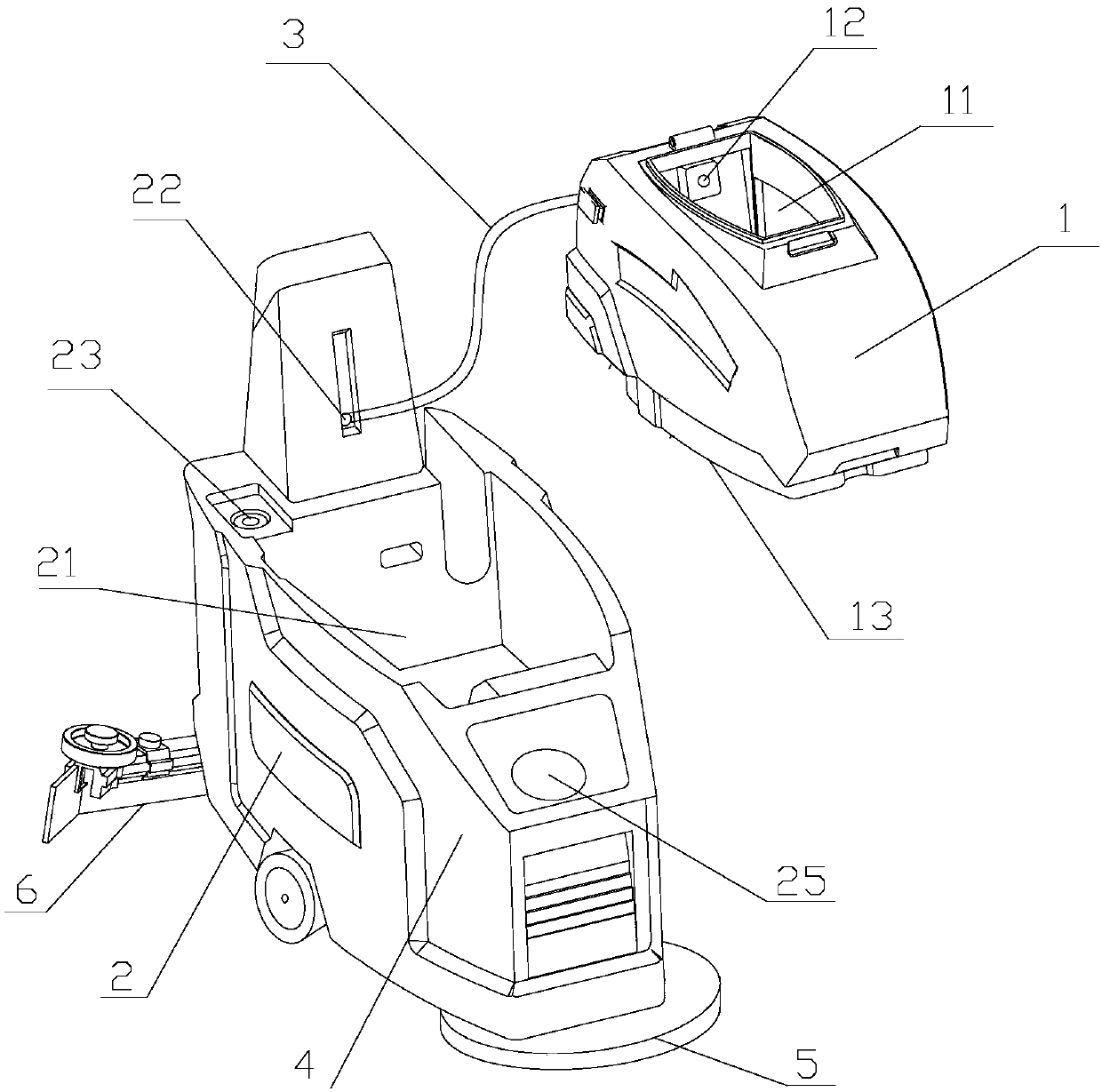

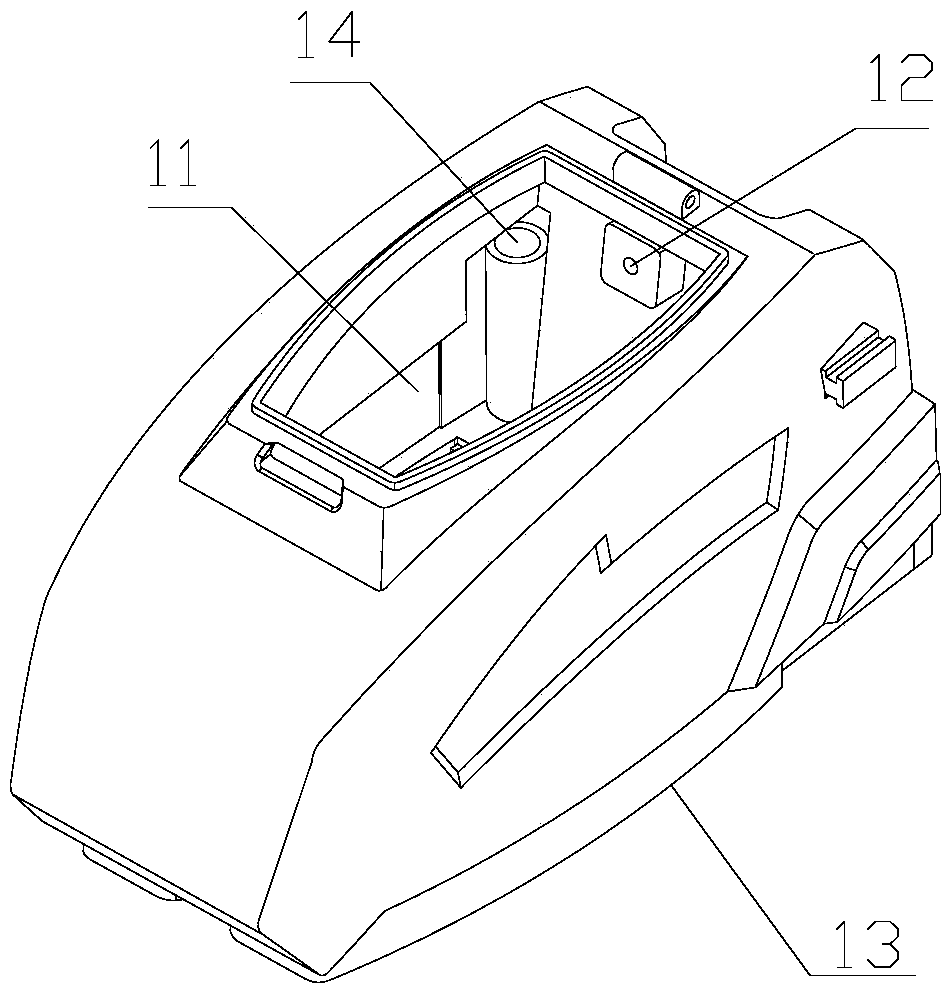

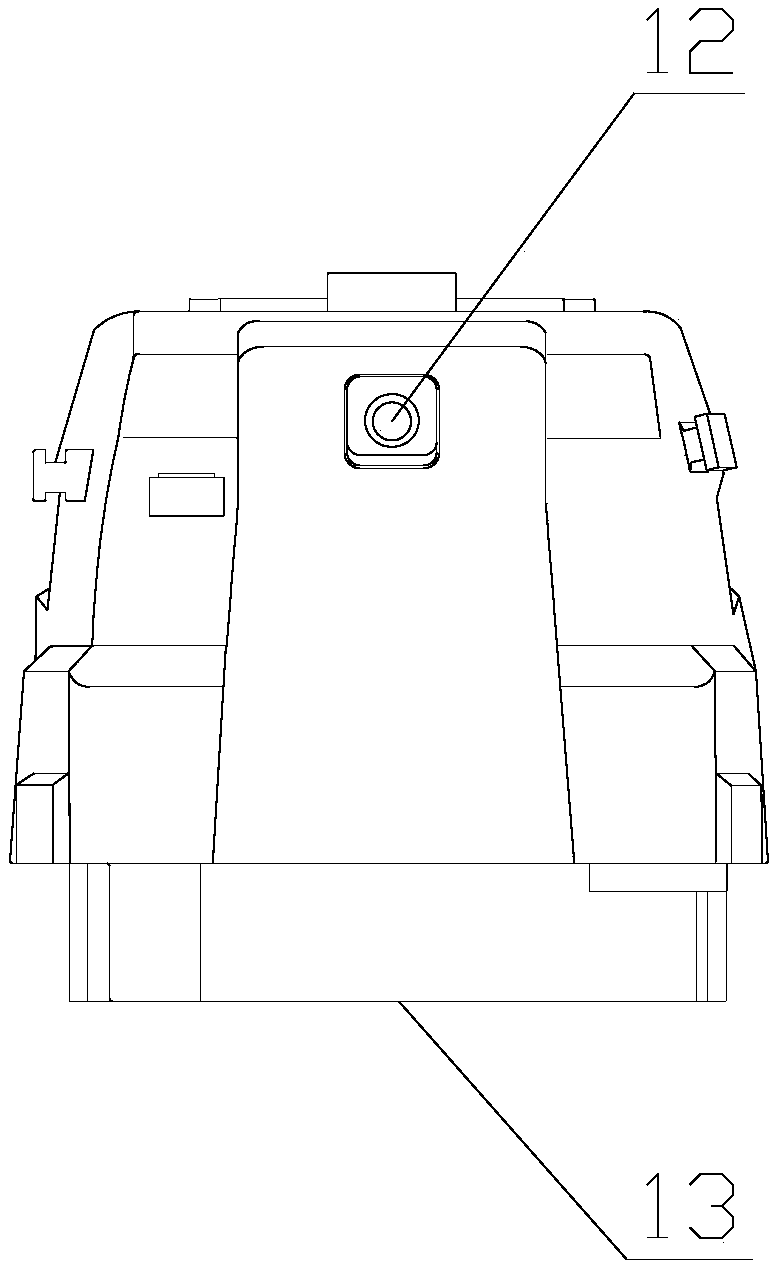

[0026] As shown in the drawings, a separate floor washing machine includes a sewage tank 1, a clean water tank 2, a suction motor, a sewage collection strip 6, and a sweeping plate 5 with several water outlets on the bottom surface. The sewage collection strip 6 passes through The sewage pipe is connected to the sewage tank 1; the sewage tank 1 is located above the clean water tank 2, and the sewage tank 1 is detachably connected to the clean water tank 2; the clean water tank 2 is provided with a clean water storage chamber 4 and a motor chamber 21; the motor chamber 21 is located inside the clean water tank 2, and the suction motor is located in the motor chamber 21; the inner wall of the motor chamber 21 and the outer wall of the clean water tank 2 form a sandwich structure, and the sandwich structure A clean water storage chamber 4 is formed; the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com