A rail vehicle wheel that damps and muffles noise

A rail vehicle and wheel technology, applied in the field of rail vehicles, can solve the problems of reducing, surrounding environment and people's injuries, and affecting passengers' riding experience, and achieves the effects of reducing and eliminating noise, easy implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

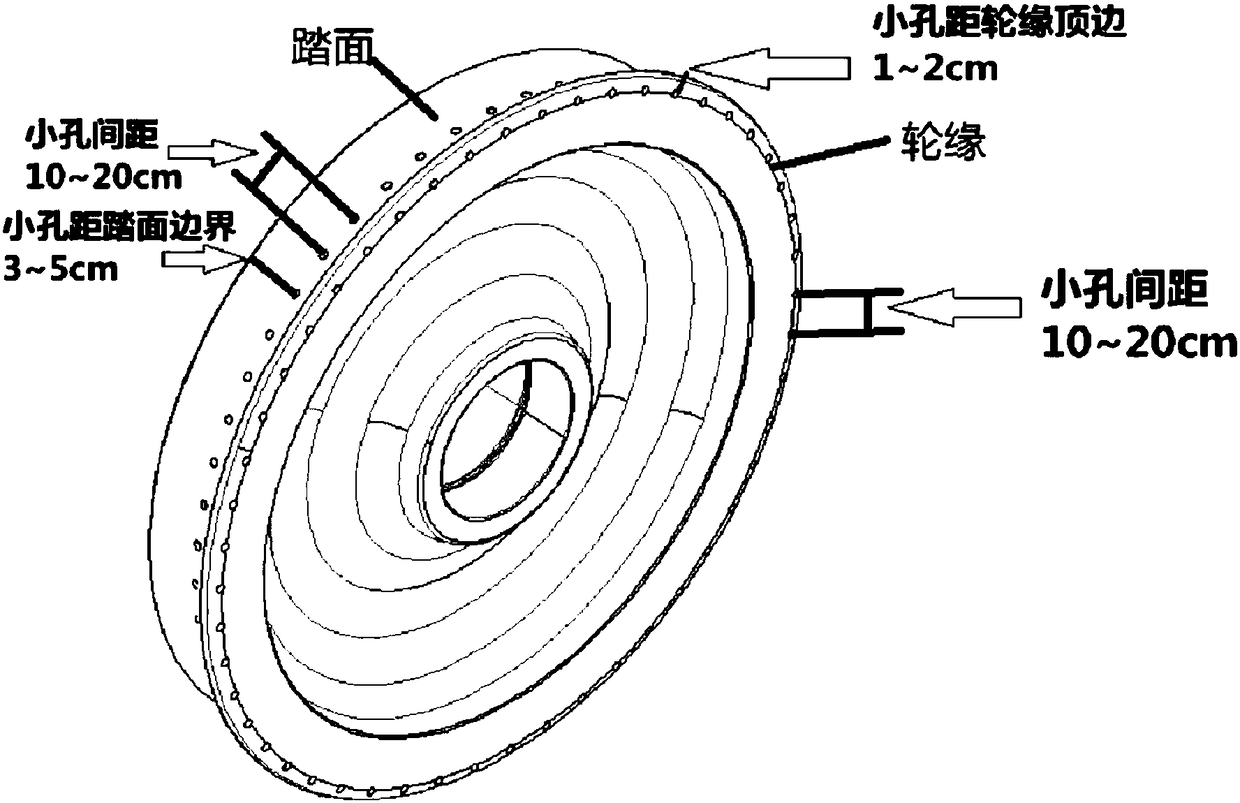

[0010] Such as figure 1 As shown, a rail vehicle wheel that can reduce vibration and eliminate noise includes a wheel body. The outer periphery of the wheel body is provided with a tread surface and a rim on one side of the tread surface. There are multiple rim holes; both the tread holes and the interior of the rim holes are fitted with rubber. Wherein, the diameter of the tread hole is 3mm-5mm, and the diameter of the rim hole is 3mm-5mm.

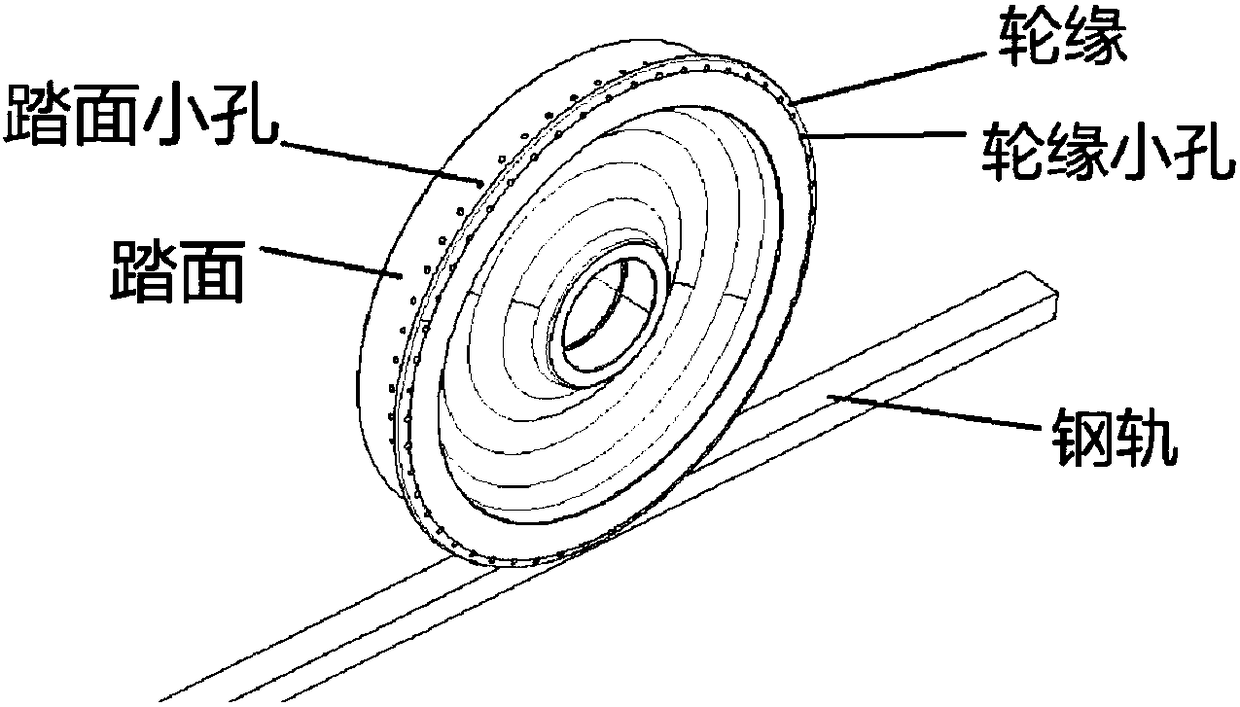

[0011] Such as figure 2 As shown, the wheel is rolling on the track, the tread and the rim are in contact with the rail, and the tread and the rim are deformed under force. Since the wheel rim and the tread have small holes, the vibration and energy absorption can be reduced and eliminated by increasing the deformation amount. The noise generated by wheel-rail contact friction and vibration; at the same time, it deforms and squeezes the rubber material inside the small hole, and uses its elastic damping characteristics to absorb energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com