A locomotive cooling chamber modular design

A cooling chamber and modular technology, applied in locomotives and other directions, can solve the problems of increasing manufacturing, total assembly and maintenance difficulty and cost, the locomotive cooling chamber has not achieved modular integrated design, and cannot be hoisted in place at one time, so as to ensure safety. Efficient operation, reduced maintenance costs, simplified manufacturing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

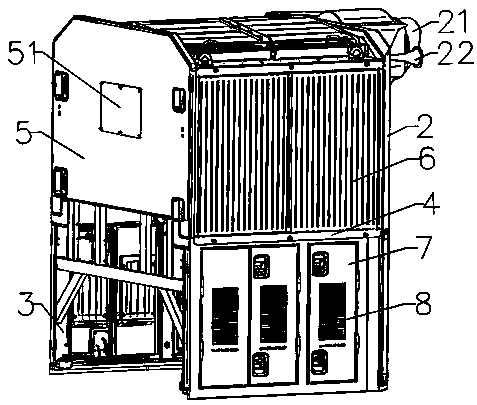

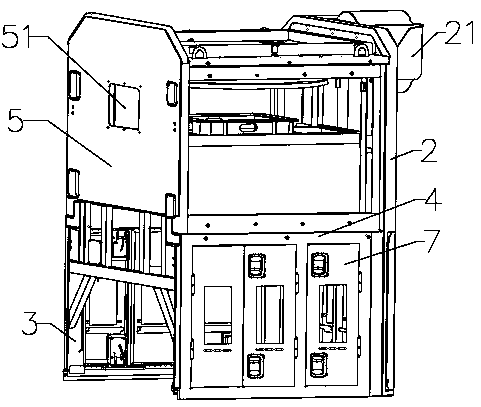

[0026] The present invention proposes a novel modular locomotive cooling chamber, such as figure 1 and figure 2 As shown, it includes a cooling chamber steel structure and a cooling device 1. The cooling device 1 is installed in the cooling chamber steel structure. The cooling chamber steel structure includes a front wall 2, a left side wall 3, a right side wall 4 and a partition wall 5. The front end wall 2, The left side wall 3, the right side wall 4 and the partition wall 5 are fixedly connected together.

[0027] Specifically, an anti-wind and sand air filter 6 is provided above the left side wall 3 and the right side wall 4, and an inspection door 7 is provided below the left side wall 3 and the right side wall 4, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com