Conveyor belt tensioning device

A technology of tensioning mechanism and conveyor belt, which is applied in the field of agricultural machinery, can solve the problems of unsightly exposure of the adjustment mechanism, affect the quality of conveying, and inconvenient adjustment, etc., and achieve consistent tension, not easy to deviate, and good force consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

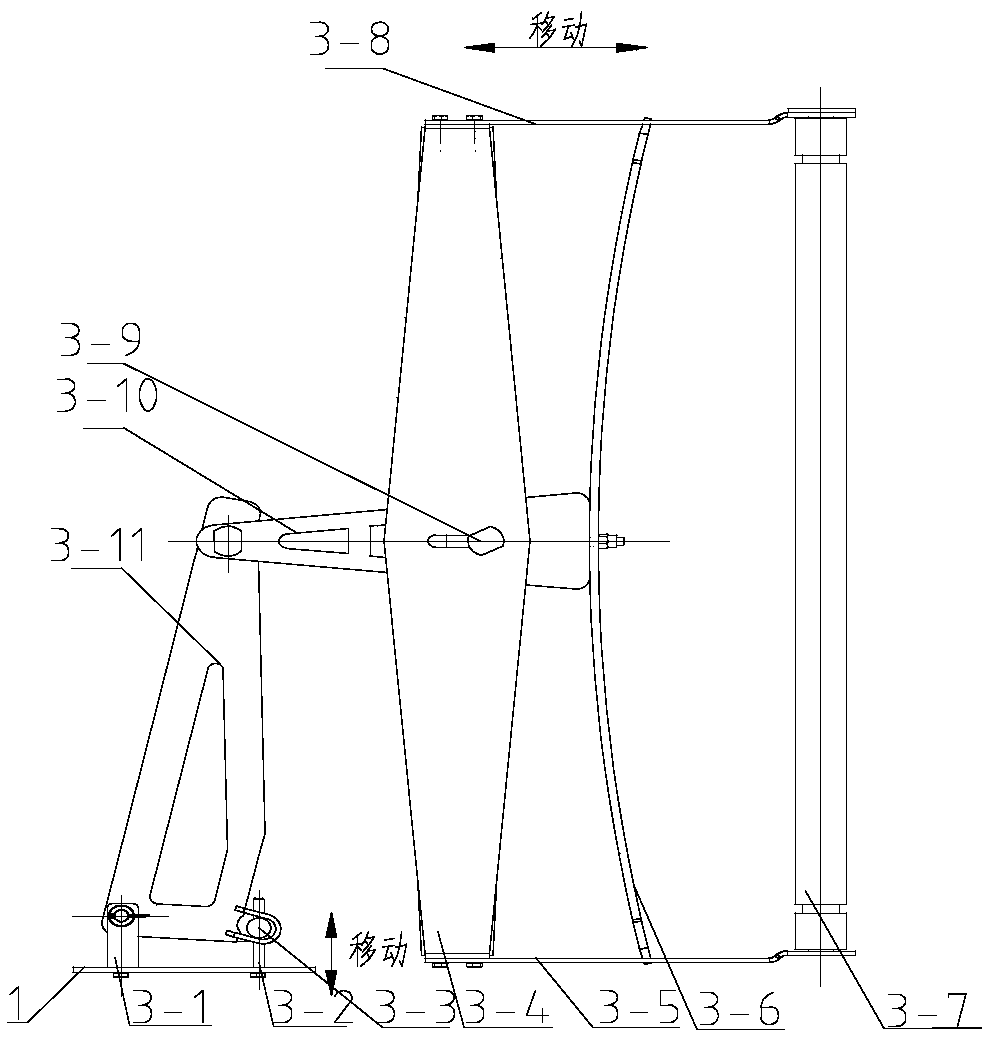

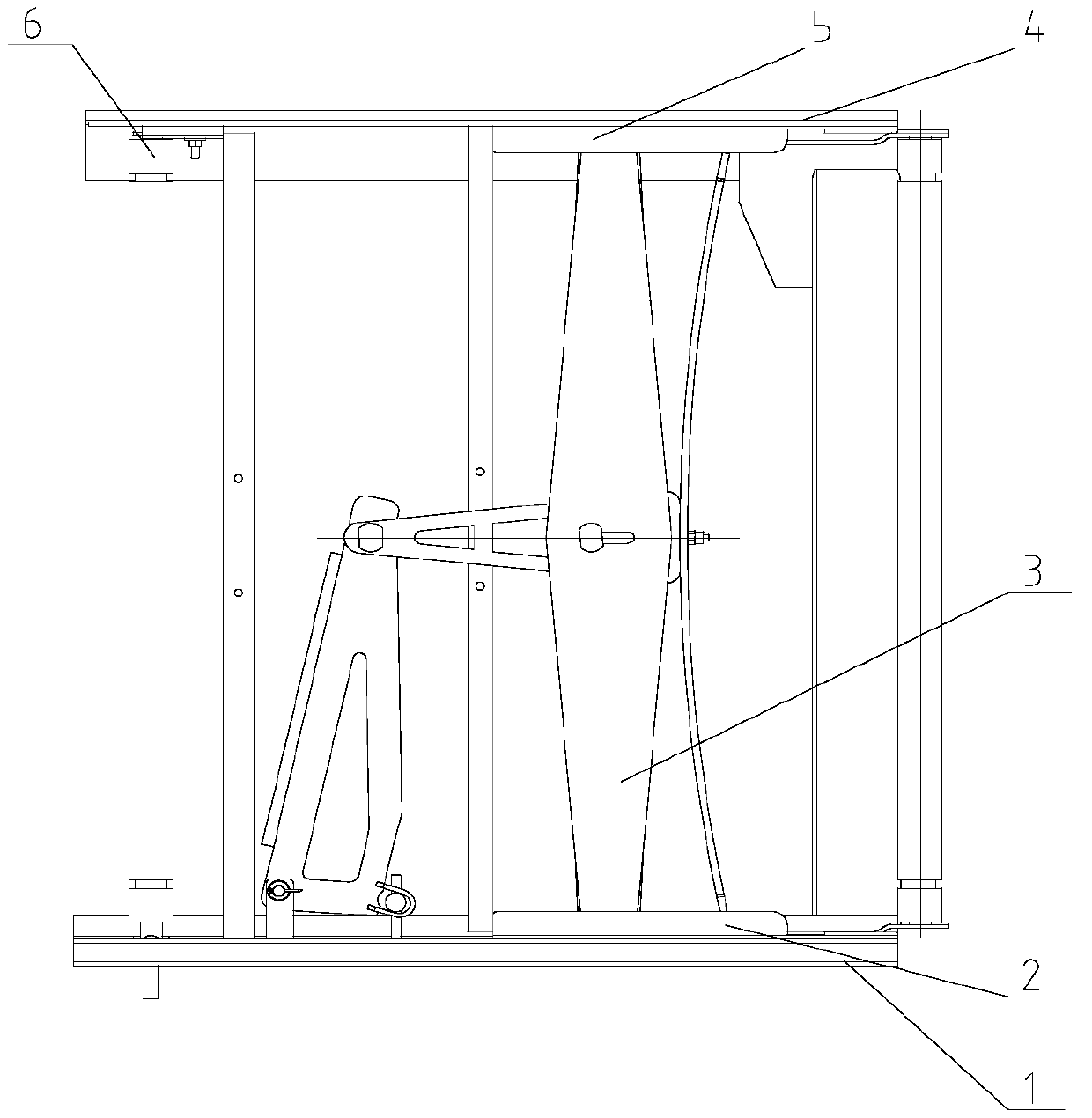

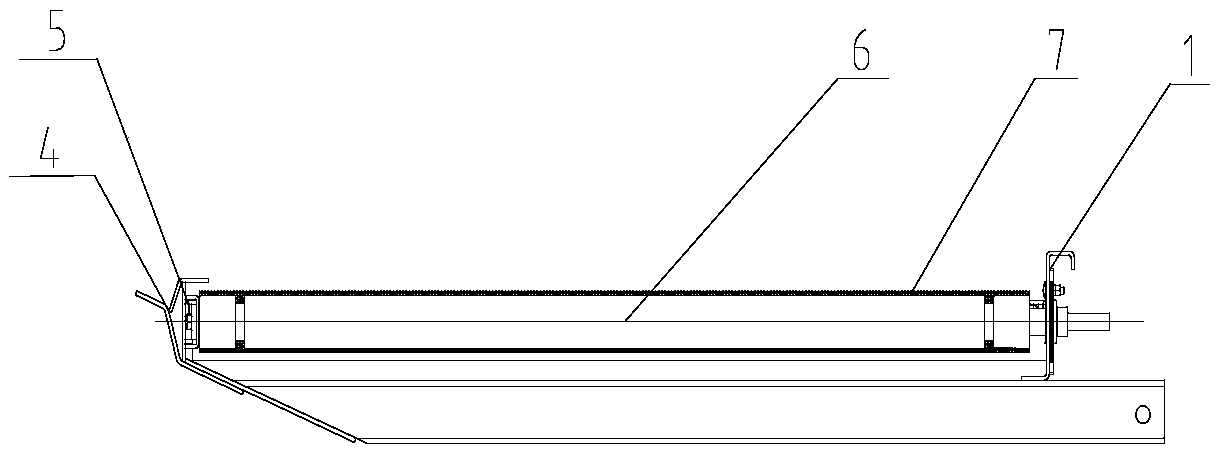

[0020] The present invention is a conveyor belt tensioning mechanism with simple structure and low cost, which can self-adaptively adjust the tension force of the tensioning mechanism, see Figure 1-4 , including a first frame 4 and a second frame 1 arranged in parallel, a circle of conveyor belt 7 surrounds the first frame and the second frame, and a first guide groove 5 is provided on the opposite inner side of the first frame 4 and the second frame 1 and the second guide groove 2, the conveyor belt driving shaft 6 is fixed between the first frame 4 and the second frame 1, and the first side bracket plates 3-8 are slidingly arranged in the first guide groove 5 and the second guide groove 2 respectively. and the second side support plate 3-5, between the first side support plate 3-8 and the second side support plate 3-8, the conveyor belt driven shaft 3-7 is fixed at the end away from the conveyor belt driving shaft 6, An elastic tensioning mechanism 3 for adjusting the tensi...

Embodiment 2

[0023] For this example see Figure 5 , the difference from Example 1 is that in Example 1, the elastic steel plate is replaced by a rigid steel plate 3-12, and the adjusting end is fixed with a linear motor 3-14 through a fixing seat, and the linear motor 3-14 is connected to the conveyor through a controller. With a pressure sensor 3-13 on the driven shaft 3-7. The pressure sensor 3-13 is fixed on the supporting shaft of the driven shaft to obtain the pressure of the driven shaft on the driven shaft by the conveyor belt in real time.

[0024] When the pressure sensor 3-13 detects that the pressure of the driven shaft is less than the tension range required for the tension of the conveyor belt, the linear motor 3-14 adjusts the length of the threaded pull rod 3-2, pulls the adjustment end to change the swing arm angle, and drives The driven shaft moves in the guide groove, thereby changing the tension.

[0025] When the pressure sensor detects that the pressure on the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com