Polyurethane modified calcium alginate gel microballoon and preparation method thereof

A polyurethane modification, calcium alginate technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the loss of crystal grains, affect the stability of gel materials, and lack of covalent bond between crystal grains and polymer substrates and other problems, to achieve the effect of reducing consumption and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

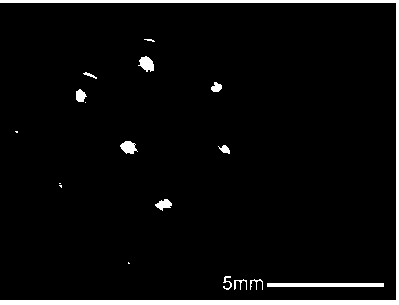

Image

Examples

Embodiment 1

[0046] Raw materials: isophorone diisocyanate (IPDI); diethylene glycol (diethylene glycol, DEG); hydroxyethyl methacrylate (HEMA);

[0047] Experimental steps: (molar ratio IPDI:HEMA:DEG=1:1:1.2)

[0048] (1) Weigh (0.5563 g) IPDI and place it in a constant temperature water bath (35°C), N 2 environment, add 2 drops of DBTDL, stir magnetically for 2 minutes, slowly add (0.3359 g) HEMA to it, and react for 55 minutes;

[0049] (2) Raise the temperature to 50°C, slowly add the reaction product of IPDI and HEMA into 0.3170 g of DEG dropwise (strictly control the dropping speed), and react at constant temperature for 1 hour;

[0050] (3) After reacting for 1 hour, add a certain volume of acetone to dissolve to obtain a prepolymer solution.

Embodiment 2

[0052] Raw materials: isophorone diisocyanate (IPDI); dimethylolpropionic acid (DMAP); hydroxyethyl methacrylate (HEMA);

[0053] Experimental steps: (molar ratio IPDI:HEMA:DMAP=1:1:1.2)

[0054] (1) Weigh (0.5591g) IPDI and place it in a constant temperature water bath (35°C), N 2 environment, add 2 drops of DBTDL, stir magnetically for 2 minutes, slowly add (0.3410 g) HEMA to it, and react for 55 minutes;

[0055] (2) Dissolve 0.3359 g of DMAP in 3 ml of DMF;

[0056] (3) Raise the temperature to 80°C, add the reaction product of IPDI and HEMA slowly (strictly control the dropping speed) dropwise into DMAP, and react at constant temperature for 85 minutes.

Embodiment 3

[0058] Raw materials: isophorone diisocyanate (IPDI); polyethylene glycol (1000) (PEG); hydroxyethyl methacrylate (HEMA);

[0059] Experimental steps: (molar ratio IPDI:HEMA:PEG=1:1:1.2)

[0060] (1) Weigh (1.1474g) IPDI and place it in a constant temperature water bath (35°C), N 2 environment, add 2 drops of DBTDL, stir magnetically for 2 minutes, slowly add (0.6874 g) HEMA to it, and react for 55 minutes;

[0061] (2) Take a certain volume of acetone to dissolve 5.1403 grams of PEG;

[0062] (3) Raise the temperature to 80°C, add the reaction product of IPDI and HEMA slowly (strictly control the dropping speed) into PEG dropwise, and react at constant temperature for 85 minutes.

[0063] The second step: calcium alginate graft modification, there are two schemes

[0064] plan 1

[0065] Pre-polymerization-gelating (pre-polymerization-gelating, PPG)

[0066] Add 30~250g of deionized water into a three-necked flask immersed in a magnetic stirring constant temperature wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com