A kind of expansion anti-crack waterproofing agent and using method thereof

A technology of anti-crack waterproofing agent and expansion agent, applied in the field of expansion anti-cracking waterproofing agent, can solve the problems of large slump loss of concrete, shortened setting time, poor dispersibility, etc., improve durability and speed up early reaction rate , make up for the negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

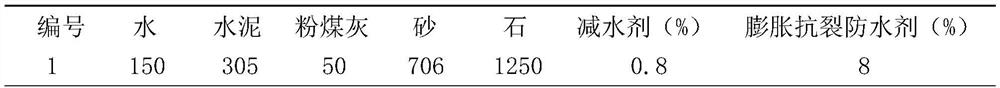

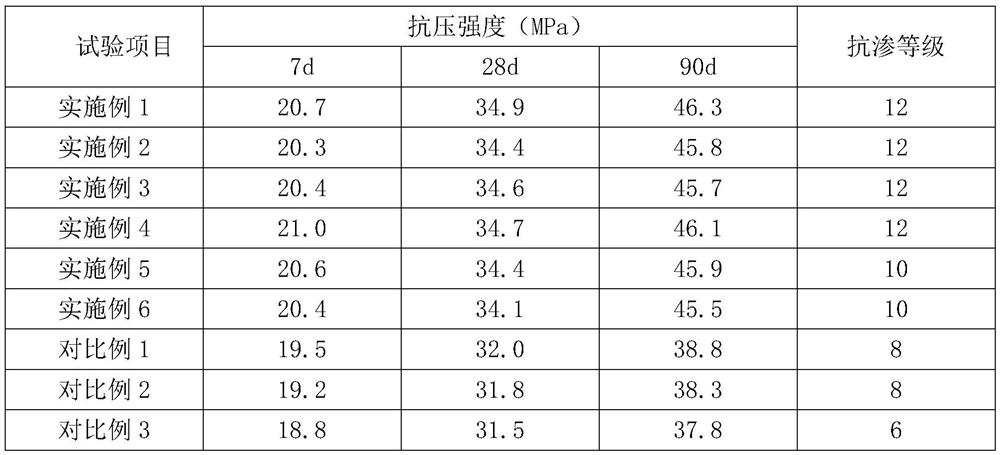

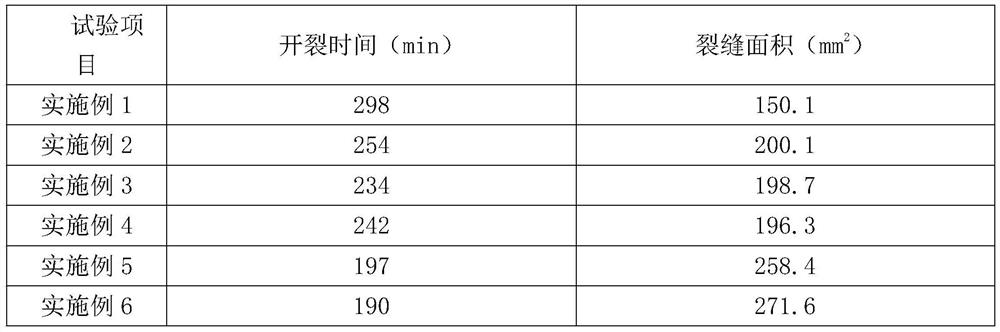

Examples

Embodiment 1

[0034] This embodiment provides an expanded anti-crack water repellent, including the following mass percentage of raw materials: 30% microscopy, 30% microbeads, 35% coal gangue, 3% of the modified basalt fiber, 2% of additives;

[0035] When the mass ratio of the anti-cleavage expansion agent and the modified basalt fiber is 10: 1, the anti-crack waterproof performance of concrete is optimal.

[0036] The method of preparing the anti-crack expansion agent is as follows: After mixing the expansion agent, the epoxy resin, the amino resin is mixed with mass ratio of 95: 4: 1, dissolved in anhydrous ethanol solution, stirred well for 10 min, placed in a vacuum of 60 ° C. The drying tank is vacuum dried to remove anhydrous ethanol to obtain a solid mixture, and the anti-crack expansion agent is obtained by the powder;

[0037] The expansion agent is composed of a calcium oxide expansionizer and a sulfoside expansion agent having a mass ratio of 9: 1, and calcium oxide or calcium hydro...

Embodiment 2

[0050] This embodiment provides an expanded anti-crack water repellent, compared to Example 1, in that the anti-crack expansion agent 5%, microbeads 40%, coal gangue 45%, modified basalt fiber 8%, unpack 2%. The test method was tested in Example 1, and the test results were shown in Table 2, and Table 3 was shown.

Embodiment 3

[0052] This embodiment provides an expanded anti-crack water repellent, compared to Example 1, the anti-crack expansion agent 20%, microbeads 38%, coal gangue 40%, modified basalt fiber 0.1%, unplexer 1.9%. The test method was tested in Example 1, and the test results were shown in Table 2, and Table 3 was shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com