Expansion crack water-proofing agent and using method thereof

A technology of anti-cracking waterproofing agent and expansion agent, which is applied in the field of expansion anti-cracking waterproofing agent, which can solve the problems of large slump loss, shortened setting time, and poor dispersion of concrete, so as to improve compactness and reduce water migration , The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

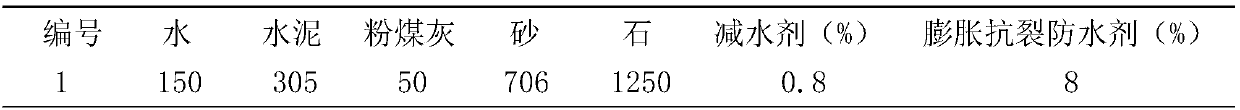

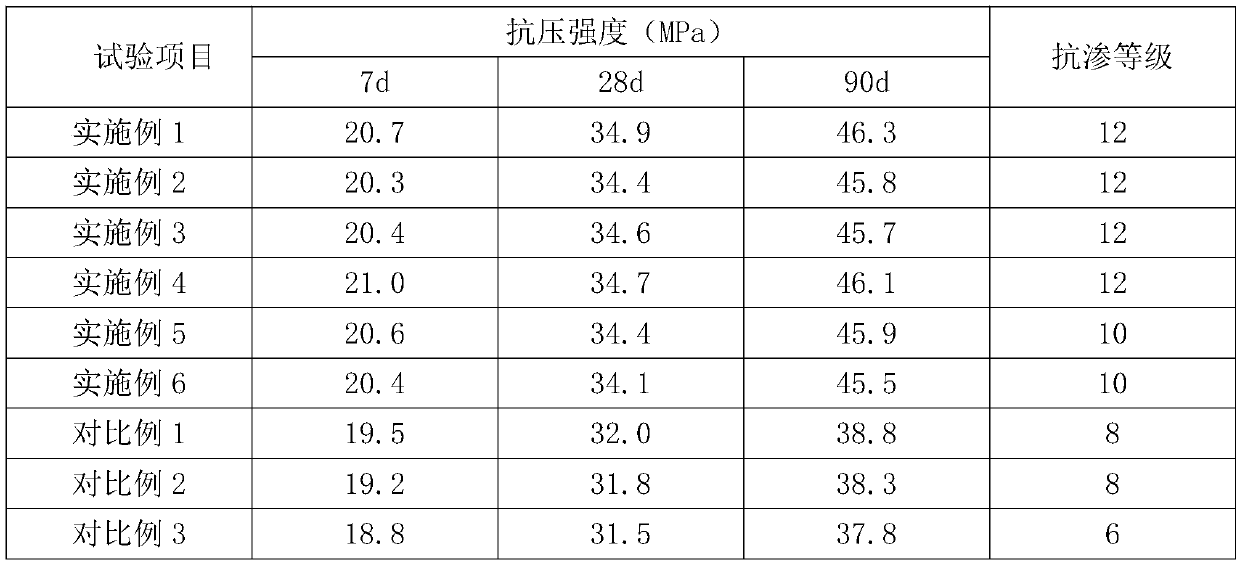

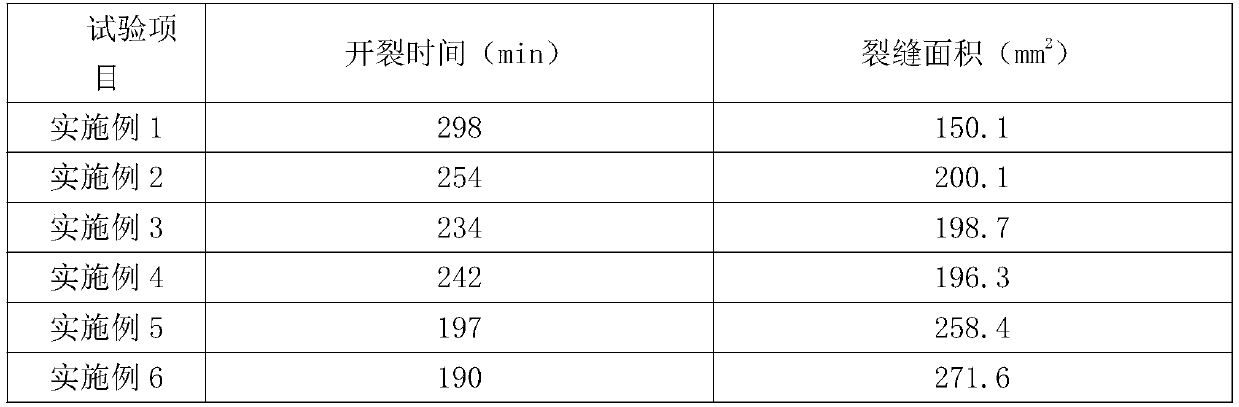

Examples

Embodiment 1

[0034] This embodiment provides an expansion anti-crack waterproofing agent, which contains the following raw materials in mass percentage: 30% of anti-crack expansion agent, 30% of microbeads, 35% of coal gangue, 3% of modified basalt fiber, and 2% of admixture;

[0035] When the mass ratio of anti-crack expansion agent and modified basalt fiber is 10:1, the anti-crack and waterproof performance of concrete is optimal.

[0036] The preparation method of the anti-crack expansion agent is as follows: after mixing the expansion agent, epoxy resin and amino resin according to the mass ratio of 95:4:1, dissolve them in anhydrous ethanol solution, stir them evenly for 10 minutes, and place them in a vacuum at 60°C. Vacuum-dry in a drying oven to remove absolute ethanol to obtain a solid mixture, which is ground to obtain an anti-crack expansion agent;

[0037] The expansion agent is composed of a calcium oxide expansion agent and a calcium sulfoaluminate expansion agent with a mass...

Embodiment 2

[0050] This embodiment provides an expansion anti-crack waterproofing agent. Compared with Example 1, the difference is that the anti-crack expansion agent is 5%, microbeads are 40%, coal gangue is 45%, modified basalt fiber is 8%, and additives 2%. The test method in Example 1 is used to test, and the test results are shown in Table 2 and Table 3.

Embodiment 3

[0052] This embodiment provides an expansion anti-crack waterproofing agent. Compared with Example 1, the difference is that the anti-crack expansion agent is 20%, microbeads are 38%, coal gangue is 40%, modified basalt fiber is 0.1%, and additives 1.9%. The test method in Example 1 is used to test, and the test results are shown in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com