A kind of high-efficiency self-compensating hydration heat regulator and preparation method and application thereof

A technology of self-compensation and heat of hydration, which is applied in the field of functional additives for building materials, can solve the problems that the cleavage of massive aggregates affects the strength of concrete, the location of cracks, the time is different, and cannot be fully released, so as to improve the mechanical properties, Ease of use, high efficiency, and the effect of preventing temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

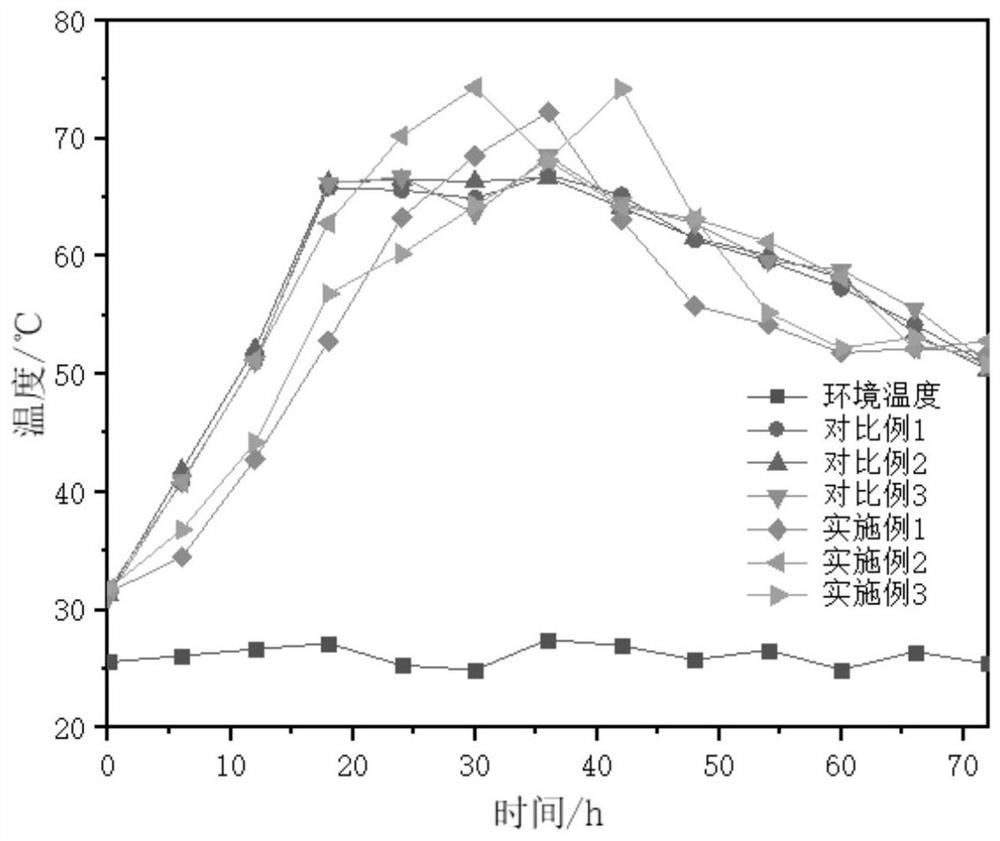

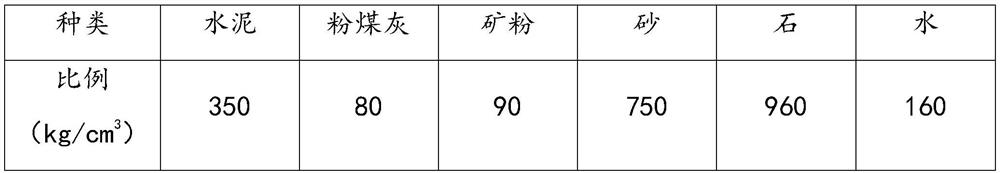

Embodiment 1

[0034] A high-efficiency self-compensating hydration heat regulator, its components and the mass fraction of each component are:

[0035] 85 parts of starch, 10 parts of phase change material, 3 parts of amylase;

[0036] The starch is a mixture of wheat starch, corn starch, potato starch and tapioca starch with a mass ratio of 1:1:1:1;

[0037] The phase change material is a paraffin type phase change material, the number of carbon atoms is 30-40, the melting point is 65-80°C, and it is in powder form;

[0038] Amylase is α-amylase and saccharification enzyme at 65℃, and the ratio of enzyme amount is 1:2~1:3;

[0039] The specific preparation steps are:

[0040] Weigh starch, phase change material and amylase in proportion;

[0041] Add a small amount of hydrogen peroxide, starch mixture, a small amount of sodium hydroxide diluent, a certain amount of water, and 10% borax solution into the reaction kettle in turn, stir for 30 minutes, and refrigerate the gelatinized starch...

Embodiment 2

[0045] A high-efficiency self-compensating hydration heat regulator, its components and the mass fraction of each component are:

[0046] 80 parts of starch, 12 parts of phase change material, 4 parts of amylase;

[0047] The starch is a mixture of wheat starch, corn starch, potato starch and tapioca starch with a mass ratio of 1:1:1:1;

[0048] The phase change material is a paraffin type phase change material, the number of carbon atoms is 30-40, the melting point is 65-80°C, and it is in powder form;

[0049] Amylase is α-amylase and saccharification enzyme at 65℃, and the ratio of enzyme amount is 1:2~1:3;

[0050] The specific preparation steps are:

[0051] Weigh starch, phase change material and amylase in proportion;

[0052] Add a small amount of hydrogen peroxide, starch mixture, a small amount of sodium hydroxide diluent, a certain amount of water, and 10% borax solution into the reaction kettle in turn, stir for 30 minutes, and refrigerate the gelatinized starch...

Embodiment 3

[0056] A high-efficiency self-compensating hydration heat regulator, its components and the mass fraction of each component are:

[0057]75 parts of starch, 15 parts of phase change material, 5 parts of amylase;

[0058] The starch is a mixture of wheat starch, corn starch, potato starch and tapioca starch with a mass ratio of 1:1:1:1;

[0059] The phase change material is a paraffin type phase change material, the number of carbon atoms is 30-40, the melting point is 65-80°C, and it is in powder form;

[0060] Amylase is α-amylase and saccharification enzyme at 65℃, and the ratio of enzyme amount is 1:2~1:3;

[0061] The specific preparation steps are:

[0062] Weigh starch, phase change material and amylase in proportion;

[0063] Add a small amount of hydrogen peroxide, starch mixture, a small amount of sodium hydroxide diluent, a certain amount of water, and 10% borax solution into the reaction kettle in turn, stir for 30 minutes, and refrigerate the gelatinized starch;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com