A modified calcium oxide cement concrete expansion agent and its preparation method

A technology of cement concrete and calcium oxide, which is applied in the field of concrete building materials, can solve the problems of easy moisture absorption of expansion clinker, increase of effective expansion energy, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a modified calcium oxide cement concrete expansion agent. The expansion agent is composed of phenolic resin, modified rosin resin, and calcium oxide expansion clinker. The phenolic resin and modified rosin resin work together to wrap the The surface of the calcium oxide-based expanded clinker, wherein the phenolic resin and modified rosin resin account for 5% of the total mass of the modified calcium oxide-based cement concrete expansion agent.

[0032] The mass ratio of the phenolic resin and the modified rosin resin is 10:1; the specific surface area of the modified calcium oxide cement concrete expansion agent is 800m 2 / kg;

[0033] The preparation method of the modified rosin resin comprises the following steps: under an inert atmosphere, mix the rosin resin and fatty alcohol polyoxyethylene ether sodium sulfate according to the above-mentioned mass ratio, react at 250° C. for 5 hours, and keep a vacuum degree of 0 after the reaction is c...

Embodiment 2

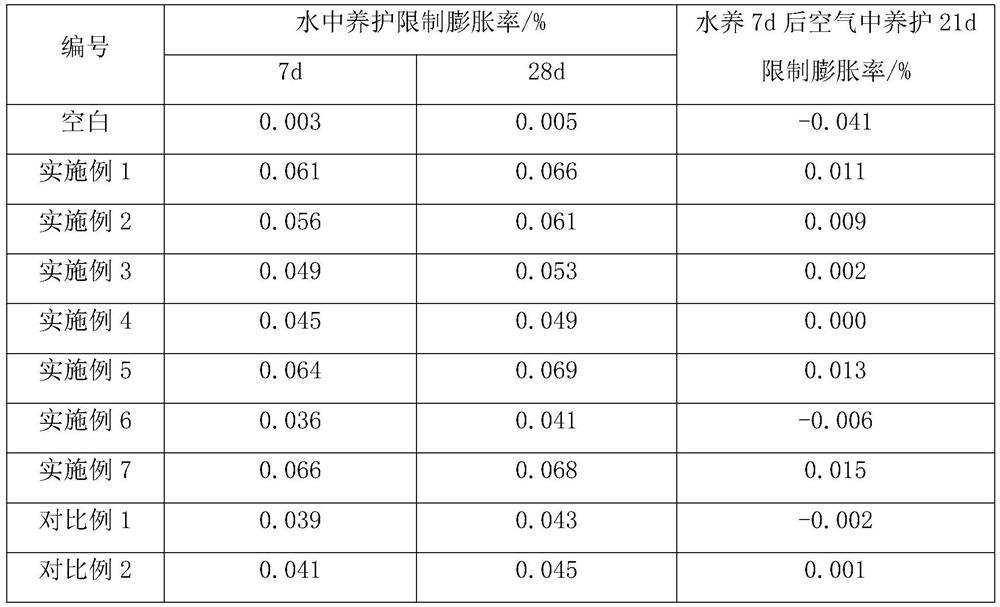

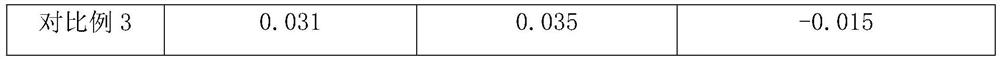

[0041] This embodiment provides a modified calcium oxide cement concrete expansion agent. Compared with Embodiment 1, the difference is that the mass ratio of the phenolic resin and the modified rosin resin is 5:1; The modified calcium oxide cement concrete expansion agent was prepared by the above-mentioned preparation method, and the test method described in Example 1 was used for testing, and the test results are shown in Table 2.

Embodiment 3

[0043] The present embodiment provides a modified calcium oxide cement concrete expansion agent, compared with embodiment 1, the difference is that the mass ratio of the rosin resin to fatty alcohol polyoxyethylene ether sodium sulfate is 5:1; The modified calcium oxide cement concrete expansion agent was prepared by the preparation method described in Example 1, and the test method described in Example 1 was used for testing, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com