A kind of expansion fiber anti-crack waterproof agent

A technology of anti-crack waterproofing agent and expanded fiber, which is applied in the field of building materials, can solve the problems of low flexural strength, low anti-seepage level and anti-freezing level, poor anti-cracking durability, etc., and achieves improved flexural strength and good waterproof performance Impermeability function, the effect of improving crack resistance and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

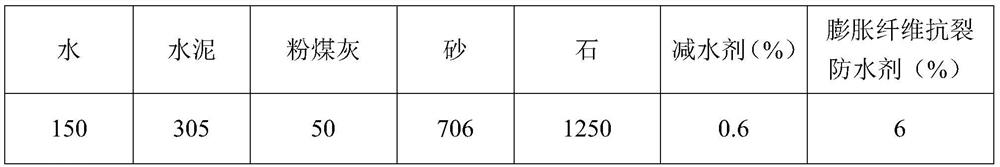

Method used

Image

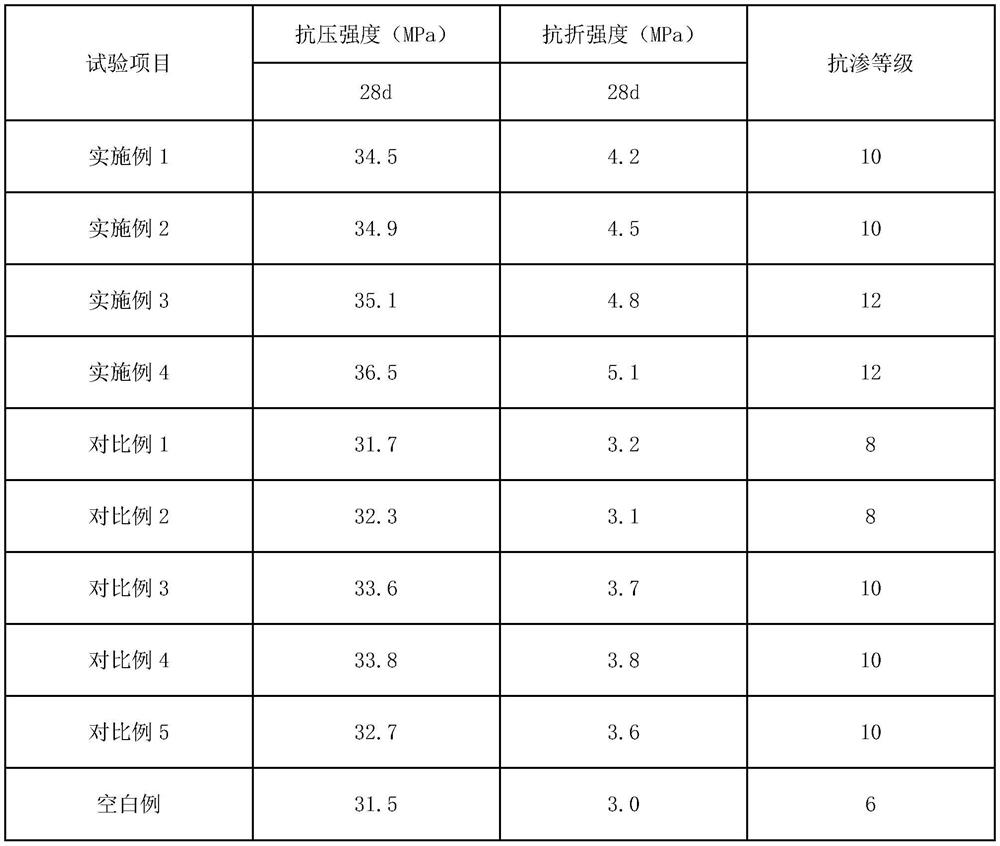

Examples

Embodiment 1

[0040] The expansion fiber anti-crack waterproof agent of this embodiment is composed of the following raw materials in mass percentage: 30% of anti-crack expansion agent, 20% of micropearl powder, 45% of coal gangue, 0.5% of modified basalt fiber, carboxymethyl cellulose Chitosan 2%, sodium sulfate 1.3%, water reducer 1.0%, defoamer 0.2%.

[0041] The preparation method of the modified basalt fiber is as follows:

[0042] (S1) first cleaning the basalt fiber with dilute hydrochloric acid with an HCl content of 10%;

[0043] (S2) Prepare a mixed solution of concentrated sulfuric acid and nitric acid with a mass ratio of 50:1, and place it in an ice bath to cool. When the mixed solution is lower than 5°C, add the cleaned basalt fiber, stir evenly, and react for 10 minutes;

[0044] (S3) adding HNO to the basalt fiber prepared in (S2) 3 For a mixed solution of nitric acid and hydrofluoric acid with a content of 30wt% and a HF content of 20%, the temperature is raised to 50°C, ...

Embodiment 2

[0049] The expansion fiber anti-crack waterproof agent of this embodiment is composed of the following raw materials in mass percentage: 10% of anti-crack expansion agent, 40% of micropearl powder, 42% of coal gangue, 5% of modified basalt fiber, carboxymethyl cellulose Chitosan 0.4%, Potassium Aluminum Sulfate 2%, Water Reducer 0.5%, Defoamer 0.1%.

[0050] The preparation method of the modified basalt fiber is as follows:

[0051] (S1) first cleaning the basalt fiber with dilute hydrochloric acid with an HCl content of 10%;

[0052] (S2) Prepare a mixed solution of concentrated sulfuric acid and nitric acid with a mass ratio of 40:1, and place it in an ice bath to cool. When the mixed solution is lower than 5°C, add the cleaned basalt fiber, stir evenly, and react for 10 minutes;

[0053] (S3) adding HNO to the basalt fiber prepared in (S2) 3 For a mixed solution of nitric acid and hydrofluoric acid with a content of 30wt% and a HF content of 20%, the temperature is raised...

Embodiment 3

[0058] The expansion fiber anti-crack waterproof agent of this embodiment is composed of the following raw materials in mass percentage: 20% of anti-crack expansion agent, 30% of micropearl powder, 42.9% of coal gangue, 3% of modified basalt fiber, carboxymethyl cellulose Chitosan 1.5%, calcium formate 1.6%, calcium nitrate 0.4%, water reducer 0.5%, defoamer 0.1%.

[0059] The preparation method of the modified basalt fiber is as follows:

[0060] (S1) first cleaning the basalt fiber with dilute hydrochloric acid with an HCl content of 10%;

[0061] (S2) Prepare a mixed solution of concentrated sulfuric acid and nitric acid with a mass ratio of 45:1, and place it in an ice bath to cool. When the mixed solution is lower than 5°C, add the cleaned basalt fiber, stir evenly, and react for 10 minutes;

[0062] (S3) adding HNO to the basalt fiber prepared in (S2) 3 For a mixed solution of nitric acid and hydrofluoric acid with a content of 30wt% and a HF content of 20%, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com