Hot galvanizing hanging tool

A hot-dip galvanizing and hanger technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as uneven distribution of hanging parts, iron wire, labor waste, poor galvanizing quality, etc. , to achieve the effect of simple and convenient unloading, good galvanizing effect and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

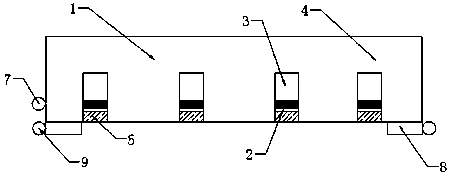

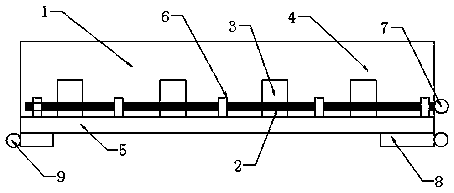

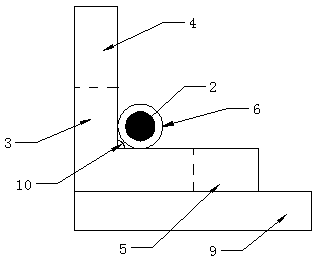

[0020] Such as Figure 1-3 As shown: this embodiment is a hot-dip galvanized hanger, including a hanger body 1 and a hanger pin 2, the middle part of the hanger body 1 is formed with four rectangular holes 3 equidistantly spaced, and four The rectangular holes 3 arranged at equidistant intervals are all parallel to the longitudinal axis of the hanger body 1, and the hanger body 1 forms a bending structure along the central transverse axis, and the bending structure divides the hanger body 1 into a vertical section 4 and a horizontal section 4. section 5, and the angle between the vertical section 4 and the horizontal section 5 is 90 degrees, five snap rings 6 are arranged on the upper side of the horizontal section 5 close to the vertical section 4, and the five snap rings 6 are respectively located in the adjacent Between the two rectangular holes 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com