Platform construction system

A platform and cover plate technology, which is applied in the field of performance, advertising structure construction, and exhibition display. It can solve the problems of complex decorative parts and installation process, long time-consuming disassembly and assembly, and large cumulative error, so as to achieve convenient and fast connection and disassembly. Save manpower, material and financial resources, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

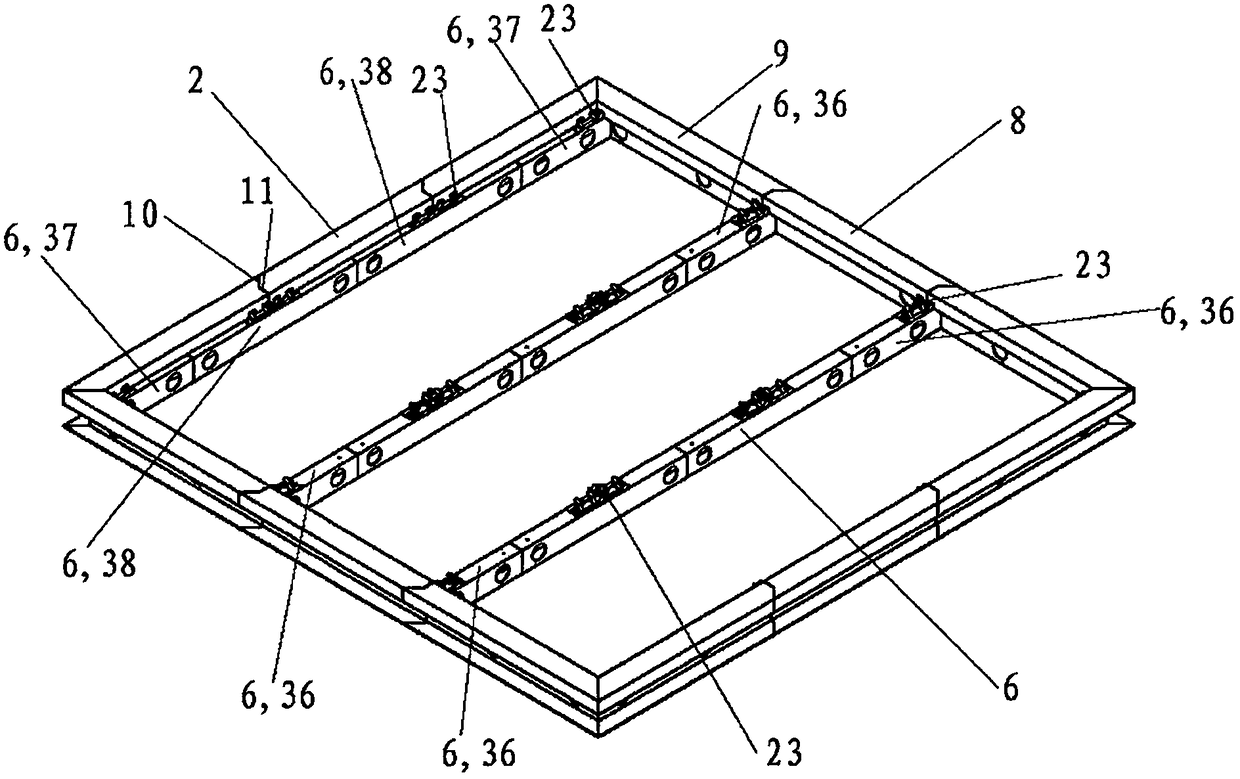

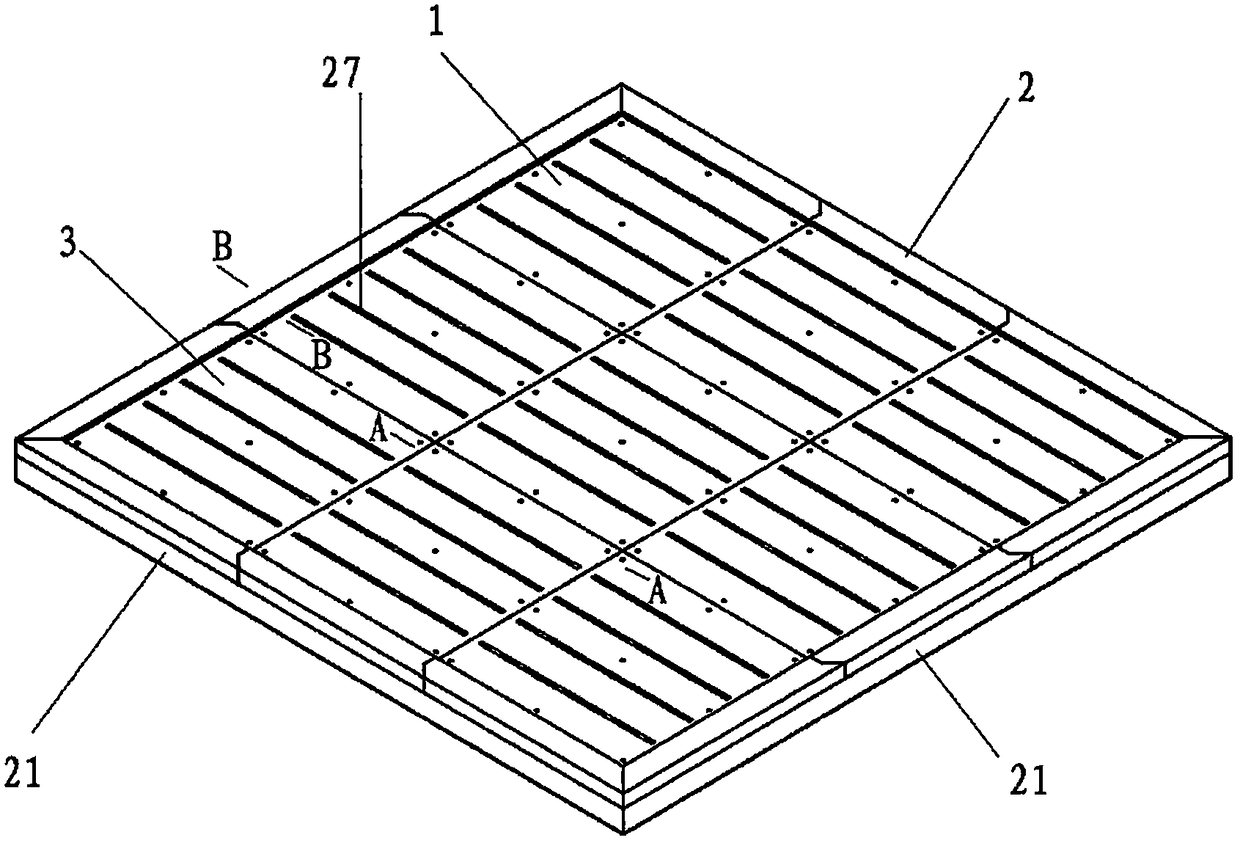

[0047] refer to Figure 1-5 , 8-10, a platform construction system, including keel, cover plate 1, edge trim strip 2, the cover plate includes a square horizontal main board body 3 and four vertical side panels 4, the side panels The board and the main body are integrally structured, the length of the side plates is equal to the side length of the main body, and a decorative panel 5 is installed on the main body.

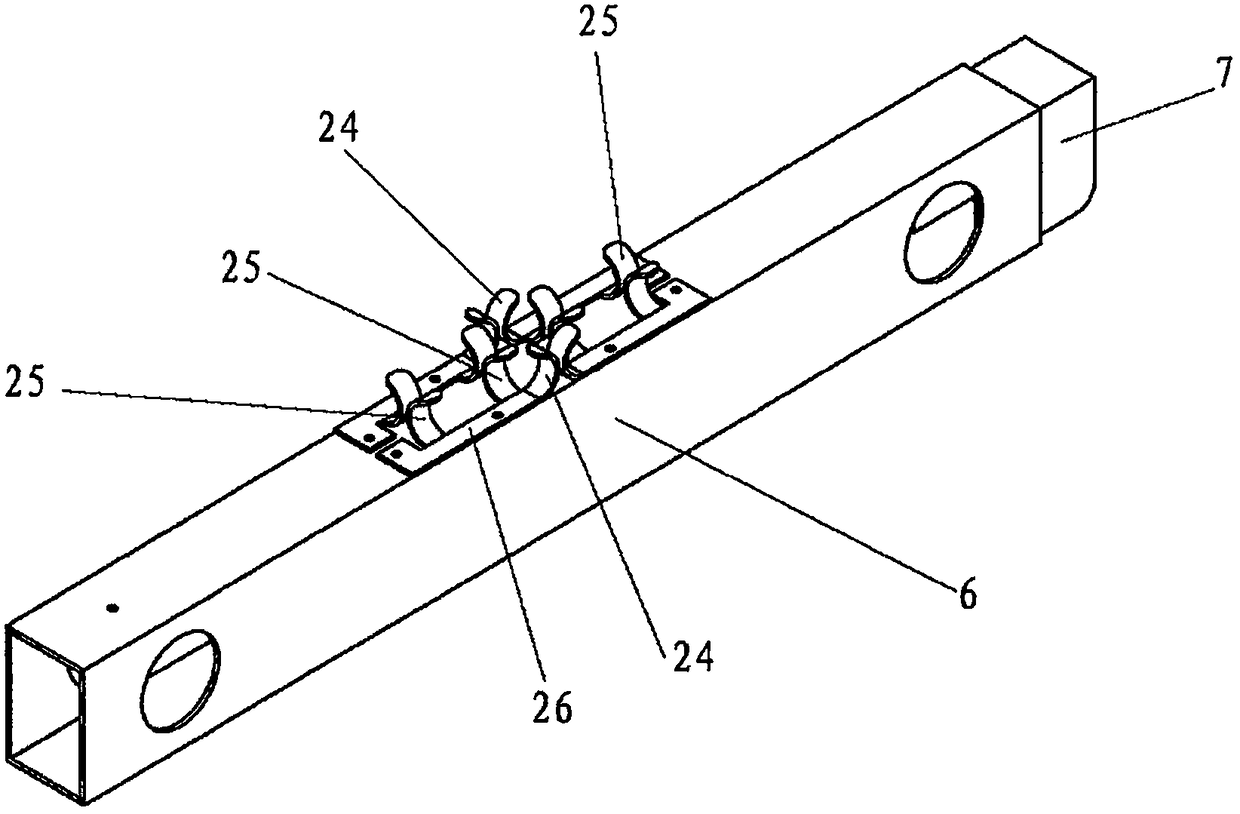

[0048] The keel includes a plurality of keel parts parallel to each other, and each keel part is connected by a plurality of keel profiles 6 through keel connectors 7. The keel profiles are rectangular pipes, and the keel connectors are fixedly inserted at one end of the keel profiles. And the cross-section is an inverted U-shaped profile, the keel connector partially protrudes from the one end of the keel profile, and the cross-sectional size of the keel connector is such that it can be inserted into the keel profile.

[0049] The edge-receiving edge strips includ...

Embodiment 2

[0053] refer to figure 2 , 4 . As shown in 6-10, a platform construction system includes a keel, a cover plate 1, and edge strips 2. The cover plate includes a square horizontal main board body 3 and four vertical side plates 4. The side plates The board and the main body are integrally structured, the length of the side plates is equal to the side length of the main body, and a decorative panel 5 is installed on the main body.

[0054] The keel includes a plurality of keel parts parallel to each other, and each keel part is connected by a plurality of keel profiles 6 through keel connectors 7. The keel profiles are rectangular pipes, and the keel connectors are fixedly inserted at one end of the keel profiles. And the cross-section is an inverted U-shaped profile, the keel connector partially protrudes from the one end of the keel profile, and the cross-sectional size of the keel connector is such that it can be inserted into the keel profile.

[0055] The edge-receiving e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com