Chopping preventive shield

A shield and anti-cutting technology, which is applied in the direction of defensive objects, can solve the problems of insufficient ability, throwing liquid splash, damage, etc., and achieve the effects of avoiding damage, improving safety, and good attack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

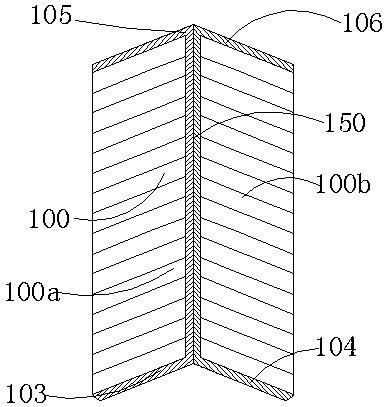

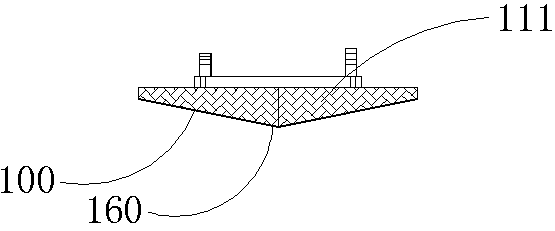

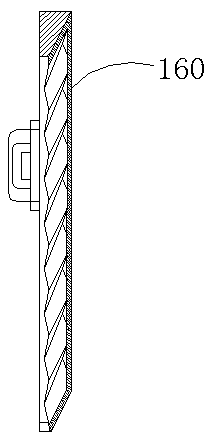

[0040] Embodiment 1: as Figure 1-5As shown, an anti-slash shield includes a shield body 1, a handle 4, a pad 2 and an elbow locking fixture 3. The shield body 1 includes a shield body front 100, a shield body back 140, and a shield head 110. and the shield tail 120, the shield body front 100 extends from the shield head 110 to the shield tail 120, the pad 2 is connected to the shield body back 140, the handle 4 and the elbow locking fixture 3 Pass through the pad 2 and connect with the shield body 1. The shield body front 100 is provided with an outer convex surface and a shield ridge 150. When the outer convex surface extends from the front left and right sides of the shield body to the middle, its height gradually increases and intersects with the shield ridge 150, the shield ridge 150 is higher than the outer convex surface, and the shield ridge 150 is covered with an anti-cut strip 160. The height described in this embodiment is the vertical distance from any position on ...

Embodiment 2

[0049] Example 2, such as Figure 7 As shown, an embodiment improved on the basis of Example 1 mainly changes the shape of the shield guide groove from V-shape to U-shape. Specifically, the front of the shield body is provided with a left guide groove group 100a and a right guide groove group 100b, the left guide groove group 100a is composed of a plurality of left guide grooves 101, and the right guide groove group 100b It consists of a plurality of right guide grooves 102, the left guide groove 101 extends from the left edge of the shield body front 100 along the inclined upward direction of the outer convex surface, and the right guide groove 102 extends from the shield body front right edge Extending obliquely upward along the surface of the outer convex surface, the left guide groove 101 and the right guide groove 102 form an inclined downward guide groove viewed from the shield head to the shield tail, and the left guide groove 101 includes a groove Top edge 101h, groov...

Embodiment 3

[0051] Example 3 as Figure 9 As shown, an embodiment improved on the basis of Example 1 mainly changes the shield ridge 150 from a V-shaped plane to a V-like arc surface with wavy folds. The anti-slashing strip 160 is also arranged as a wave-shaped wrinkled surface, which is connected by known techniques such as bonding, riveting, snap-fitting, etc. This wave-shaped wrinkled surface can prevent horizontal or oblique cutting The knife that hits directly slides out of the shield, so that the knife slides on the wavy folded surface of the anti-cut strip of the shield in a wavy curve, which increases the sliding distance and sliding resistance. Both the crest and the trough position of the wrinkled surface can be set, or only the crest or trough position can be set, which not only helps to alleviate the impact force, but also helps to disarm.

[0052] To sum up, this kind of shield is effective for resisting slashing and protecting the shield from being damaged when being attacked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com