Fault feature extraction method of automobile hub bearing based on optimal quality factor selection

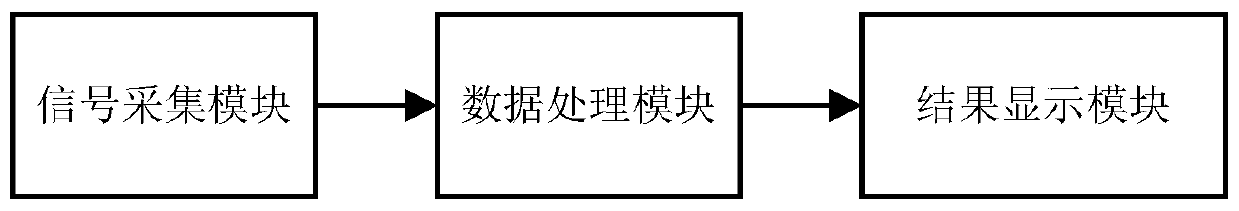

A technology for automobile hubs and fault characteristics, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., and can solve the problem of large random selection of quality factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] First, select the automobile hub bearing shown in Table 1. Then, cut a groove with a width of 0.3mm and a depth of 0.05mm on the outer ring of the bearing. Finally, install the acceleration sensor on the bearing seat to obtain the vibration signal x in the vertical direction.

[0078] Table 1 Parameters of hub bearings

[0079]

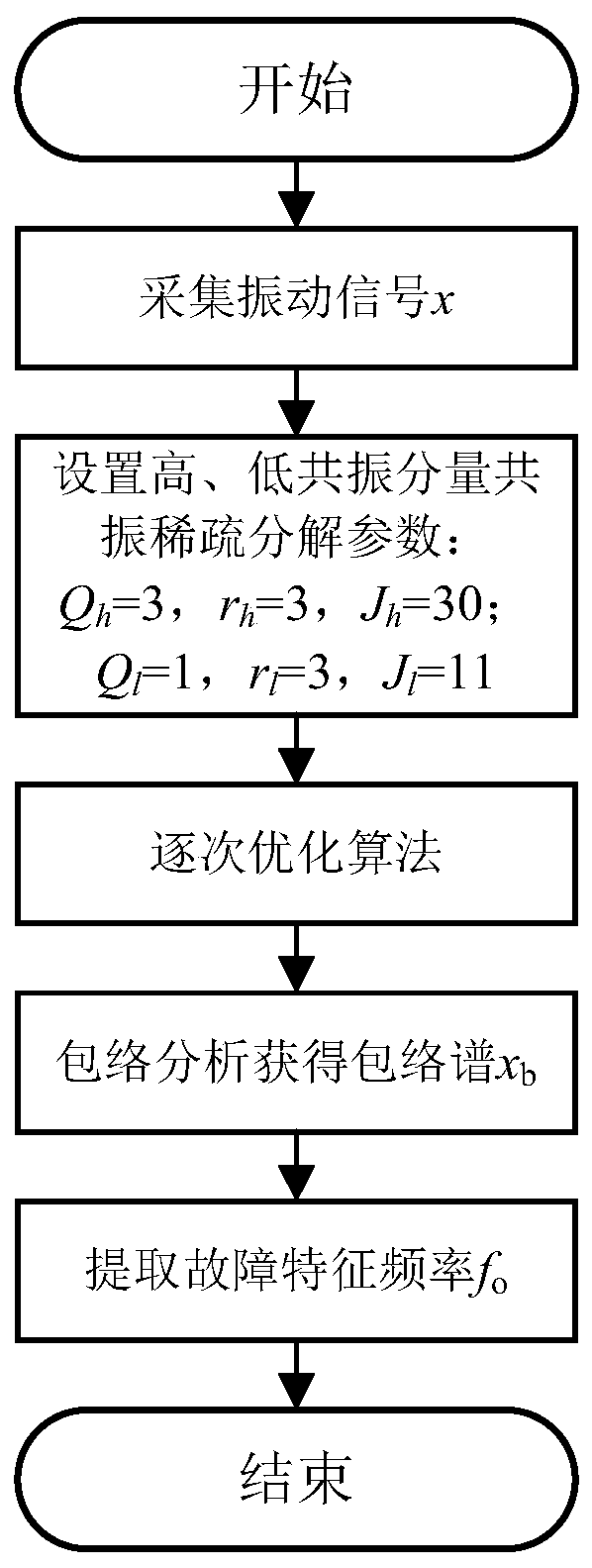

[0080] Step 1: The information collection module collects the vibration signal x of the automobile hub bearing through the acceleration sensor, and its waveform is as follows: Figure 4 shown. Sampling frequency f s It is 100kHz, the sampling time t is 0.5s, and the number of sampling points N is 50000.

[0081] Step 2: The resonance sparse decomposition parameter initialization module sets the initial resonance sparse decomposition parameter Q h = 3, r h = 3,J h =30;Q l = 1, r l = 3,J l =11.

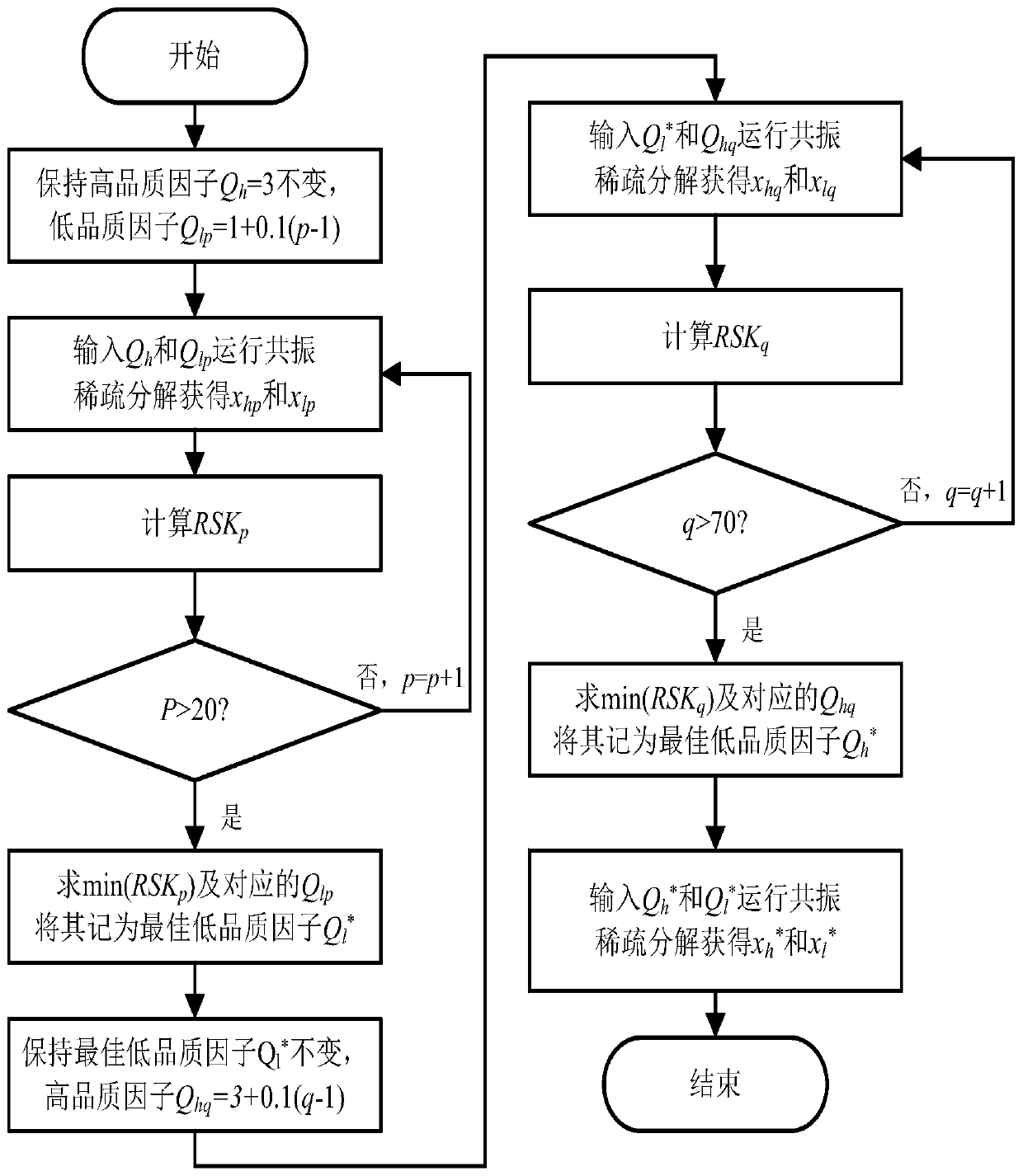

[0082] Step 3: The quality factor is optimized successively for high and low quality factors Q h and Q l Perform optimization to find th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com