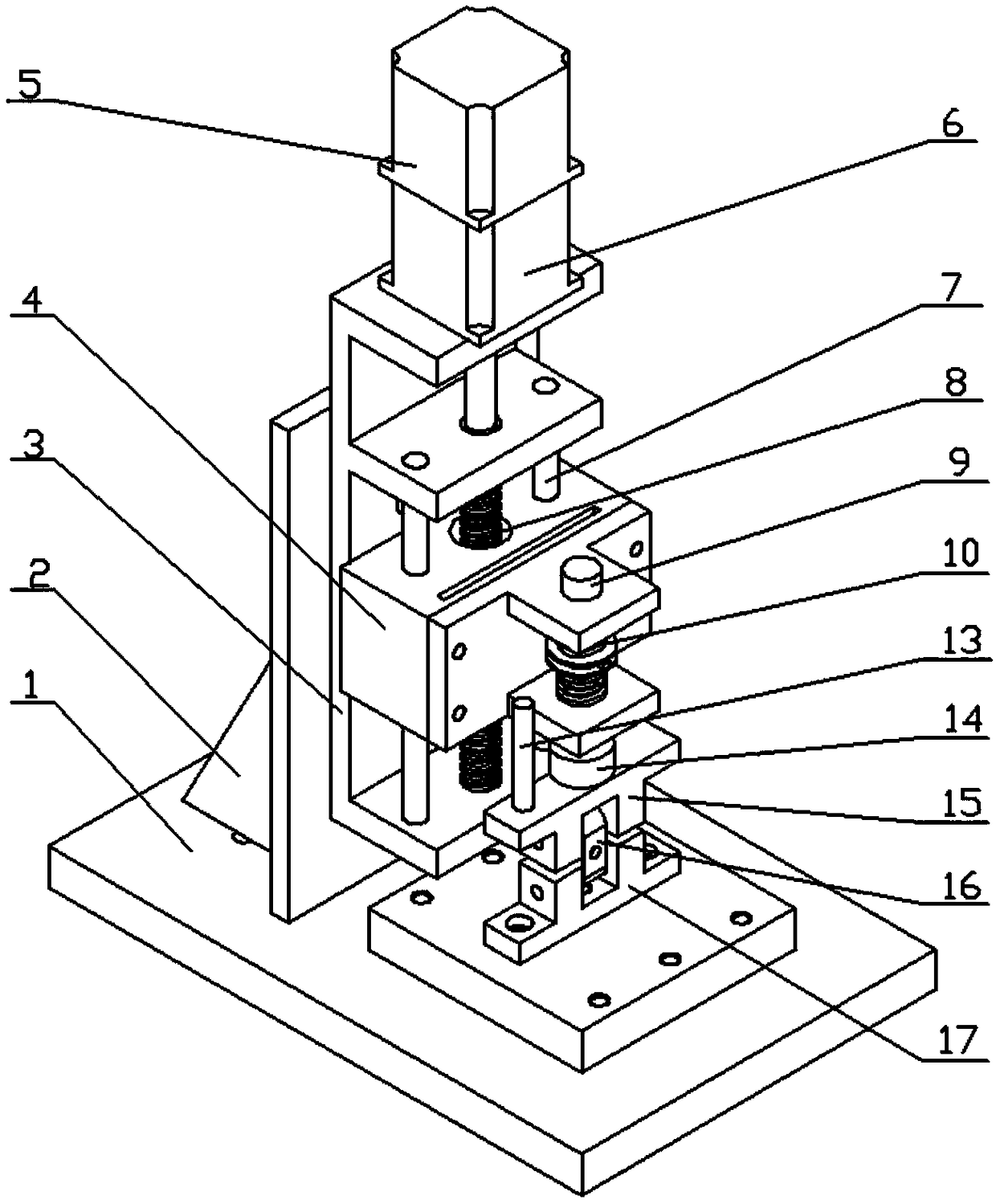

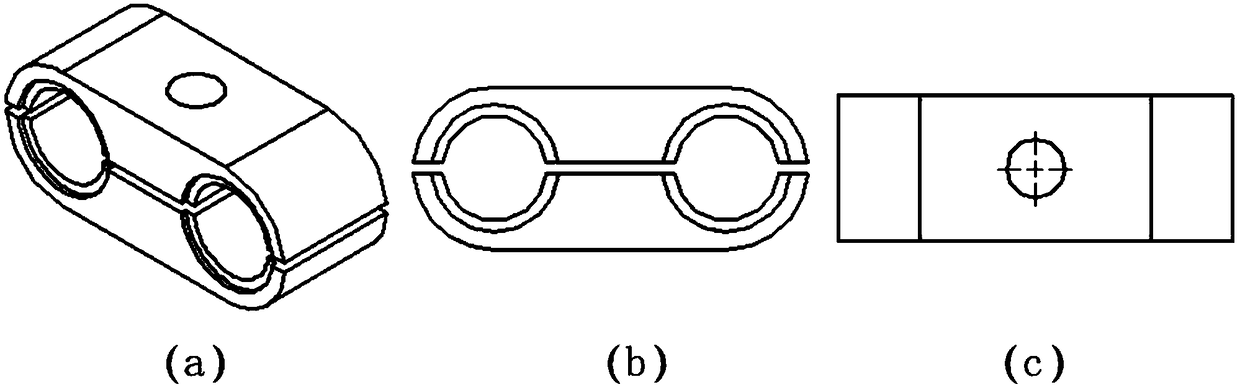

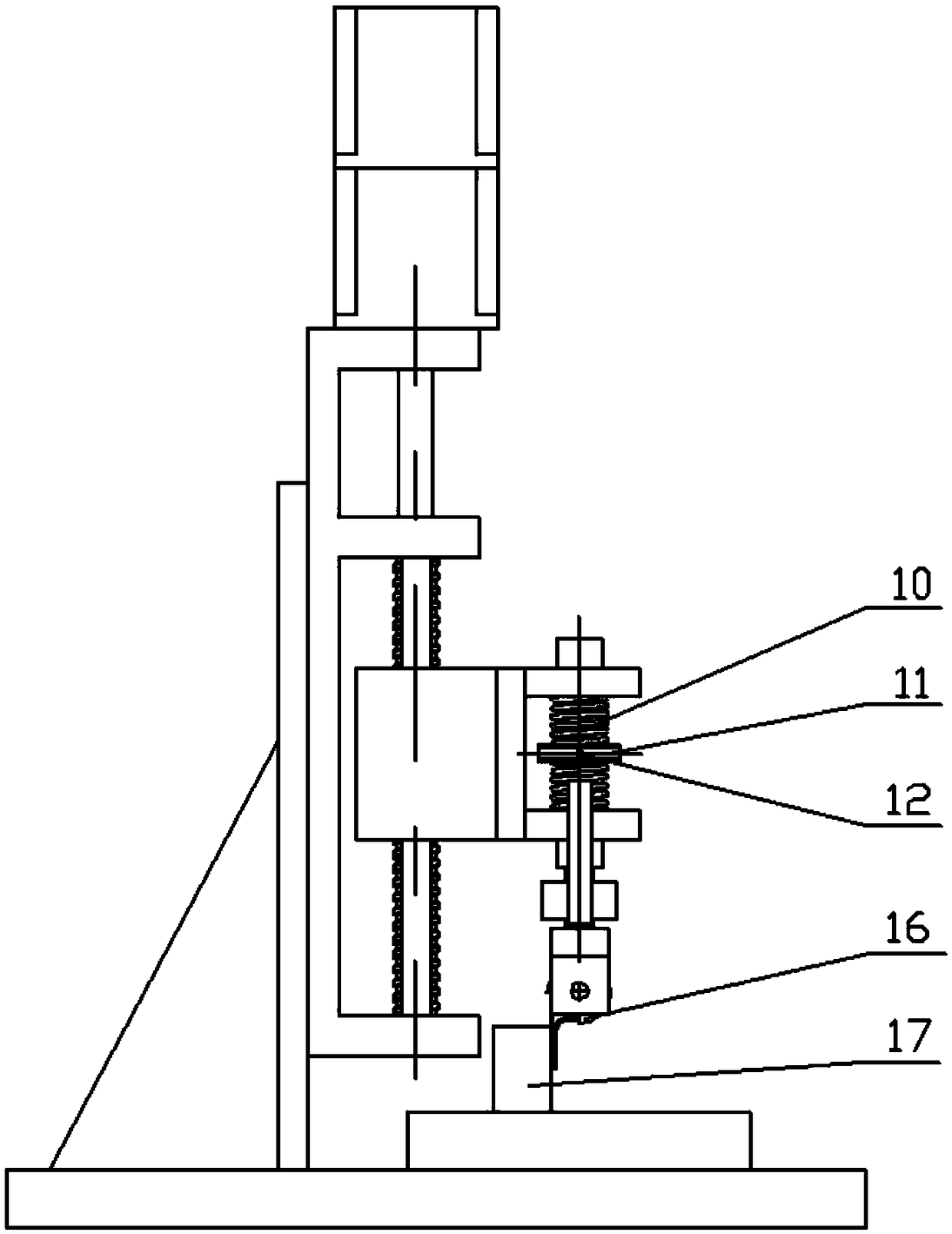

Device for automatically calibrating clamp rigidity and application method thereof

An automatic calibration and stiffness technology, applied in the mechanical field, can solve the problems affecting the calibration accuracy of clamps, the force-displacement curve is not smooth enough, the loading force and displacement fluctuations, etc., and achieve the effect of smooth and continuous stiffness test process and accurate stiffness measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the present invention, the orientation or positional relationship indicated by terms such as "upper", "lower", "left", "right", "front", "rear", "vertical", "horizontal" etc. are based on the drawings The orientation or positional relationship shown is just a relative term determined for the convenience of describing the structural relationship of the various components or elements of the present invention, and does not specifically refer to any component or element in the present invention, and should not be construed as a limitation of the present invention.

[0026] In the present invention, terms such as "connected" and "connected" should be understood in a broad sense, indicating that they can be fixedly connected, integrally connected or detachably connected; they can be directly connected or indirectly connected through an intermediary. For relevant researchers or technical personnel in the field, the specific meanings of the above terms in the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com