An upper lamp box of a macroscopic inspection machine

A macro inspection and light box technology, applied in optics, instruments, photography, etc., can solve the problems of waiting time, lighting time, long lighting and extinguishing interval, low macro detection efficiency, etc., and achieve real-time use, real-time switching, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

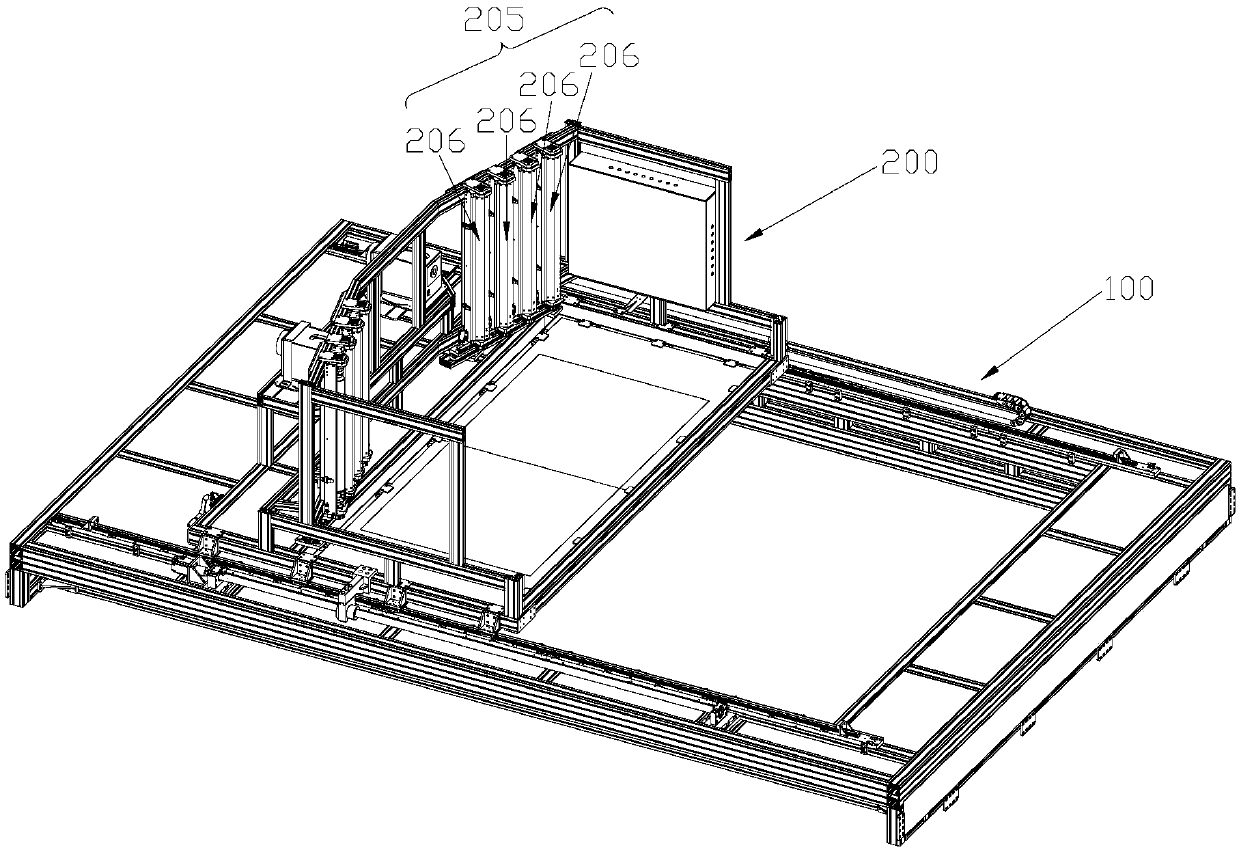

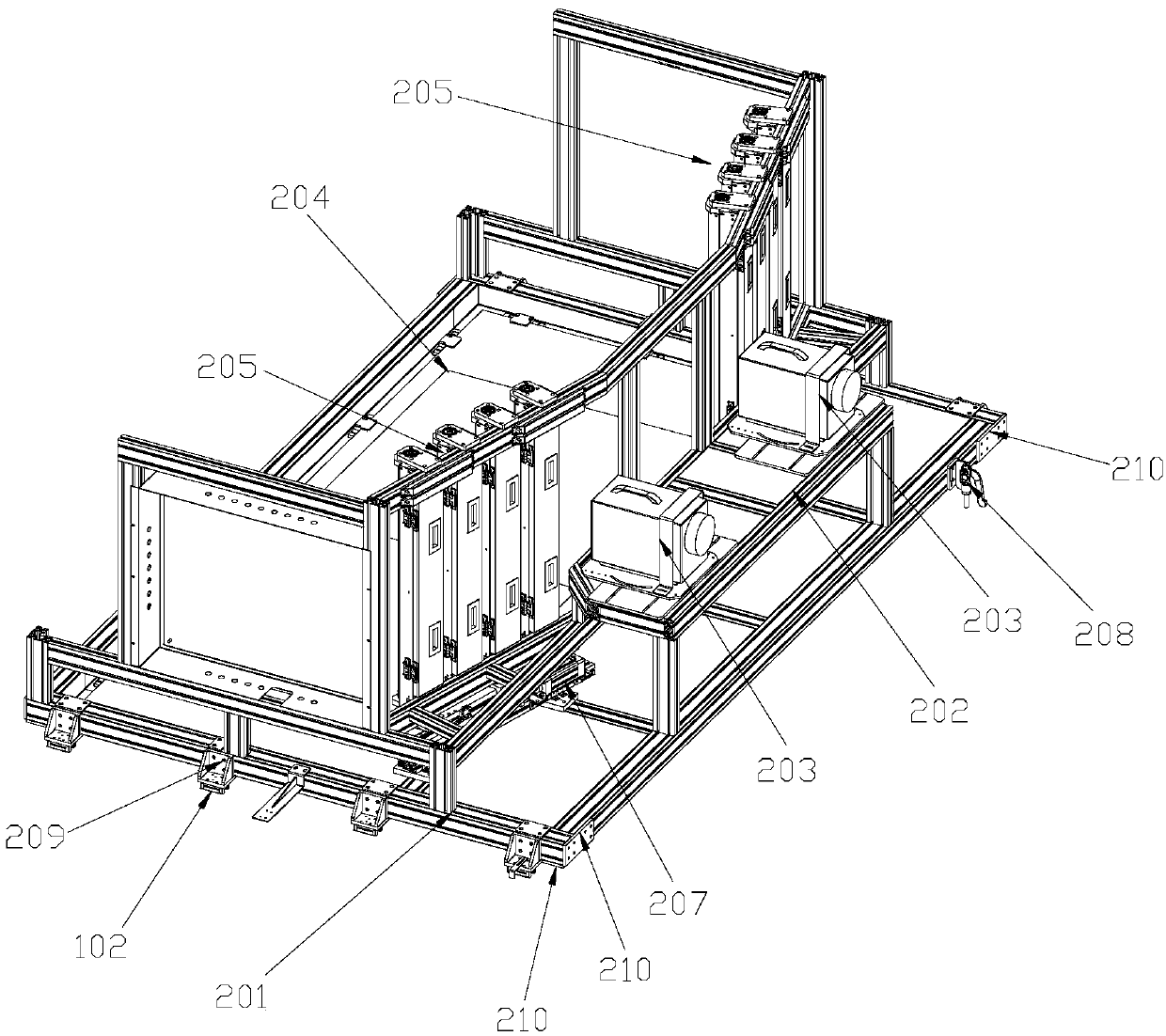

[0030] Such as figure 1 As shown, the upper light box of the macro inspection machine of the present invention includes a light box seat 100 and a light box main body 200 .

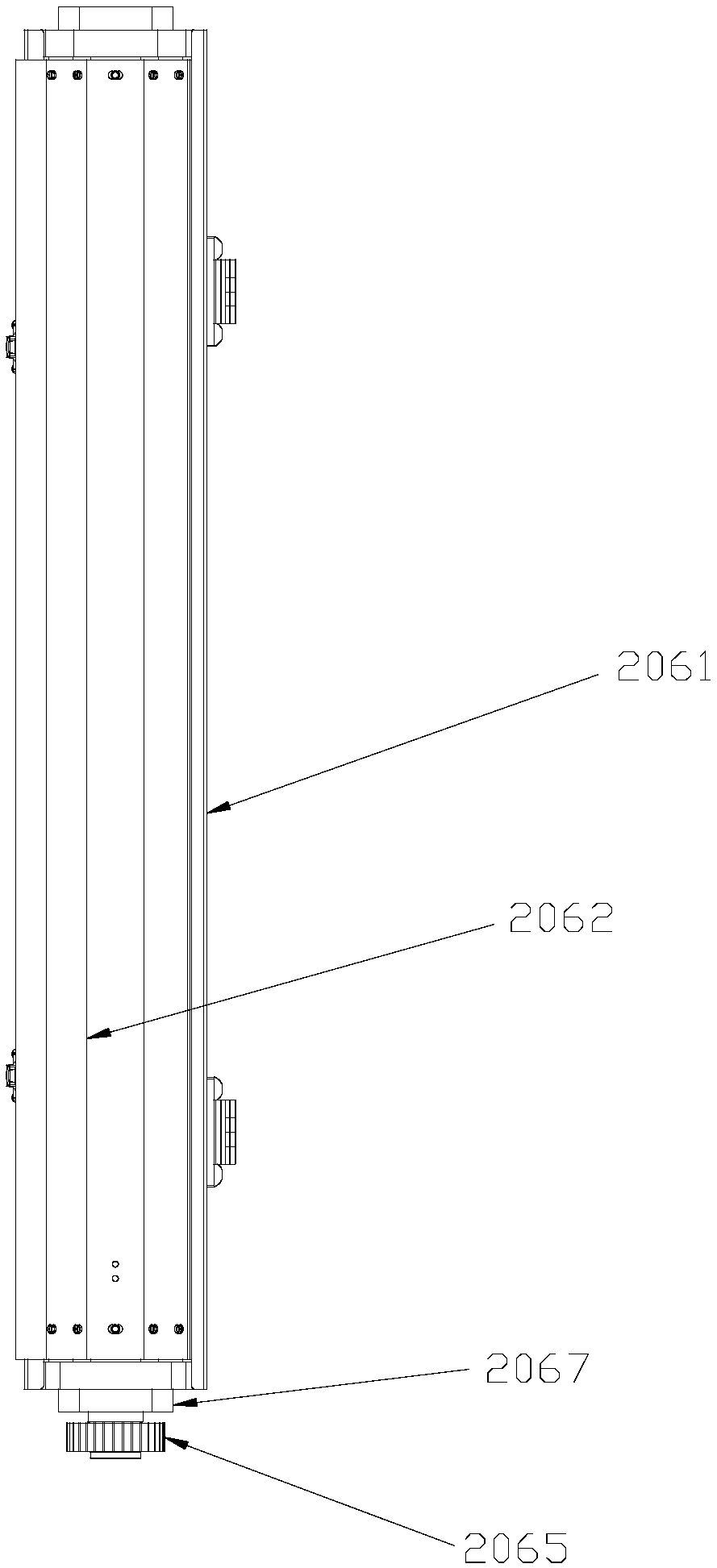

[0031] Such as Figure 1 to Figure 4 As shown, the light box main body 200 includes a moving frame 201 , a metal lamp assembly, a sodium lamp group 205 and a driving mechanism 207 . Wherein, the moving frame 201 is slidably connected with the light box base 100; the metal lamp assembly includes a metal lamp fixing seat 202 fixed on the moving frame 201, a metal lamp 203 installed on the metal lamp fixing seat 202, and is arranged on the moving frame 201 and located The optical glass 204 at the focal point of the light of the metal lamp 203, the optical glass 204 is used for the convergence or diffusion of the lamp tube of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com