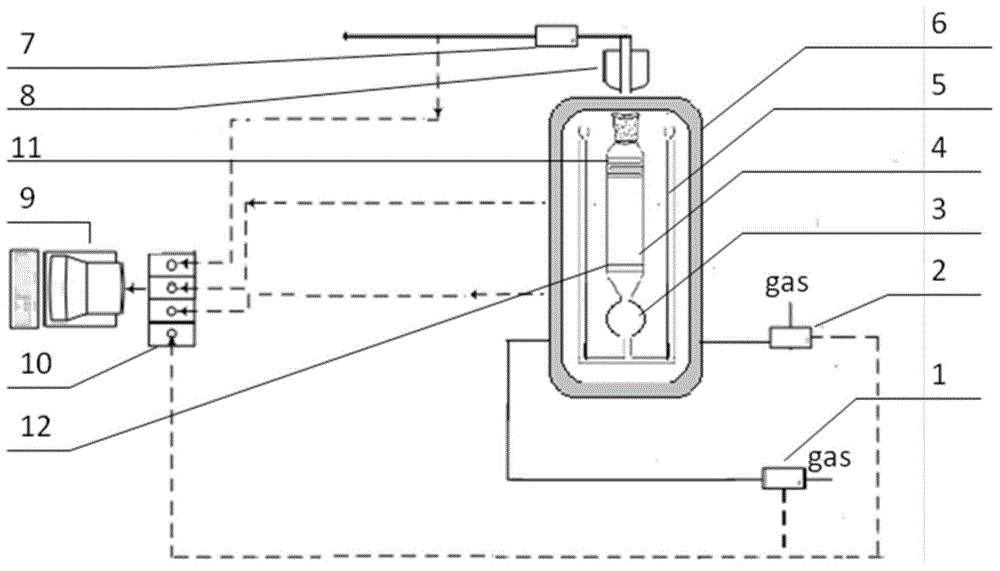

Isothermal differential reaction analyzer of mini-type gas-phase, liquid-phase and solid-phase slurry reactor

A differential reaction and micro-reactor technology, applied in analytical materials, chemical method analysis, instruments, etc., can solve the problems of difficulty in measuring reaction kinetic parameters of fast reactions, low reaction temperature, etc., and achieve mass transfer performance, fast, efficient, and economical. Space, the effect of preventing particle overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Implementation example 1: Methyl methacrylate preparation experiment, feed nitrogen, take 25mL methanol and methacrolein mixed reaction solution, add 5% solid catalyst, when the temperature reaches 80°C and the pressure is 0.3Mpa, control and switch to feed oxygen , the gas flow rate is 200mL / min, and the test is carried out to obtain the in-situ infrared data of the concentration change of the functional group ester bond with time, which is increasing continuously, and the reaction rate at this temperature is confirmed, and the reaction kinetic model is further calculated according to the Arrhenus equation is = 0.792e 0.637t .

Embodiment 2

[0032]Implementation example 2: 2-methyl-2,4-pentanediol preparation experiment, pass nitrogen, take 25mL diacetone alcohol reaction liquid, add 5% nickel solid catalyst, when the temperature reaches 120 ° C, when the pressure is 1.5Mpa, control Switch to hydrogen gas, the gas flow rate is 200mL / min, and conduct a test to obtain the concentration change of the functional group ketone bond with time in the in-situ infrared data, which is continuously decreasing, and confirm the reaction speed at this temperature, and further calculate according to the Arrhenus equation The reaction kinetic model is = 0.458e -0.326t .

Embodiment 3

[0033] Implementation example 3: Terephthalic acid preparation experiment, blowing nitrogen gas, taking 25mL of p-xylene and acetic acid mixed reaction solution, adding 5% Co-Mn-Br solid catalyst, when the temperature reaches 200 °C and the pressure is 1.2Mpa, control switching Oxygen is introduced, the gas flow rate is 200mL / min, and the test is carried out to obtain the concentration change of the acid bond of the functional group with time in the in-situ infrared data, which is continuously increasing, and the reaction speed at this temperature is confirmed, and the reaction is further calculated according to the Arrhenus equation The kinetic model is = 0.0242e -6.8 / t .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com