A battery liquid injection vibrating device

A vibrating device and liquid injection technology, which is applied in the direction of battery pack components, circuits, electrical components, etc., can solve the problems of low liquid injection efficiency and long battery cell injection time, shorten the liquid injection time, and prevent fixed Steady or leaky, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

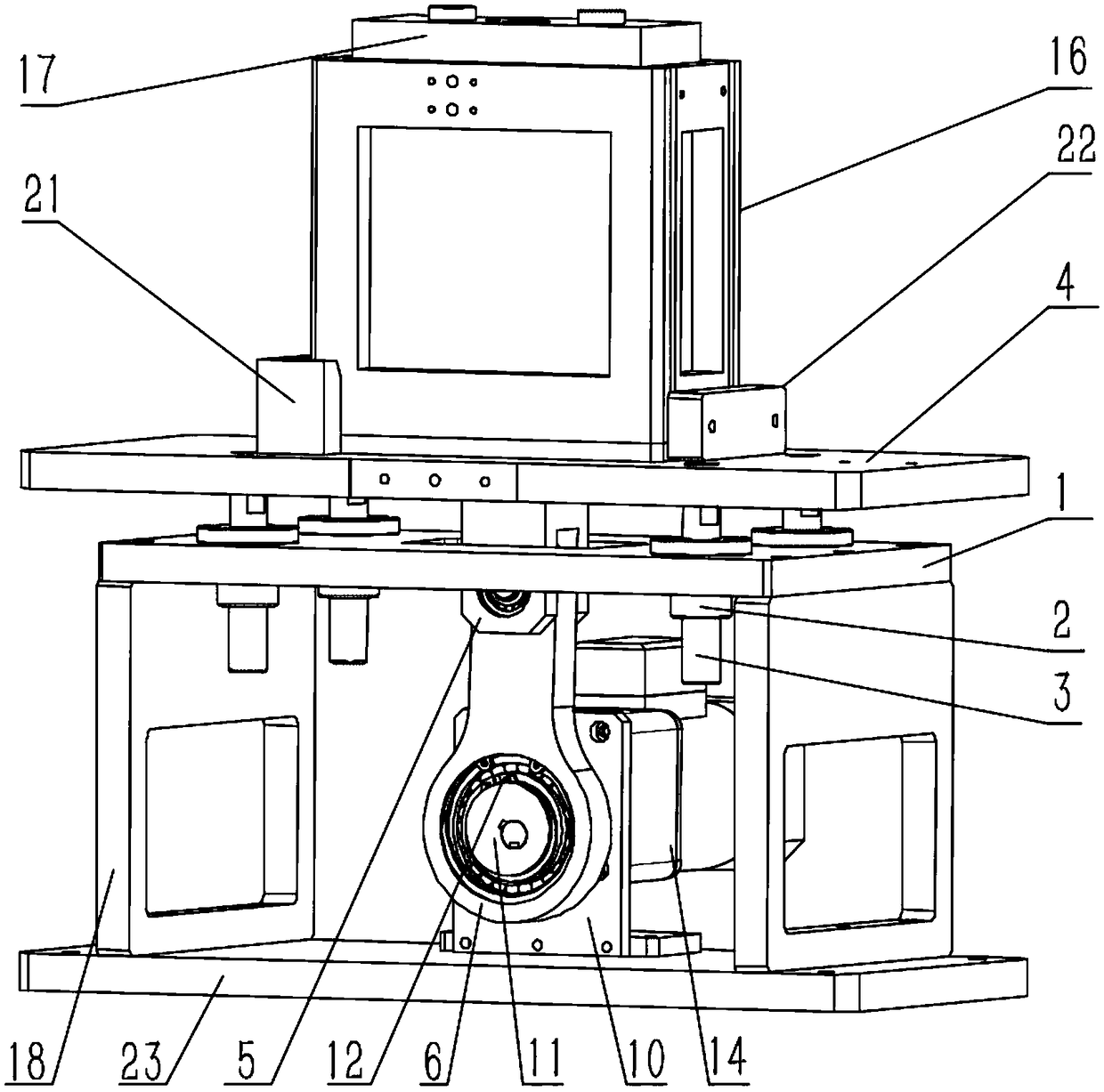

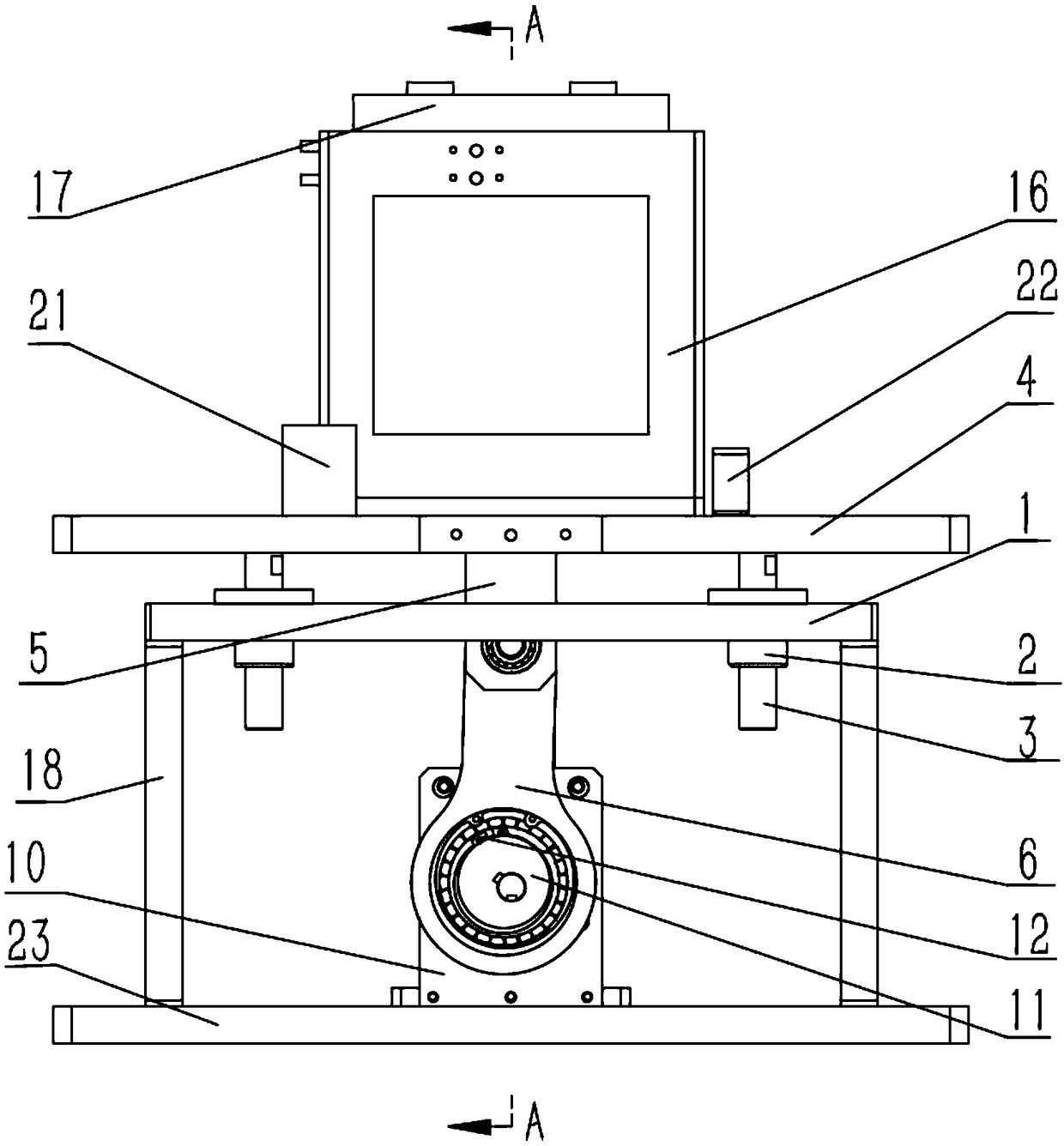

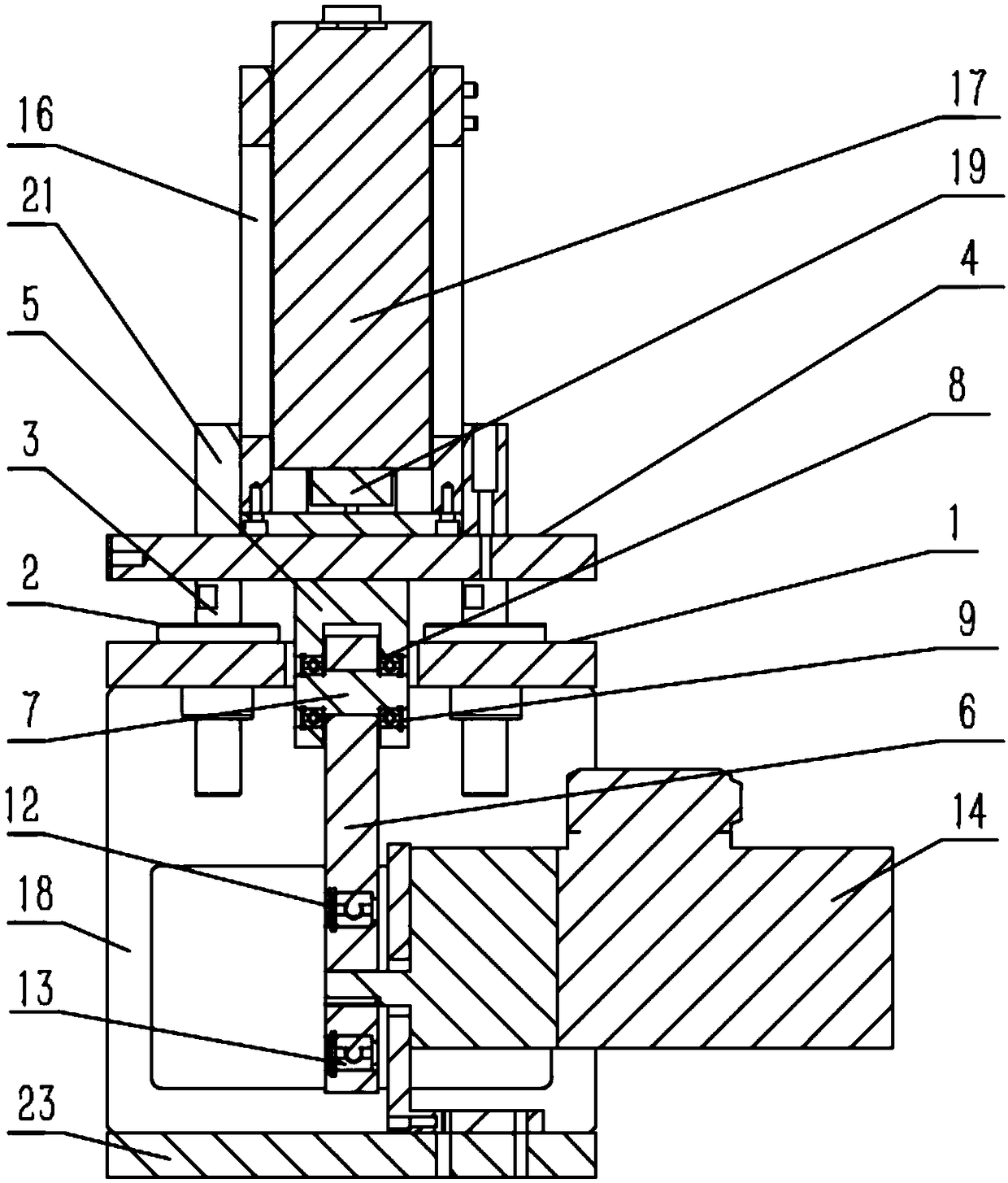

[0024] Such as figure 1 and figure 2 As shown, the battery liquid injection vibration device of this embodiment includes a horizontally installed bottom plate 23, two vertical plates 18 are installed at intervals above the bottom plate 23, and a fixed plate 1 parallel to the bottom plate 23 is installed on the top of the vertical plate 18 to fix A plurality of through holes are opened on the plate 1, and a guide post 3 is installed in the through hole through a linear bearing device 2, the guide post 3 passes through the upper and lower ends of the entire fixed plate 1, and a floating plate 4 is supported on the top of the guide post 3, floating A jig 16 is installed on the upper surface of the plate 4, and a cell 17 injected with heated electrolyte is fixed inside the jig 16 (heating temperature < 60°C); A motor 14 is fixed, an eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com