A kind of preparation method of ibuprofen colon-targeted slow-release microspheres

A slow-release microsphere and colon-targeting technology, which is applied to non-active ingredient medical preparations, active ingredient-containing medical preparations, microcapsules, etc., can solve the problem that the microsphere structure is not dense enough and colon-targeted drug delivery is not possible and other issues, to achieve good biocompatibility and degradability, improve drug efficacy, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

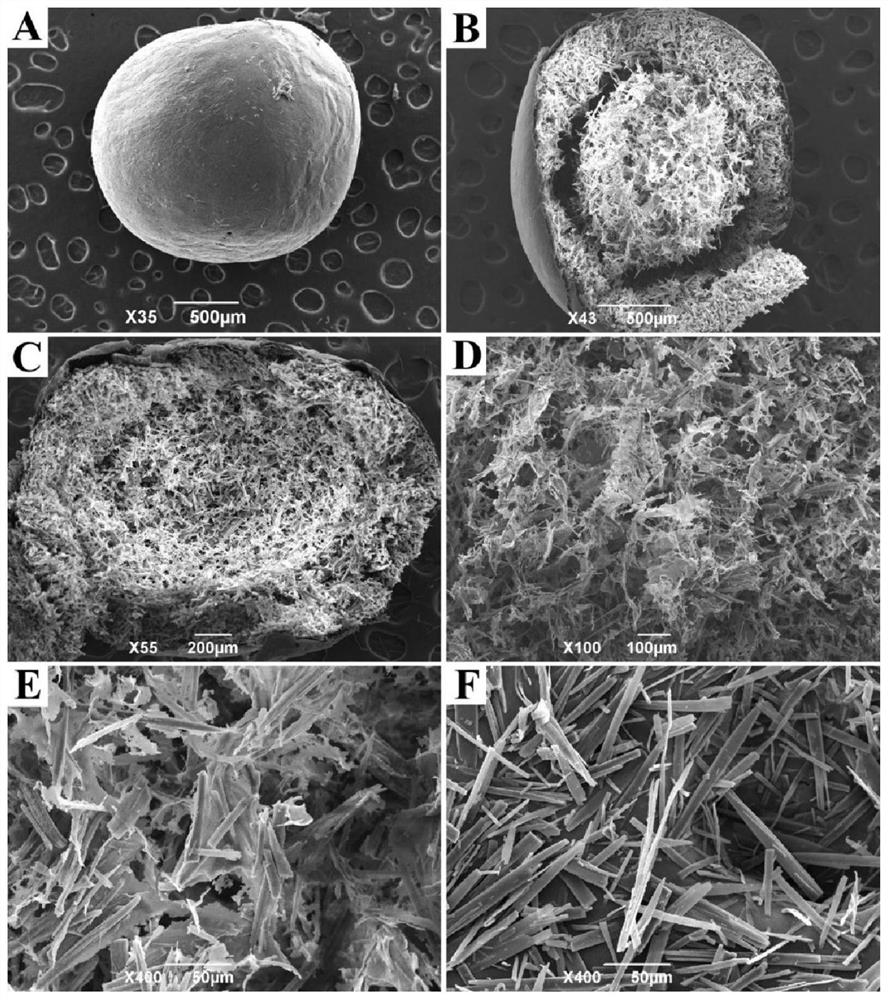

[0031] The preparation method of ibuprofen colon-targeted slow-release microspheres, the steps are as follows:

[0032] (1) Dissolve chitosan in 1% (v / v) acetic acid solution, adjust pH to 3.5, then add ibuprofen, vortex and ultrasonic, disperse evenly, prepare chitosan concentration as 30mg / mL, The ibuprofen concentration was 50 mg / mL in the inner mixed phase.

[0033] (2) Dissolve carboxymethyl konjac glucomannan and sodium tripolyphosphate in water to prepare an external mixture with carboxymethyl konjac glucomannan concentration of 7.5 mg / mL and sodium tripolyphosphate concentration of 2.5 mg / mL Mutually.

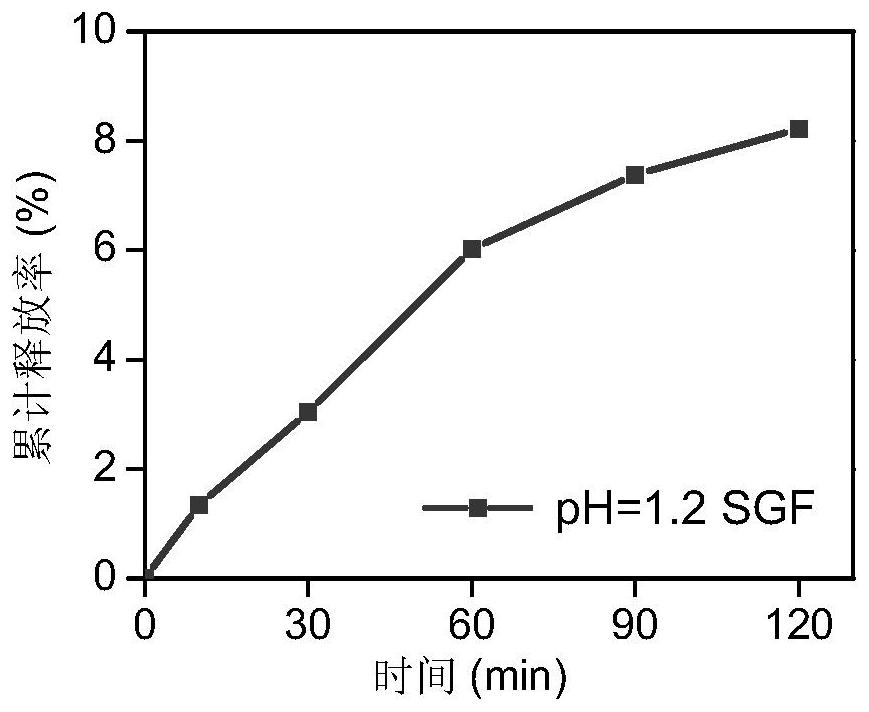

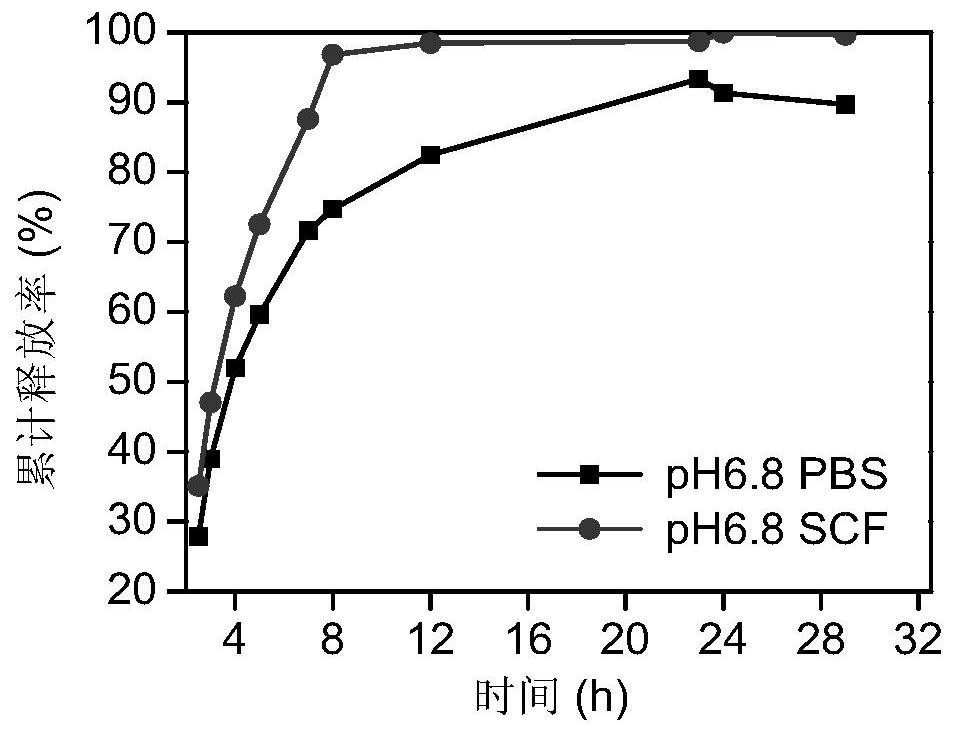

[0034] (3) Under magnetic stirring (500-600r / min), add the inner water phase to the outer water phase drop by drop with a syringe, the volume ratio of the inner mixed phase to the outer mixed phase is 1:10, continue to stir and solidify for 15 minutes, The precipitate was washed three times with deionized water, and then freeze-dried for 2 hours to obtain ibuprofen dr...

Embodiment 2

[0041] (1) Dissolve chitosan in an acetic acid solution with a pH of 4.5, then add ibuprofen, vortex and ultrasonically disperse evenly, and prepare chitosan with a concentration of 20 mg / mL and ibuprofen with a concentration of 75 mg / mL internal mixed phase.

[0042] (2) Sodium alginate and sodium tripolyphosphate were dissolved in water respectively to prepare an external mixed phase with a sodium alginate concentration of 12.5 mg / mL and a sodium tripolyphosphate concentration of 5 mg / mL.

[0043] (3) Under magnetic stirring, use a syringe to add the inner water phase to the outer water phase drop by drop, the volume ratio of the inner mixed phase to the outer mixed phase is 1:8, continue to stir and solidify for 30 minutes, and then use deionized water to dissolve the precipitate Washed three times, and then freeze-dried for 3 hours to obtain ibuprofen drug-loaded microspheres.

[0044] The drug encapsulation efficiency of the drug-loaded microspheres was 64.24%, and the d...

Embodiment 3

[0048] (1) Dissolve chitosan in an acetic acid solution with a pH of 5.5, then add ibuprofen, vortex and ultrasonically disperse evenly, and prepare chitosan with a concentration of 45 mg / mL and ibuprofen with a concentration of 125 mg / mL internal mixed phase.

[0049] (2) Dissolving chondroitin sulfate and sodium tripolyphosphate in water respectively to prepare an external mixed phase with a concentration of chondroitin sulfate of 5 mg / mL and a concentration of sodium tripolyphosphate of 10 mg / mL.

[0050] (3) Under magnetic stirring, use a syringe to add the inner mixed phase to the outer mixed phase drop by drop, the volume ratio of the inner mixed phase to the outer mixed phase is 1:20, continue to stir and solidify for 15 minutes, and then use deionized water to dissolve the precipitate Washed 3 times, and then freeze-dried for 2 hours to obtain ibuprofen drug-loaded microspheres.

[0051] The drug encapsulation efficiency of the drug-loaded microspheres was 53.12%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com