Load-bearing inflatable radial tire

A technology for radial tires and tire circumference, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., which can solve the problems of tire durability, partial wear resistance, and handling stability that cannot be well balanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

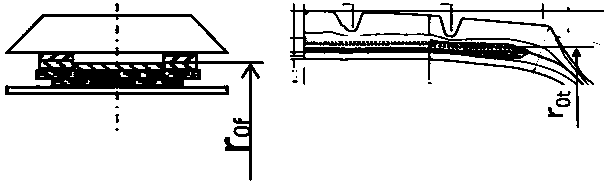

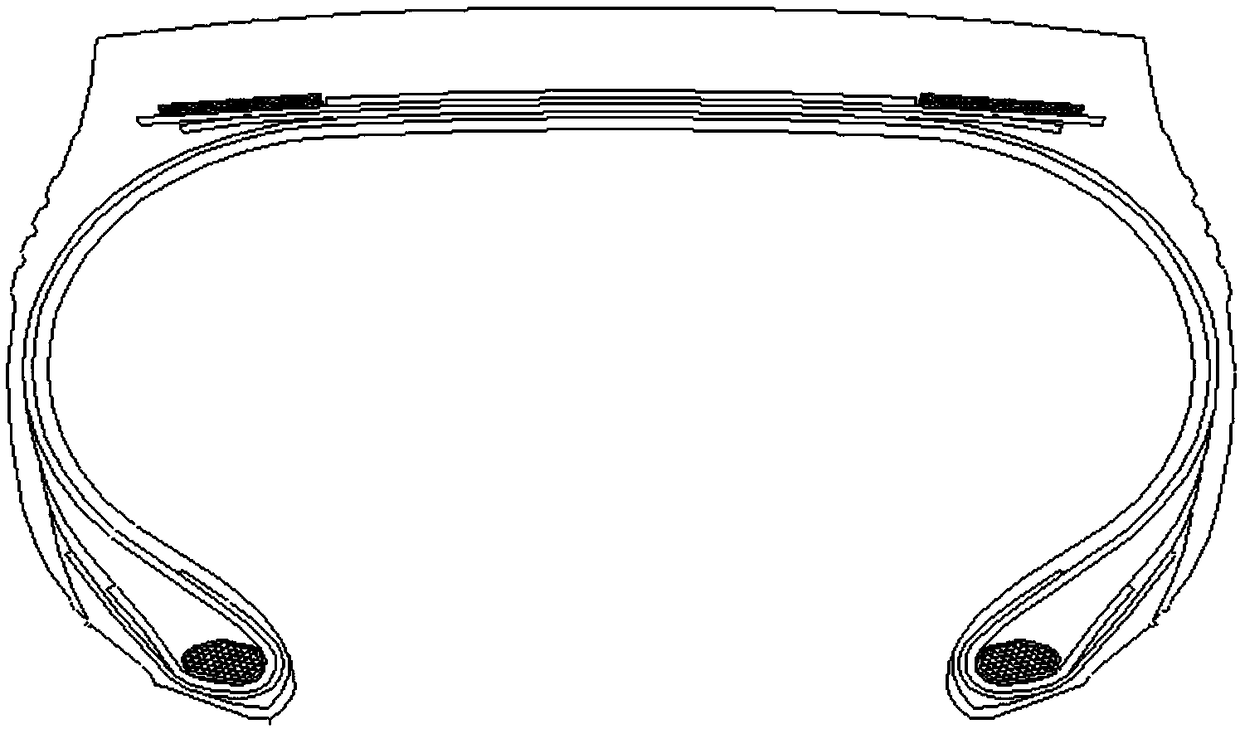

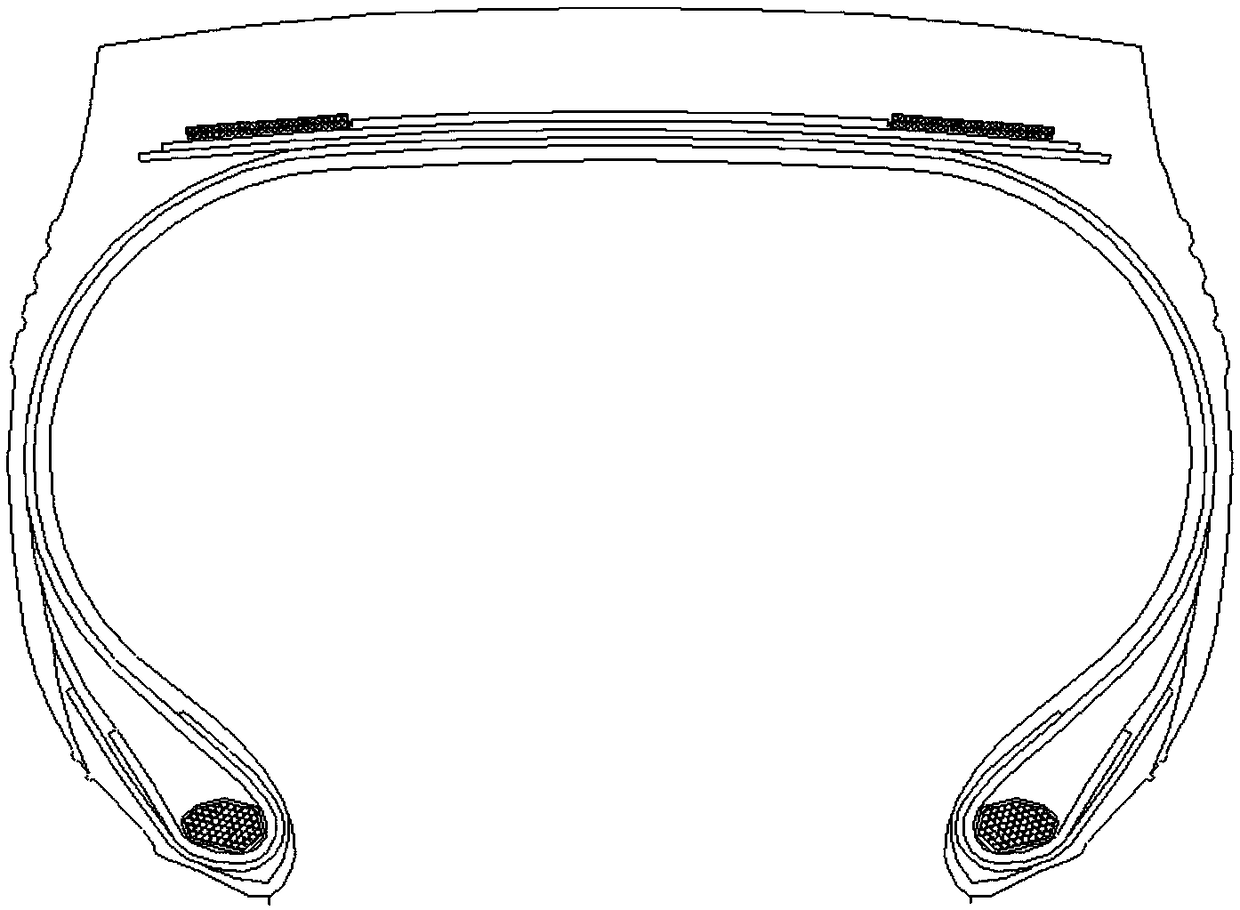

[0030] by figure 1 The belt structure shown is taken as an example to illustrate (refer to Figure 4 mark). In this structure, there are tension-resistant belt layers 3 and 4 intersecting with each other at 10° to 45° to the tire circumferential direction, and a narrow protective belt layer located in the center of the crown covering the tension-resistant belt layer 5. At both ends of the protective belt layer 5 and above the tension-resistant belt layer 4, there are 2 or 3 layers of reinforcing belt layers 6 arranged circumferentially and parallel to each other. The outer endpoints of the reinforcing belt 6 are closer to the centerline of the tread than the wider of the tension-resistant belts 3,4.

[0031] Since the reinforcing belt layers 6 in the above structure are arranged in parallel along the circumferential direction, in the forming and vulcanizing process, it is impossible to compensate for the tension of the belt through angle changes like other tension-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com