a kind of oil tank

A technology for oil tanks and tanks, which is applied in packaging, large containers, transportation and packaging, etc. It can solve problems such as low safety, poor light, and inability to reduce fire hazards efficiently, so as to improve the working environment and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

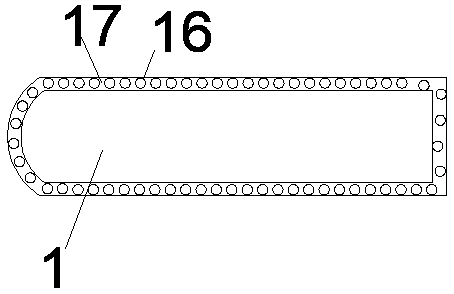

[0019] Embodiment 1. An oil tank including: oil tank body 1, drain port 2, piston rod 3, hydraulic cylinder 4, piston block 5, first outlet 6, second outlet 7, sealed chamber 8, arc Head 9, connecting pipe 10, L-shaped tubular port 11, pressure tank 12, air pump 13, sealed tank 14, oil guide tube 15, gas storage tube 16, protective layer 17, air guide tube 18, gas tank 20, including: oil tank The upper end surface of the body 1 is successively installed with a first outlet 6 and a second outlet 7 communicating with the inner cavity of the oil tank body 1, and a sealed chamber 8 is also installed on the upper end surface of the oil tank body 1; A circular arc head 9 is provided on the left side of 1; a connecting pipe 10 and an L-shaped tubular port 11 communicating with the inner cavity of the oil tank body 1 are installed on the left end surface of the circular arc head 9 from top to bottom; a communicating pipe The left end of 10 is connected to the L-shaped tubular port 11; ...

Embodiment 2

[0020] Embodiment 2. An oil tank, wherein: the protective layer 17 is made of high temperature resistant rubber, and the outer surface of the protective layer 17 is embedded with uniformly distributed wear-resistant particles. The rest is the same as in Example 1.

Embodiment 3

[0021] Embodiment 3. An oil tank, wherein: the wear-resistant particles are wear-resistant metal particles or wear-resistant ceramic particles. The rest is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com