Track vibration damping device

A vibration damping device and rail technology, which is applied in the direction of rails, roads, buildings, etc., can solve the problems of reducing the service life of rails, affecting vibration and noise reduction, accelerating rail wear and other problems, and achieving the effect of reducing rail vibration and adjusting characteristic frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

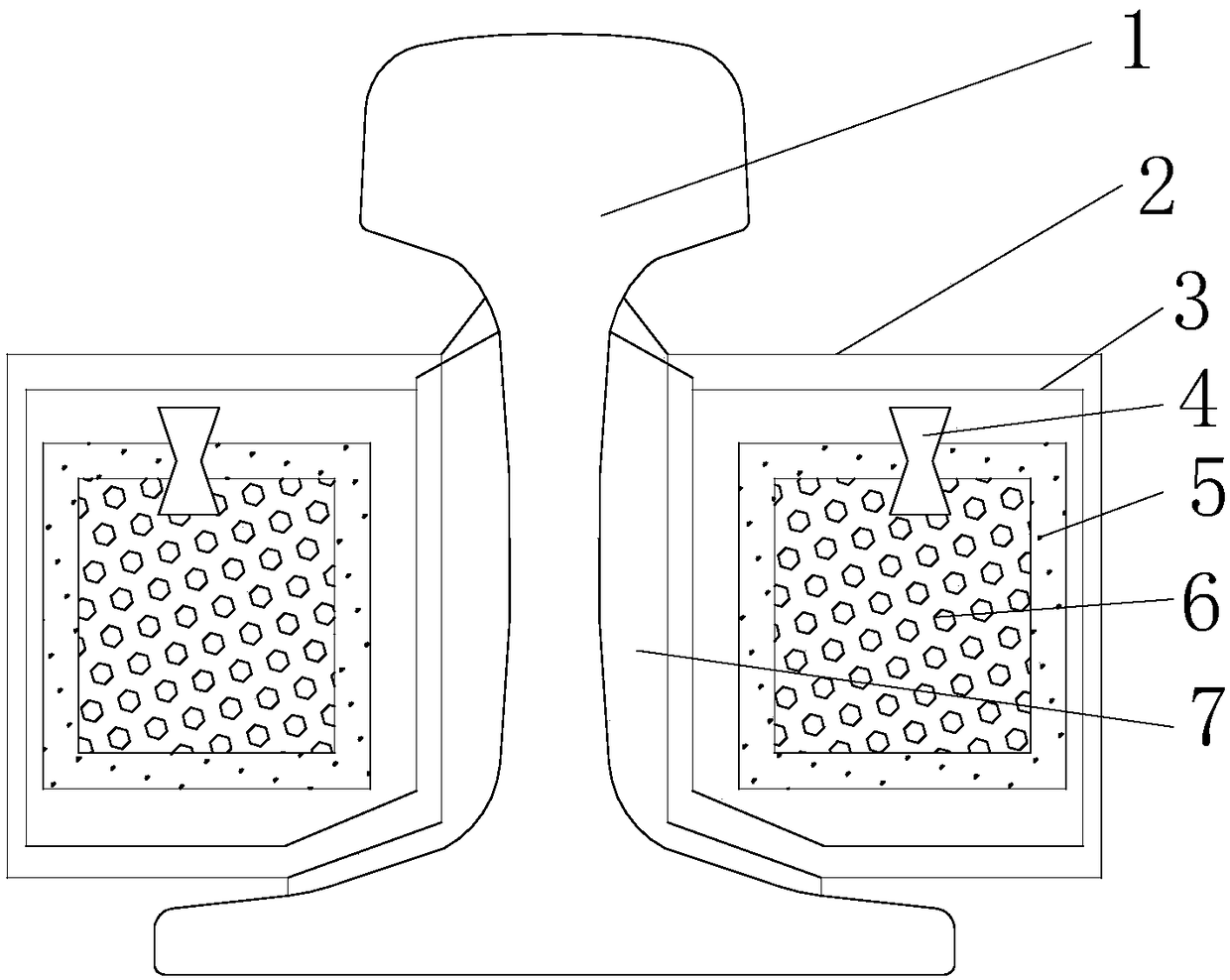

Image

Examples

Embodiment 2

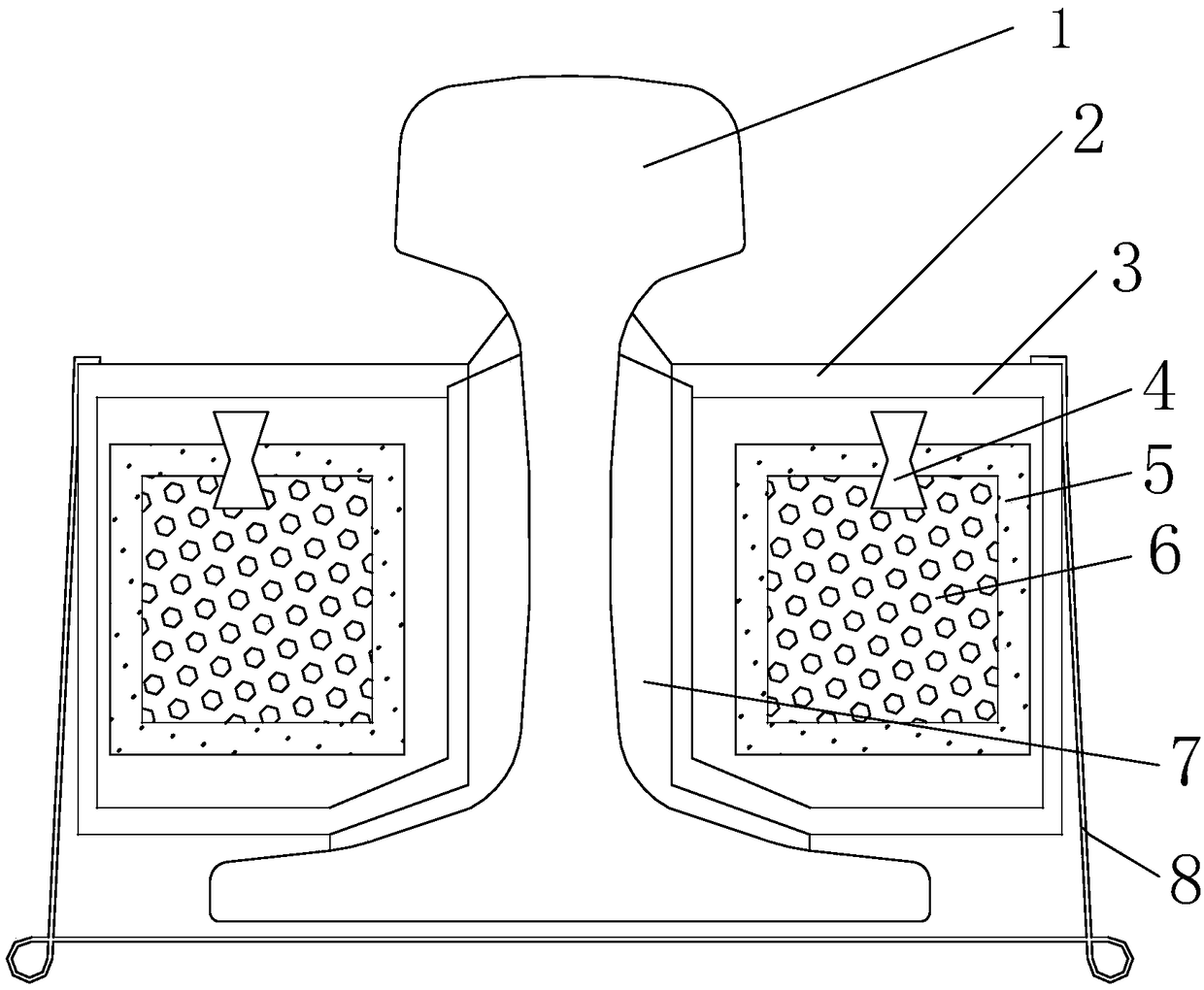

[0035] This embodiment is basically the same as Embodiment 1. For brevity of description, in the description of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1:

[0036] Such as figure 2 As shown, in this embodiment, the rail vibration damping device further includes an elastic clamp 6 for clamping the vibration damping unit on the steel rail 1 to further ensure a reliable connection between the vibration damping unit and the steel rail 1. Preferably, the number of elastic clamps 6 is multiple, and the plurality of elastic clamps 6 are arranged at intervals along the longitudinal direction of the steel rail 1.

[0037] Specifically, the elastic clip 6 has a U-like structure, and includes two clamping portions and a connecting portion for connecting the two clamping portions. The clamping portions respectively abut against the side of the outer box 2 away from the rail waist. Loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com